Ablative pulse plasma thruster based on multi-anode electrode structure

A technology of pulsed plasma and electrode structure, applied in the direction of using plasma, thrust reverser, machine/engine, etc., can solve the problem of plasma that cannot effectively leave the nozzle, the magnetic field strength at the upper end of the magnetic nozzle increases, and the magnetic field increases in volume And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

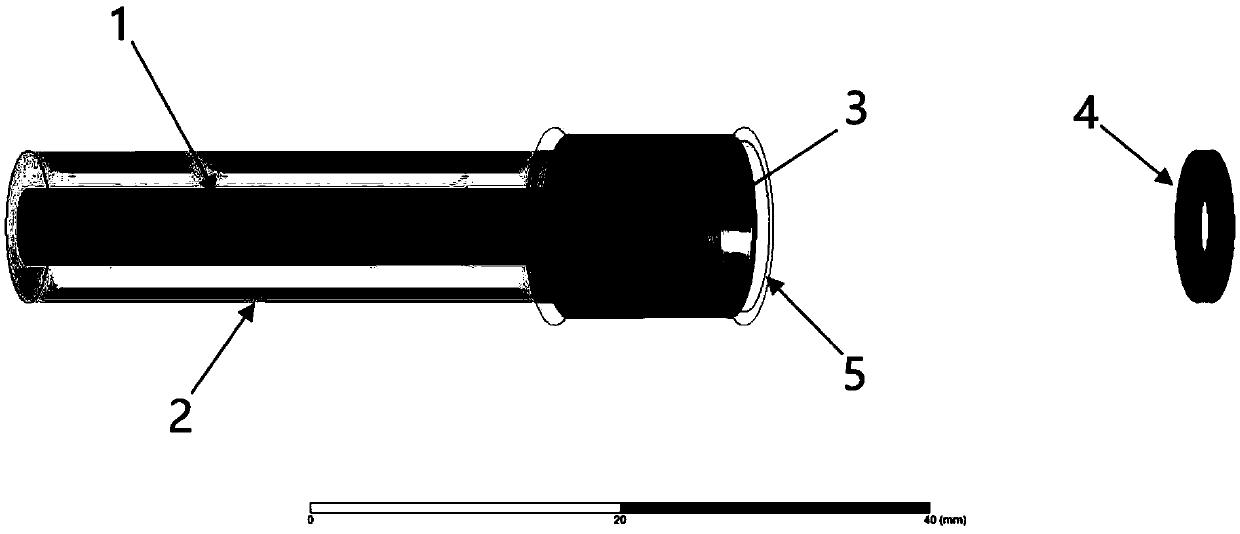

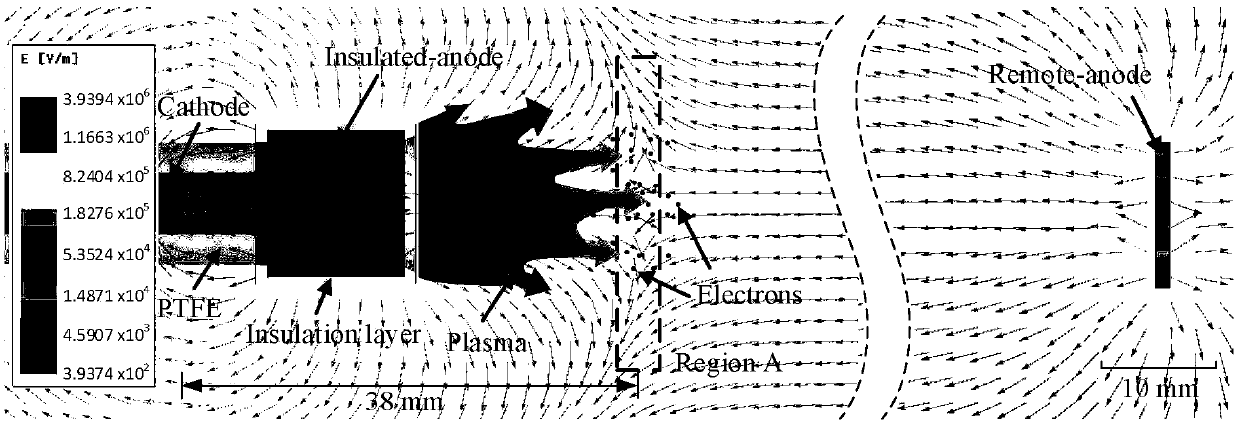

[0065] The embodiment of the present invention provides an ablation-type pulsed plasma thruster based on a multi-anode electrode structure, which adopts a coaxial electrode structure, uses two anodes to respectively realize the triggering of surface discharge and the conduction of the circuit, and realizes the process of plasma propagation in full bondage.

