Antioxidative edible oil gel and preparation method thereof

An oil gel, anti-oxidation technology, applied in the field of edible oil, to achieve the effect of improving stability and water dispersibility, high stability, and keeping oil stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Mix 50g of policosanol, including 1% tetracosanol, 25% hexacosanol, 2% heptacosanol, 65% octacosanol, 2% nonacosanol , 1% triacontanol, 2% tricosanol and 2% tetracosanol, mixed with 1200g sunflower oil, and stirred at a rate of 200r / min for 0.3 hours at 100°C;

[0035] 2) Cool the mixture in step 1) to 0°C at a cooling rate of -1°C / min; during the cooling process, add 130 mL of whey protein isolate solution with a concentration of 10% (m / v) and a pH of 2.1 Add to the mixture and stir to combine;

[0036] 3) The mixture prepared in step 3) was vacuum freeze-dried and placed at 15°C for 3 days.

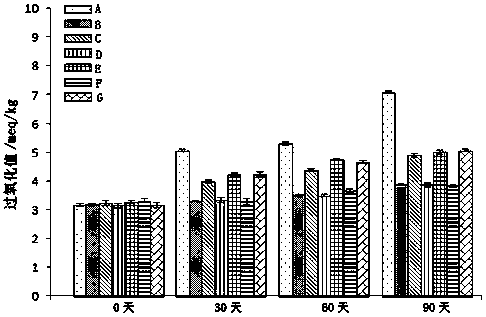

[0037] Depend on figure 1 From graphs B and C, it can be seen that as time goes on, the oxidation rate of policosanol-sunflower oil-whey protein isolate oleogel is significantly faster than that of policosanol-sunflower oil oleogel and sunflower seed oil. Oil is slower, indicating that policosanol-sunflower oil-whey protein isolate oil gel has a certain antioxidant effect a...

Embodiment 2

[0040] 1) 40g policosanol, including 1% tetracosanol, 20% hexacosanol, 2% heptacosanol, 70% octacosanol, 2% nonacosanol , 1% triacontanol, 2% tricosanol and 2% tetracosanol, mixed with 1000g linseed oil, and stirred at a speed of 300r / min for 0.5 hours at 110°C;

[0041] 2) Cool the mixture in step 1) to 1°C at a cooling rate of -2°C / min; during the cooling process, add 130 mL of peanut protein solution with a concentration of 20% (m / v) and a pH of 2.6 to the mixture in, and stir to mix;

[0042] 3) Dry the mixture prepared in step 2) with electric blast and place it at 20°C for 4 days.

[0043] Depend on figure 1 It can be seen from D and E graphs that as time goes on, the oxidation rate of policosanol-linseed oil-peanut protein oleogel is significantly faster than that of policosanol-linseed oil oleogel and sunflower oil. slow, indicating that policosanol-linseed oil-peanut protein oil gel has a certain antioxidant effect and can be stored for a long time.

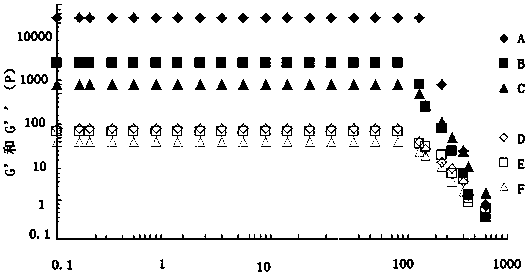

[0044] Depend ...

Embodiment 3

[0046] 1) Mix 50g of policosanol, including 2% tetracosanol, 26% hexacosanol, 2% heptacosanol, 61% octacosanol, 2% nonacosanol , 2% triacontanol, 3% tricosanol and 2% tetracosanol, mixed with 1300g sesame oil, and stirred at a speed of 26r / min for 0.6 hours at 115°C;

[0047] 2) Cool the mixture in step 1) to 3°C at a cooling rate of -4°C / min; during the cooling process, 130 mL of α-casein solution with a concentration of 30% (m / v) and a pH of 2.2 Add to the mixture and stir to combine;

[0048] 3) The mixture prepared in step 2) was dried by electric blast and placed at 23°C for 3 days.

[0049] Depend on figure 1 From graphs F and G in middle, it can be seen that as time goes on, the oxidation rate of policosanol-sesame oil-α-casein oleogel is significantly slower than that of policosanol-sesame oil oleogel and sunflower oil, It shows that policosanol-sesame oil-α-casein oil gel has a certain antioxidant effect and can be stored for a long time.

[0050] Depend on figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com