Method for rapidly preparing patterned doped graphene by ultraviolet laser

An ultraviolet laser and graphene technology, applied in graphene, nano-carbon and other directions, can solve the problems of low processing efficiency, cumbersome process, limited moving range, etc., and achieve the effect of high processing efficiency, high processing quality and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

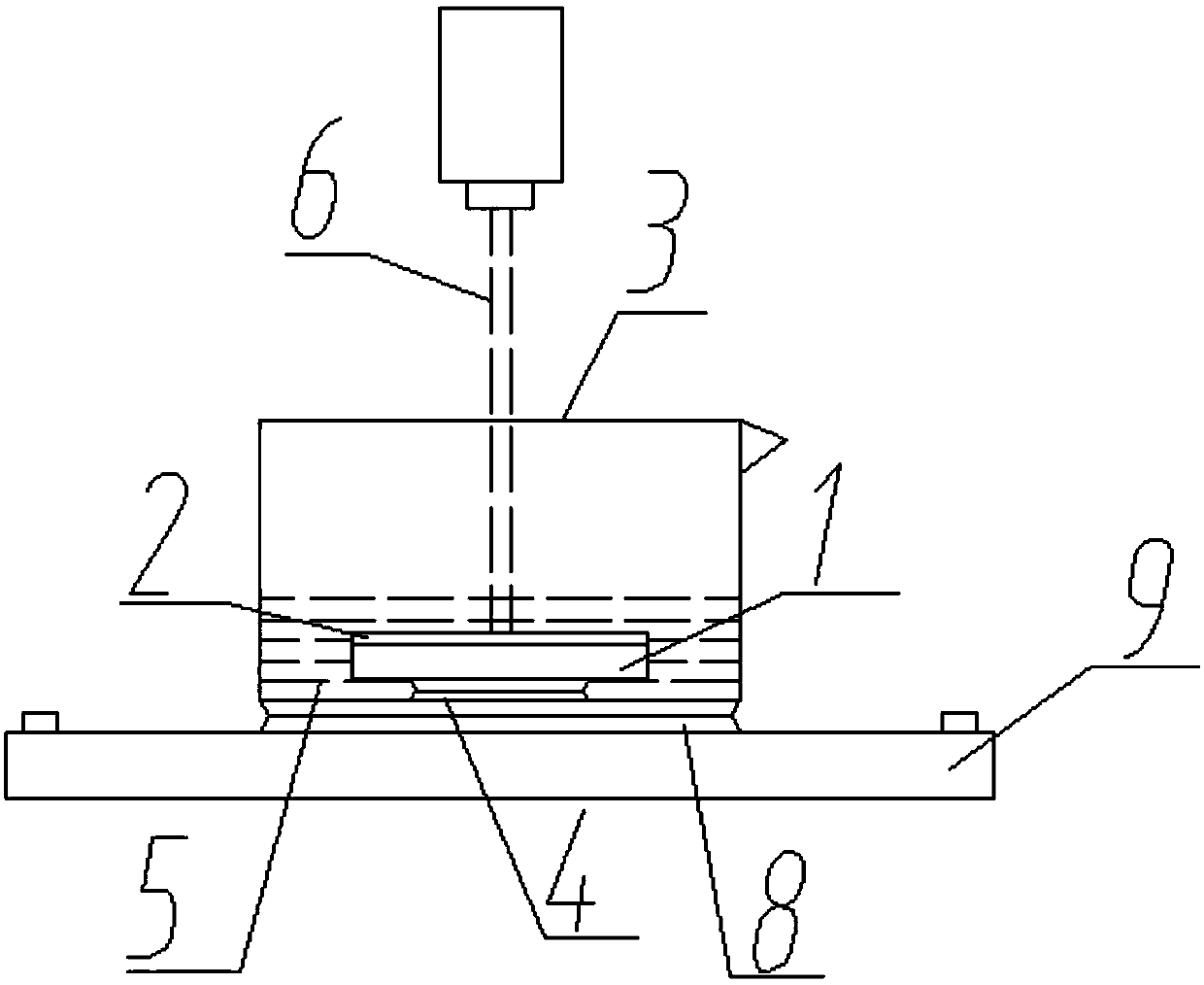

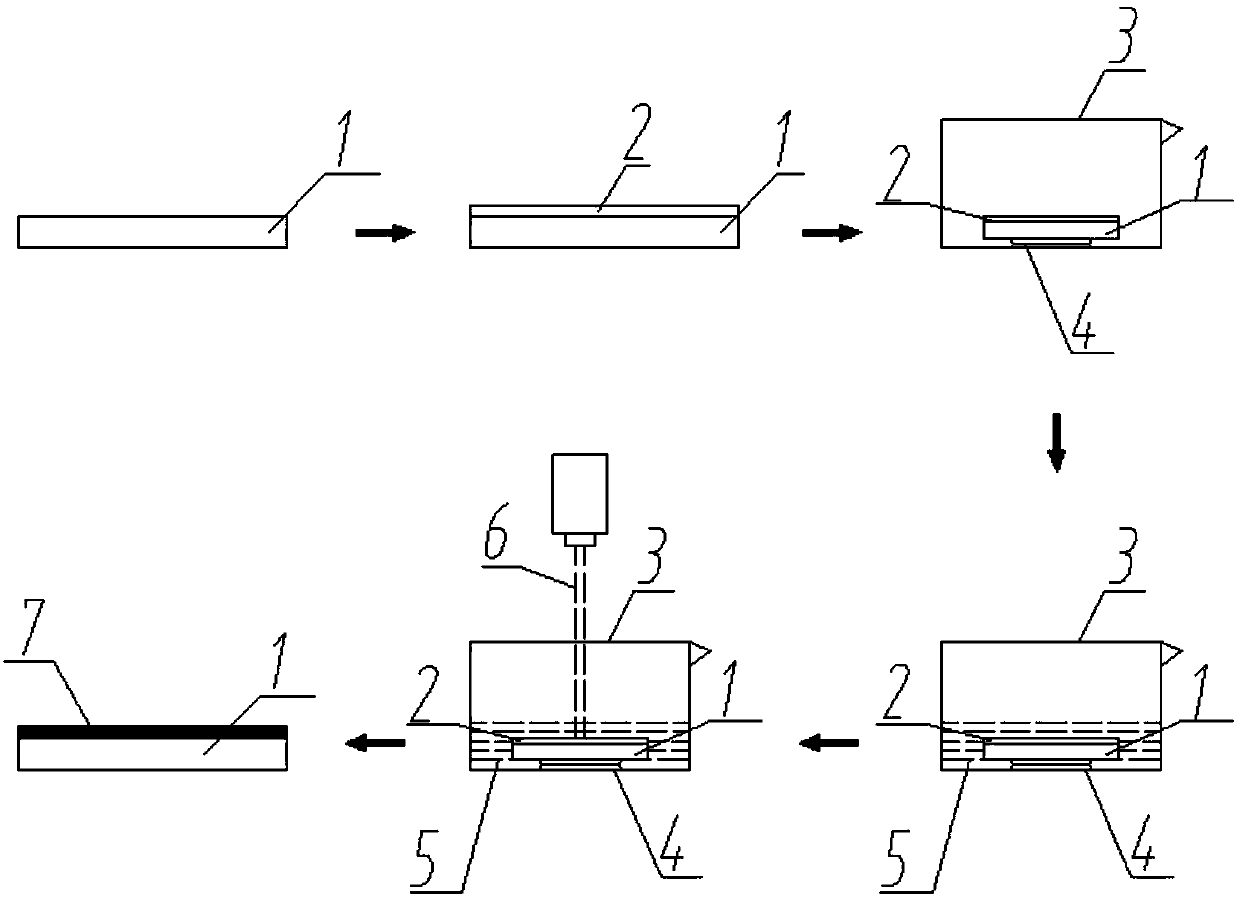

