Transformer low-voltage conductive rod temperature-measuring device based on induction power-taking technology

A technology of inductive power taking and temperature measuring device, which is applied in measuring devices, thermometers using electrical devices, and thermometers with electrical/magnetic components directly sensitive to heat, etc. Inconvenient use and other problems, to shorten the development cycle of human-computer interaction, reduce the probability of accidents caused by heat, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

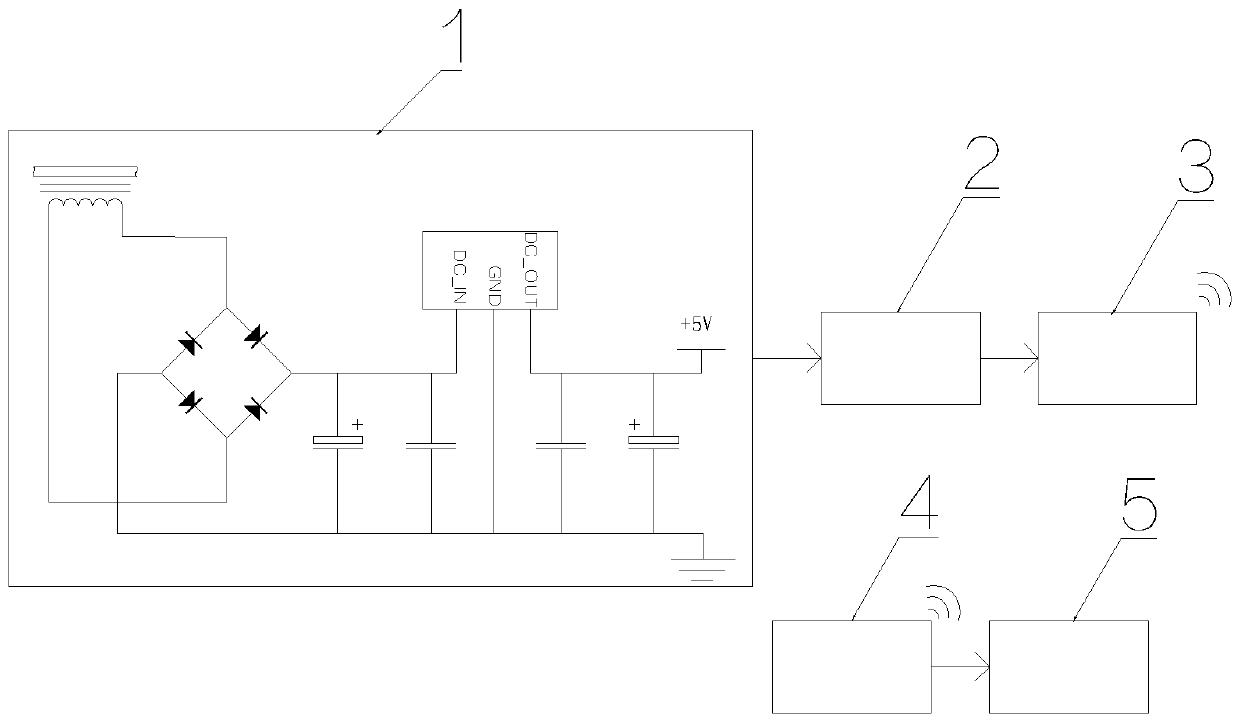

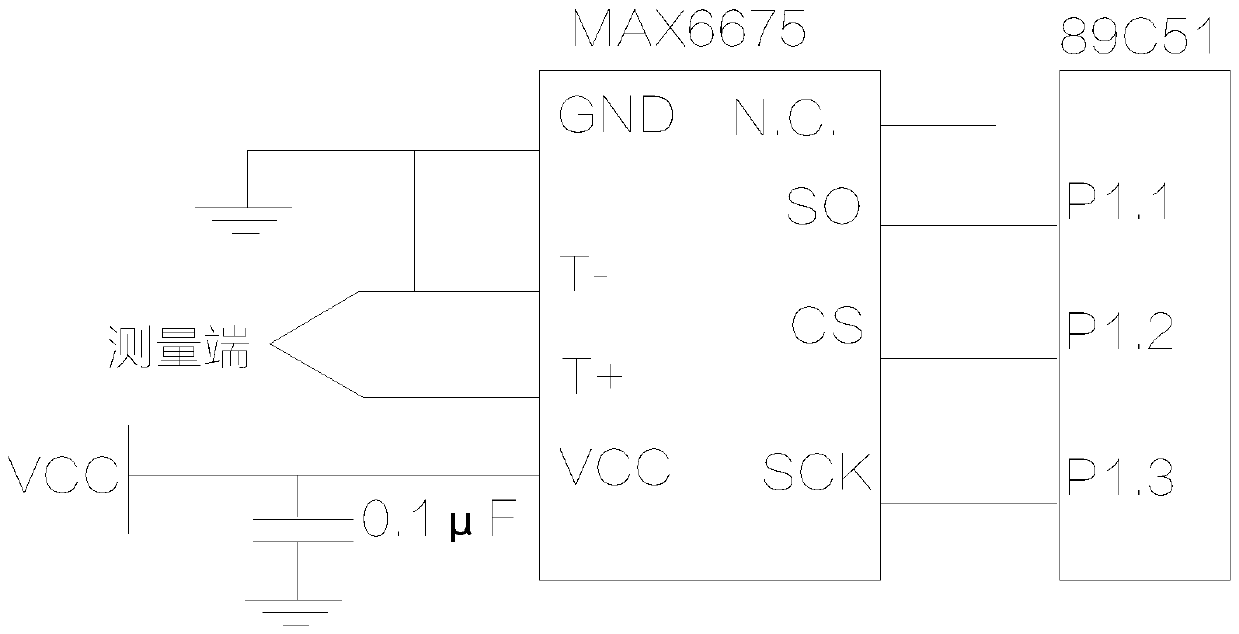

[0036] Such as Figure 1-2 As shown, a transformer low-voltage conductive rod temperature measuring device based on inductive power-taking technology includes an inductive power-taking part 1 , a temperature collecting part 2 , a wireless transmitting part 3 , a wireless receiving part 4 and a temperature display part 5 .

[0037]The induction power-taking part 1 includes a silicon steel sheet, a coil, a rectifier circuit, and a voltage converter. The silicon steel sheet is wound on the low-voltage outlet line of the transformer. The silicon steel sheet is provided with a power-taking coil, which is connected to the rectifier circuit. The voltage converter is connected, and the power