Production method for composite insulation pipe

A technology of composite heat preservation and production method, which is applied in the field of composite pipes, can solve problems such as slipping of outer pipes, easy damage of composite pipes, shrinkage of inner pipes, etc., and achieve the effects of prolonging service life, preventing pipe bursting, and not being easy to fall off and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

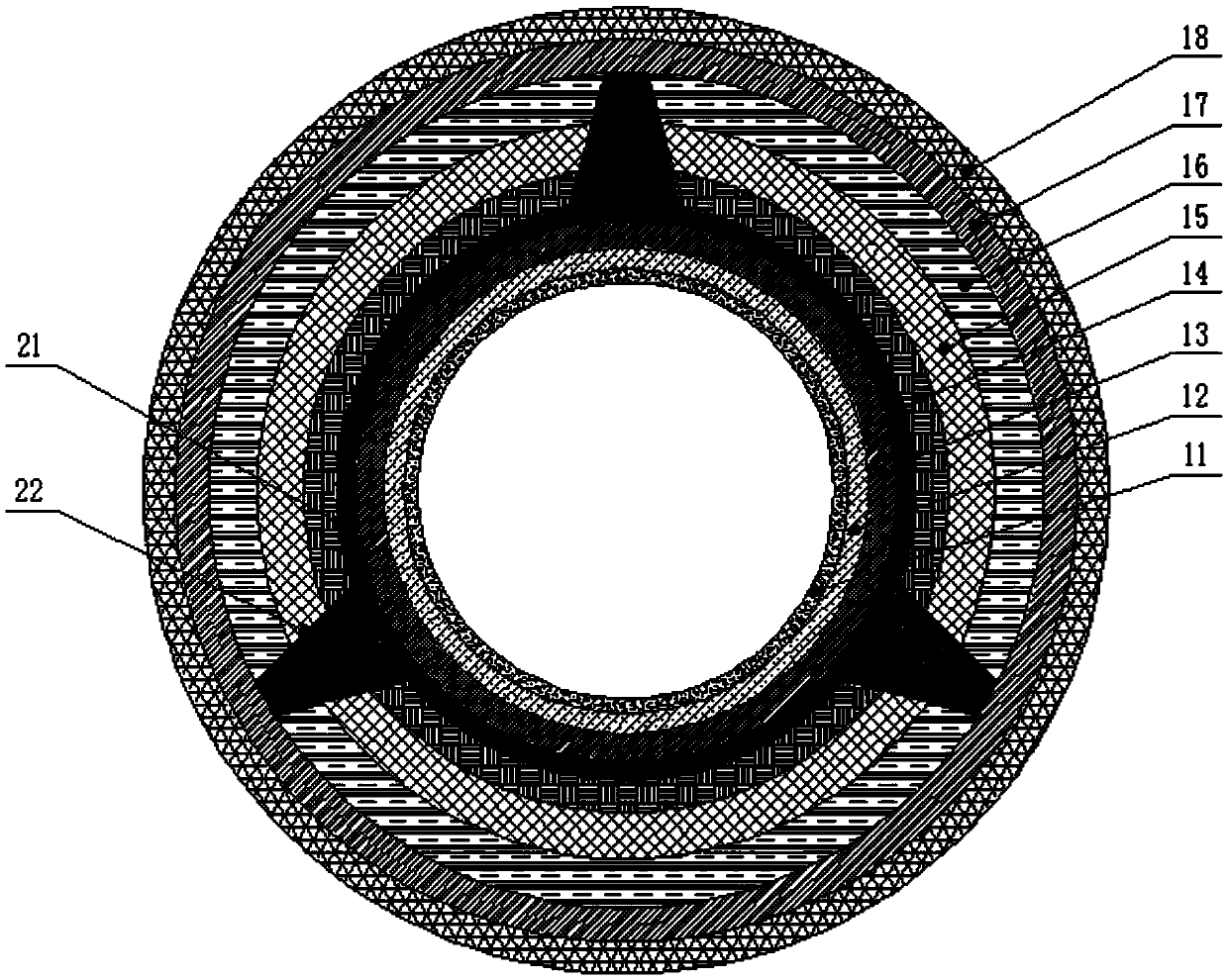

[0031] according to figure 1 As shown, a heat preservation pipe includes nano-silver coating 11, porous silica gel pipe 12, stainless steel pipe 13, high temperature resistant fiber felt 14, sodium silicate heat preservation pipe 15, polyurethane foam layer 16, carbon steel pipe from outside to inside 17 and three layers of PE coating 18, a positioning ring 21 is arranged between the carbon steel pipe and the stainless steel pipe, and the outer wall of the positioning ring extends outward to form several positioning bosses 22, and the positioning ring is fixedly sleeved on the The outer wall of the stainless steel pipe, the outer wall of the positioning boss is fixed on the inner wall of the carbon steel pipe.

[0032] The stainless steel pipe includes the following components by weight: 700-900 parts of steel scrap, 20-40 parts of ferroboron, 0.5-2 parts of carbon, 5-10 parts of silicon, 5-10 parts of manganese, 150-200 parts of chromium, nickel 60-100 parts and sulfur 0.1-0...

Embodiment example 2

[0034] A method for producing a composite insulation pipe, comprising the following steps:

[0035] S1: Preparation of stainless steel pipe: put the following components by weight into a melting furnace for melting: 700 parts of steel scrap, 20 parts of ferroboron, 0.5 parts of carbon, 5 parts of silicon, 5 parts of manganese, 150 parts of chromium, 60 parts of nickel and sulfur 0.1 part; after the molten steel is melted, a small amount of aluminum is added for deoxidation, and the slag is removed from the furnace at 1560°C; after the furnace is left to stand and naturally cooled for 150s, the centrifugal casting of stainless steel pipes is carried out; the centrifugal casting condition is that the line speed of the centrifuge is 30m / s, pouring thickness is 5mm;

[0036] S2: Preparation of composite tube A: Spray nano-silver coating on one side of the porous silica gel sheet to form a coating, and then roll it into a tube shape;

[0037] S3: Preparation of the composite pipe ...

Embodiment example 3

[0045] A method for producing a composite insulation pipe, comprising the following steps:

[0046] S1: Preparation of stainless steel pipe: put the following components by weight into a melting furnace for melting: 900 parts of steel scrap, 40 parts of ferroboron, 2 parts of carbon, 10 parts of silicon, 10 parts of manganese, 200 parts of chromium, 100 parts of nickel and sulfur 0.5 parts; after the molten steel is melted, a small amount of aluminum is added for deoxidation, and the slag is removed from the furnace at 1600°C; after the furnace is left to stand, and after natural cooling for 200s, the centrifugal casting of stainless steel pipes is carried out; the centrifugal casting condition is centrifuge line speed 40m / s, pouring thickness is 10mm;

[0047] S2: Preparation of composite tube A: Spray nano-silver coating on one side of the porous silica gel sheet to form a coating, and then roll it into a tube shape;

[0048] S3: Preparation of the composite pipe B: the out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com