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

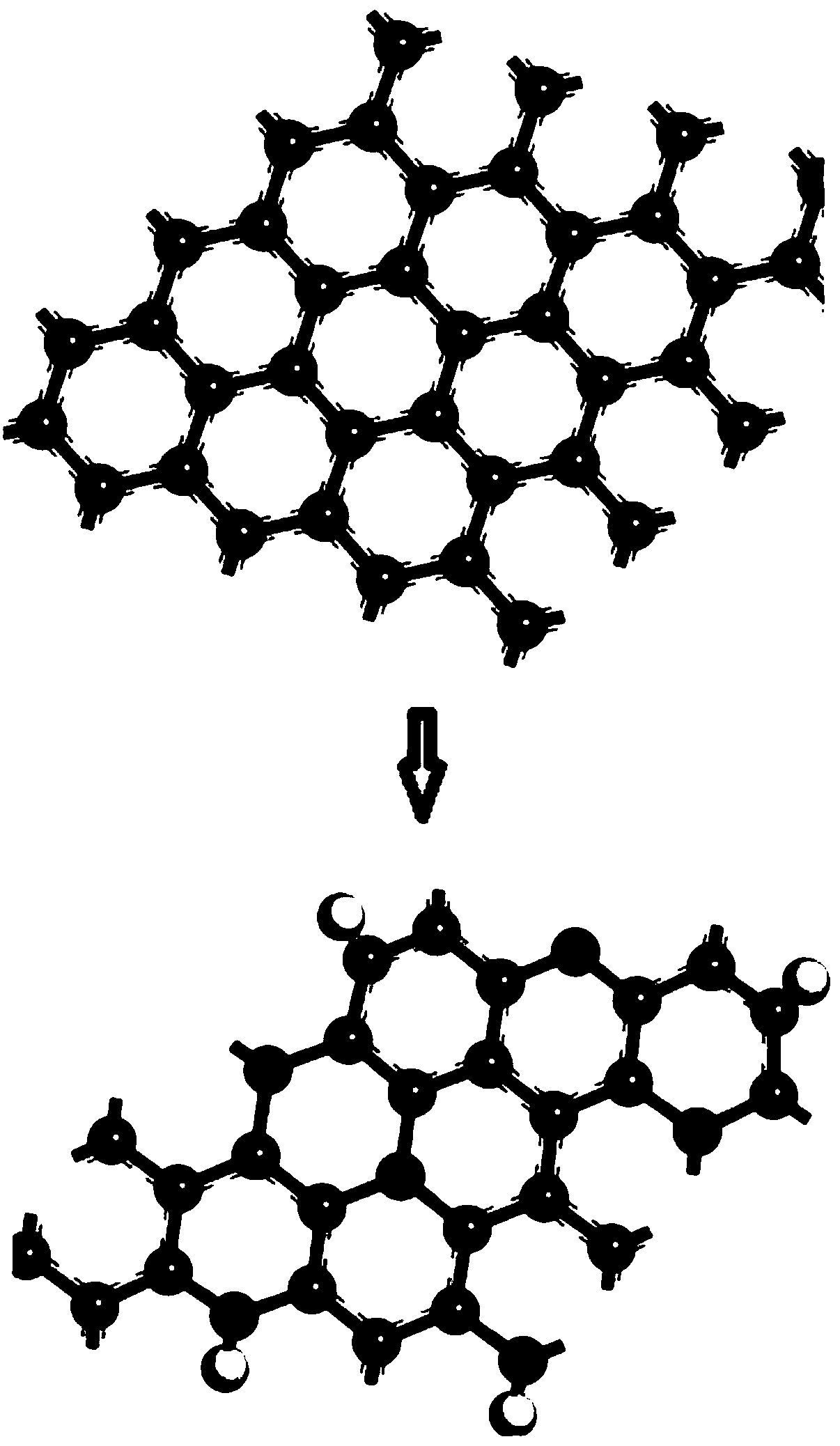

[0025] Such as Figure 1-2 Shown, a kind of method for rapidly preparing patterned doped graphene by ultraviolet laser, it comprises the following steps:

[0026] a. Configure a carbon source solution; in the step a, the carbon source solution is prepared by fully mixing polyimide and absolute ethanol at a volume ratio of 1:1.

[0027] b. To make a carbon source liner, take a base plate 1 suitable for 2cmx2cm, said base plate 1 is made of copper; place the base plate 1 on the workbench of the glue homogenizer, and use a pipette to take the carbon source solution configured above and drop it on On the upper surface of the liner, set the parameters of the homogenizer to 400 rpm for the low speed, 1000 rpm for the high speed, and 50 seconds for the spin coating time to complete the processing of the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com