High specific surface hollow tubular micromotor, preparation method and application

A micro-motor, high specific surface technology, applied in the direction of material electrochemical variables, can solve the problems of high cost, small specific surface area, difficult to control surface structure, etc., and achieve the effect of low cost, high biocompatibility and abundant yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

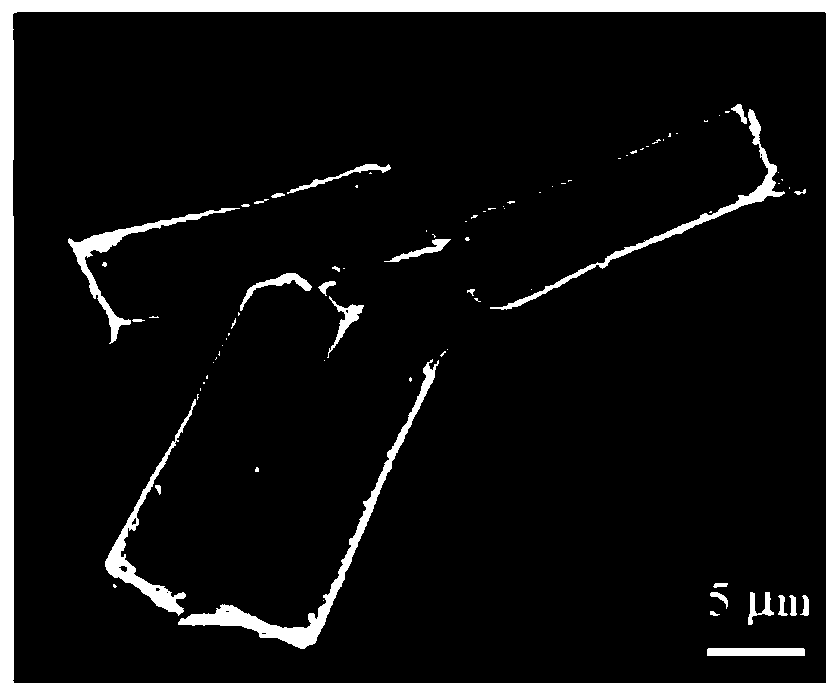

[0050] In the specific preparation process, including the preparation of polyethylene dioxythiophene PEDOT support outer layer, the electrodeposition preparation of Fe intermediate layer and MnO 2 Electrodeposition preparation of catalytic inner layers.

[0051] As a preferred solution, in the high specific surface hollow tubular micro motor, the deposited charge of the PEDOT support outer layer is 0.2-0.4C, the deposited charge of the Fe intermediate layer is 0.3-0.6C, MnO 2 The amount of deposited charge is 0.1 ~ 0.5C.

[0052] The particularly preferred specific surface structure is the nanoscale fish scale intercalation structure, which can maximize the chemically driven contact area and play the role of MnO 2 Decomposition synergy as a catalyst. Among them, preferably, the deposition charge of the Fe intermediate layer is 0.4C.

[0053] As shown in the accompanying drawings, the preparation of the high specific surface hollow tubular micromotor of the present invention...

Embodiment 1

[0072] In embodiment 1, the electrochemical deposition of preferred each step all adopts constant potential method, and deposition parameter is as follows:

[0073] The electrodeposition parameter setting of the PEDOT support outer layer: set the deposition voltage to 0.8-1.0V, and deposit a charge of 0.2-0.4 coulombs;

[0074] Parameter setting of the electrodeposition of the Fe interlayer: set the deposition voltage to -0.8--1.2V, and deposit a charge of 0-0.6 coulomb; especially preferably a charge of 0.3-0.6 coulomb.

[0075] MnO 2 The electrodeposition parameter setting of the inner layer: set the deposition voltage to 0.8-1.2V, and deposit 0.1-0.5 coulombs of charge.

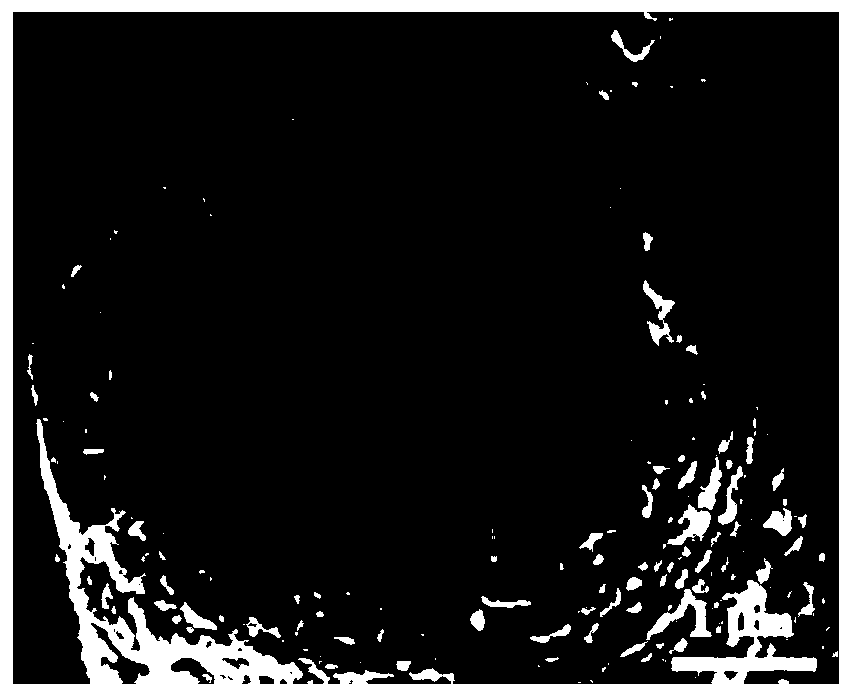

[0076] As described in the previous steps, through the above electrolyte system and electrochemical deposition treatment, the PEDOT outer layer, Fe middle layer and MnO 2 The polycarbonate film in the inner layer is finally polished and dissolved to obtain a hollow tubular micro-motor (PEDOT / Fe-MnO 2 ),...

Embodiment 2

[0088] Using the electrochemical deposition method of the above steps 1-4, and using the electrolyte system and the three-electrode system in the above-mentioned embodiment, a PEDOT outer layer, an Fe middle layer and MnO are prepared. 2 The polycarbonate film in the inner layer is finally polished and dissolved to obtain a hollow tubular micro-motor (PEDOT / Fe-MnO 2 ), which has polyethylenedioxythiophene as the supporting outer layer of hollow microtubes and Fe-doped MnO 2 The inner layer, wherein the electrodeposition parameters are as follows:

[0089] The electrodeposition parameter setting of the PEDOT support outer layer: set the deposition voltage to +0.8V, and deposit a charge of 0.2 to 0.4 coulombs;

[0090] Electrodeposition parameter setting of the Fe interlayer: set the deposition voltage to -1.0V, and deposit a charge of 0.3 coulombs;

[0091] MnO 2 The electrodeposition parameter setting of the inner layer: the deposition voltage is set to 1.0V, and the amount...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com