Method for preparing TiO2 multi-scale micro-nano composite structure on titanium substrate

A technology of micro-nano composite structure and micro-nano structure, applied in ion implantation plating, metal material coating process, coating, etc., can solve problems such as difficult recycling and reuse, easy agglomeration, easy generation of impurities, etc., to achieve Accelerated photogenerated electron transfer rate, small charge transfer impedance, improved adsorption performance and light absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

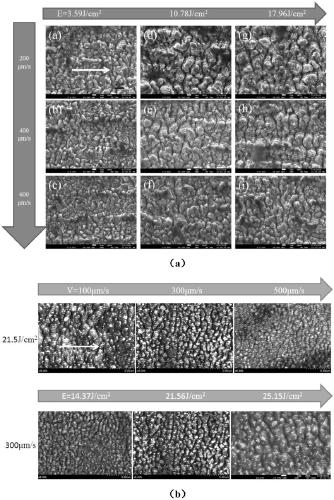

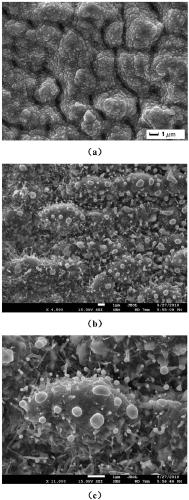

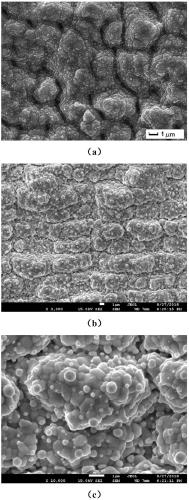

[0026] Example 1: First, a femtosecond laser is used to etch the surface of a pure Ti sheet in deionized water to prepare a first-level micron structure. The laser parameters are: frequency: 1khz, pulse width 187fs, laser energy density: E=10.78J / cm 2 , scanning speed: v=400μm / s; then place the Ti sheet after laser etching in absolute ethanol and ultrasonically clean it for 5 minutes, and then use magnetron sputtering for 15 minutes to coat gold film on the surface of the Ti sheet after ultrasonic cleaning; The final Ti sheet was placed in a muffle furnace for heat treatment at a heating rate of 5°C / min. After the temperature was raised to 750°C, the temperature was kept for 4 hours, and then cooled with the furnace temperature to prepare a secondary nanostructure, and finally a rutile-type nanostructure loaded with gold particles was obtained. TiO 2 Multiscale composite micro-nanostructures.

Embodiment 2

[0027] Example 2: First, a femtosecond laser is used to etch the surface of a pure Ti sheet in deionized water to prepare a first-level micron structure. The laser parameters are: frequency: 1khz, pulse width 187fs, laser energy density: E=10.78J / cm 2, scanning speed: v=400μm / s; then place the Ti sheet after laser etching in absolute ethanol and ultrasonically clean it for 5 minutes, and then use magnetron sputtering for 15 minutes to coat gold film on the surface of the Ti sheet after ultrasonic cleaning; The final Ti sheet was placed in a muffle furnace for heat treatment at a heating rate of 5°C / min. After the temperature was raised to 800°C, it was kept for 8 hours, and cooled with the furnace temperature to prepare a secondary nanostructure, and finally obtained a rutile-type nanostructure loaded with gold particles. TiO 2 Multiscale composite micro-nanostructures.

Embodiment 3

[0028] Example 3: First, a femtosecond laser is used to etch the surface of a pure Ti sheet in deionized water to prepare a first-level micron structure. The laser parameters are: frequency: 1khz, pulse width 187fs, laser energy density: E=10.78J / cm 2 , scanning speed: v=400μm / s; then place the Ti sheet after laser etching in absolute ethanol and ultrasonically clean it for 5 minutes, and then use magnetron sputtering for 15 minutes to coat gold film on the surface of the Ti sheet after ultrasonic cleaning; The final Ti sheet was placed in a muffle furnace for heat treatment at a heating rate of 5°C / min. After the temperature was raised to 800°C, it was kept for 4 hours, and cooled with the furnace temperature to prepare a secondary nanostructure, and finally a rutile-type nanostructure loaded with gold particles was obtained. TiO 2 Multiscale composite micro-nanostructures.

[0029] Compared with Example 1 and 3, the laser parameters are the same, the heat treatment holding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com