converter outputs low-voltage direct current as the power supply of the temperature collecting part 2 and the wireless transmitting part 3 . The inductive power-taking part 1 adopts micro-magnetic energy harvesting technology to avoid direct use of transformer voltage for power supply, which will ...

Embodiment 2

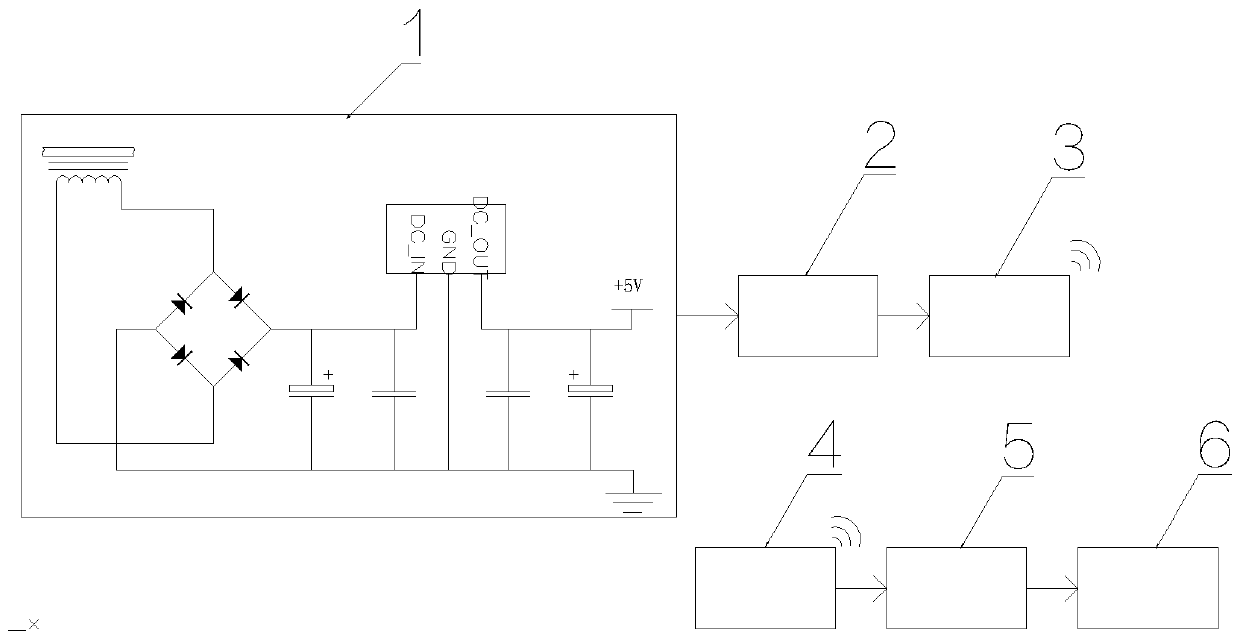

[0068] Such as image 3 As shown, the structures of this embodiment and Embodiment 1 are basically the same, and the difference is that a signal output interface 6 is also provided on the liquid crystal display of the temperature display part 5, which is used to output the three-phase temperature to other automation equipment, through automation Equipment for remote monitoring and automatic operation.

Embodiment 3

[0070] Such as Figure 4 As shown, the structures of the present embodiment and the second embodiment are basically the same, and the difference is that a relay interface 7 is set on the liquid crystal display of the temperature display part 5, the relay interface 7 is connected with the relay, and the relay is connected with the buzzer. When the alarm threshold is reached, the relay pulls in and is used to drive the external buzzer to sound and give sound reminders to the power distribution inspectors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com