[0066] The embodiment of the present invention adopts the triggering mechanism of the three-junction point of the cathode to induce creeping discharge between the cathode and the anode. The separation of the electrodes and the insulating medium will lead to the interruption of the creepage path; the large distance between the electrodes will cause the decrease of the electric field strength of the cathode triple junction, making it difficult to emit initial electrons; before the arc current is formed, it is difficult to form enough plasma The body connects the cathode and anode. But as long as the strong electric field at...

Embodiment 2

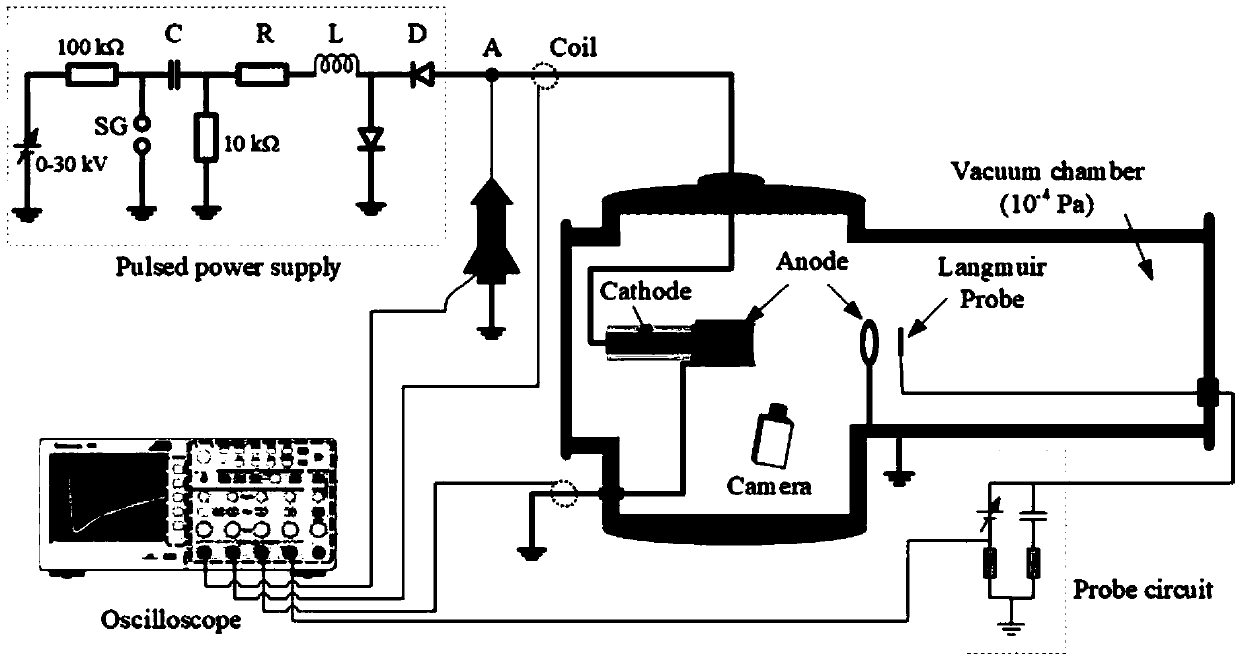

[0098] This embodiment provides an experimental system of an ablation-type pulsed plasma thruster based on a multi-anode electrode structure, and the realization structure of the experimental system is as follows image 3 As shown, the specific contents may include the following:

[0099] An application system of a vacuum metal arc thruster based on a multi-anode structure provided in this embodiment includes: a pulse power supply, a vacuum discharge device and a diagnosis system.

[0100] Pulse power supplies use energy storage capacitors as the energy source for discharge. Before discharging, the energy storage capacitor C is charged to a specific voltage, and then the ball gap switch SG is turned on through a pulse signal; at this time, the voltage of the energy storage capacitor C starts to be applied to both ends of the electrodes through the current limiting resistor R and the inductor L. Therefore, a discharge occurs due to breakdown of the vacuum gap. The diode D in ...

Embodiment 3

[0131] This embodiment provides a method for optimizing the plasma plume for an ablation-type pulsed plasma thruster based on a multi-anode electrode structure, specifically as follows:

[0132] Firstly, a method to form θ-pinch in multi-anode electrode structure APPT basically by rational arrangement is proposed. Such as Figure 16 As shown, a helical coil is placed outside the PTFE tube, the left side of the coil is connected to the cathode, and the right side is connected to the pulse power supply. when current i θ When flowing out of the helical coil, the surface of the plasma column will induce an induced current in the θ direction At the same time, the current i θ generated magnetic field is the Z-axis direction. A radial pinch force is generated on the surface of the plasma column, confining the plasma toward the center. This theta pinch is unique compared to the application of an external magnetic field in that it is formed by its own discharge current. There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com