Preparation process of a carbon fiber composite reflector

A composite material and preparation technology, which is applied in mirrors, instruments, optics, etc., can solve the problems of poor conductivity, inability to guarantee isotropic paving, layer angle error, etc., and achieve the effect of simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The parameters of the long-wave infrared carbon fiber mirror to be prepared are as follows: the thickness is 4.8 mm, the diameter is 200 mm, the radius of curvature is 700 mm, and the RMS surface accuracy is λ / 40 (λ=10.6 μm).

[0032] The preparation process of the above-mentioned long-wave infrared carbon fiber mirror is as follows:

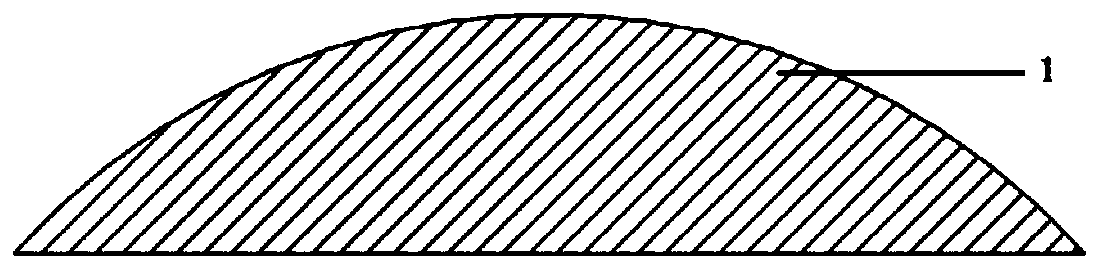

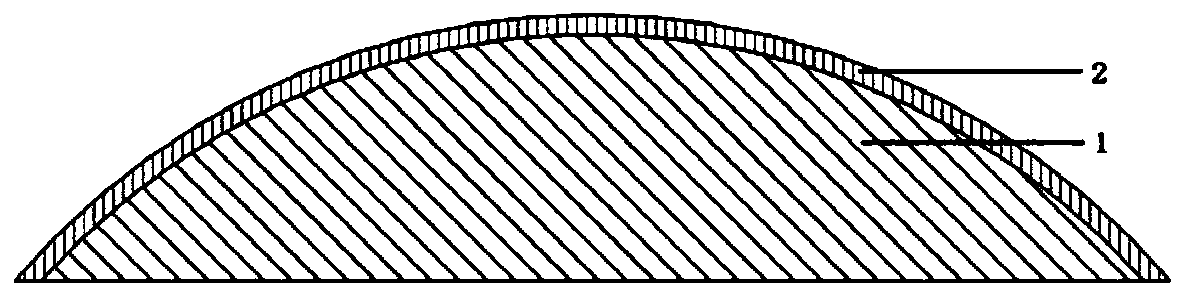

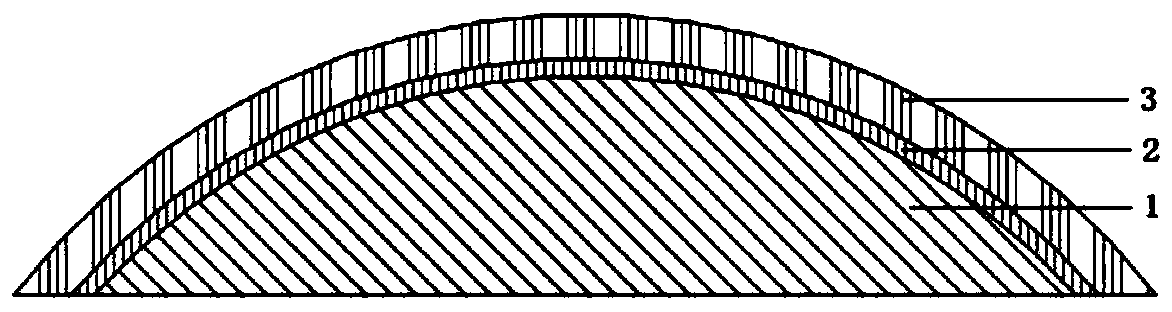

[0033] Step 1, using indium steel as the material, grinding and processing, and making a concave mirror mold 1 with a diameter of 200 mm, a radius of curvature of 700 mm, and a surface shape of λ / 50 (λ=10.6 μm);

[0034] Step 2: Electroplate a silver layer 2 on the surface of the mold 1 with a thickness of 80 μm by using a coating process;

[0035] Step 3, using tools such as sandpaper that can increase the surface roughness, treat the side of the silver layer 2 that is not combined with the mold 1, so that the surface is completely roughened;

[0036] Step 4. According to the layup design and layup process requirements, the carbon fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com