A kind of aerobic fermentation process of organic waste

A technology of organic waste and fermentation process, applied in the direction of organic fertilizer, climate change adaptation, etc., can solve the problems of complex structure of fermentation equipment, wide area and complex treatment process of organic waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

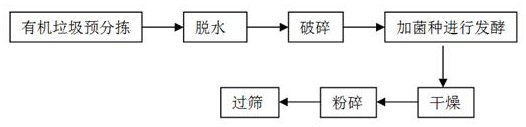

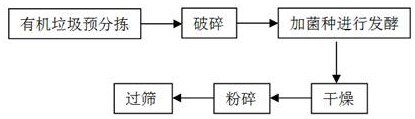

[0041] Please refer to figure 1 as shown, figure 1 It is a process flow chart of the aerobic fermentation of organic waste in the present invention. In this embodiment, an aerobic fermentation process of organic waste is carried out in this embodiment. Vegetable waste is fermented, including pre-sorting of organic waste, including the following step:

[0042] Step 1. Put 2T of pre-sorted organic waste into the horizontal fermentation tank of the waste treatment device;

[0043] Step 2, turn on the machine, make the horizontal fermenter rotate to crush the organic waste, add 1.0% (mass ratio) high-temperature microaerophilic bacteria, stir the high-temperature microaerophilic bacteria and the crushed organic waste evenly, and mix them evenly at 65°C Fermentation at temperature;

[0044] Step 3: During the fermentation process of organic waste, the suction pump is turned on to pump the fermentation gas and water vapor in the horizontal fermentation tank into the cooling water...

Embodiment 2

[0050] Please refer to figure 1 as shown, figure 1 It is a process flow diagram of the aerobic fermentation of organic waste in the present invention. In this embodiment, this embodiment performs fermentation treatment on kitchen organic waste, including pre-sorting of organic waste, including the following steps:

[0051] Step 1. Put the 3T pre-sorted organic waste into the horizontal fermentation tank of the waste treatment device;

[0052] Step 2, heating the horizontal fermenter to 80°C to dehydrate the organic waste;

[0053] Step 3, turn on the machine, make the horizontal fermenter rotate to crush the organic waste, add 1.5% (mass ratio) high-temperature microaerophilic bacteria, stir the high-temperature microaerophilic bacteria and the crushed organic waste evenly, and mix them evenly at 80°C Fermentation at temperature;

[0054] Step 4: During the fermentation process of organic waste, the suction pump is turned on to pump the fermentation gas and water vapor in t...

Embodiment 3

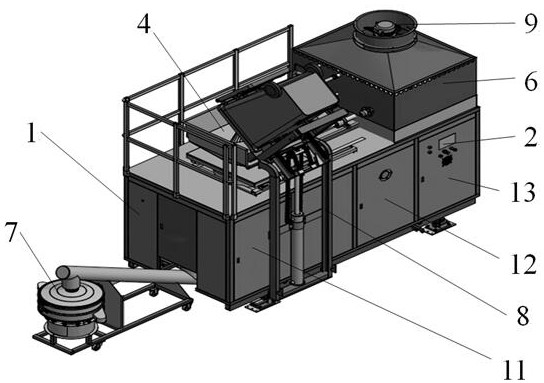

[0061] like Figure 3-4 as shown, image 3 It is the external structural diagram of the garbage treatment device of the equipment for realizing the aerobic fermentation of organic garbage in the present invention, Figure 4 It is the internal structure diagram of the garbage disposal device of the present invention.

[0062] The garbage disposal device includes a closed box body 1 and an automatic control system 2 , and the automatic control system 2 is located outside the box body 1 .

[0063] The casing 1 includes a fermentation chamber 11 and a power chamber 12. The fermentation chamber 11 is provided with a horizontal fermenter 3, and the upper part of the fermentation chamber 11 is provided with a feed hopper 4 communicating with the feed port of the horizontal fermenter 3. The tank body of the horizontal fermenter 3 is wrapped with a heating device, the exhaust port of the horizontal fermenter 3 is connected to a suction pump 5 , and the other end of the suction pump 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com