Surface rubidium-doped titanium material as well as preparation method and application thereof

A rubidium salt and reaction technology, which is applied in the surface rubidium-doped titanium material and its preparation field, can solve the problems of high postoperative infection rate, lack of local bone tissue integration, insufficient antibacterial performance of titanium surface, etc., and achieve wide application prospects and good Anti-Staphylococcus aureus, the effect of solving wound infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Use 400-mesh, 600-mesh, 800-mesh, 1200-mesh sandpaper to polish the pure titanium material until the surface is smooth without scratches, then use ethanol, acetone, and deionized water to perform ultrasonic cleaning, dry and blow dry; the diameter of the pure titanium material is 14.5mm round titanium material with a thickness of 1mm is soaked in 5ml 5M sodium hydroxide solution for alkali heat treatment, the treatment temperature is 55°C, and the time is 24h; use deionized water to ultrasonically clean the titanium material after alkali heat treatment to neutral , dry and blow dry; soak the surface-dried and alkali heat-treated titanium material in 1M rubidium chloride solution for rubidium alkali heat treatment, the treatment temperature is 55°C, and the time is 12h; finally, the above-mentioned alkali heat treated and rubidium alkali heat treated The titanium material is calcined at high temperature at a temperature of 550°C, the heating rate is 5°C / min, and the time ...

Embodiment 2

[0064] Polish the Ti-6Al-4V titanium material with 400 mesh, 600 mesh, 800 mesh, and 1200 mesh sandpaper until the surface is smooth without scratches, and then use ethanol, acetone, and deionized water to perform ultrasonic cleaning and dry it; Soak a titanium alloy sheet with a thickness of 1 mm in 5ml of 5M potassium hydroxide solution for alkali heat treatment at a temperature of 65°C for 18 hours; use deionized water to ultrasonically clean the titanium material after alkali heat treatment, and dry it; The dried and alkali-heat treated titanium material is soaked in 2.5M rubidium nitrate solution for rubidium alkali heat treatment, the treatment temperature is 65°C, and the time is 18h; finally, the above-mentioned titanium material that has been subjected to alkali heat treatment and rubidium alkali heat treatment is calcined at high temperature, calcined The temperature is 650°C, the heating rate is 5°C / min, and the time is 18h, and the furnace is air-cooled to obtain th...

Embodiment 3

[0089] Polish the Ti-6Al-4V titanium material with 400 mesh, 600 mesh, 800 mesh, and 1200 mesh sandpaper until the surface is smooth without scratches, and then use ethanol, acetone, and deionized water to perform ultrasonic cleaning and dry it; The titanium alloy sheet with a thickness of 1 mm is soaked in 5ml of 5M strontium hydroxide solution for alkali heat treatment, the treatment temperature is 75 ° C, and the time is 24 hours; use deionized water to ultrasonically clean the titanium material after alkali heat treatment, and dry it; The dried and alkali-heat treated titanium material is soaked in 5M rubidium sulfate solution for rubidium alkali heat treatment. The treatment temperature is 75°C for 24 hours. The temperature is 700°C, the heating rate is 5°C / min, and the duration is 24h. Air-cooled with the furnace, and the surface rubidium-doped titanium material is obtained.

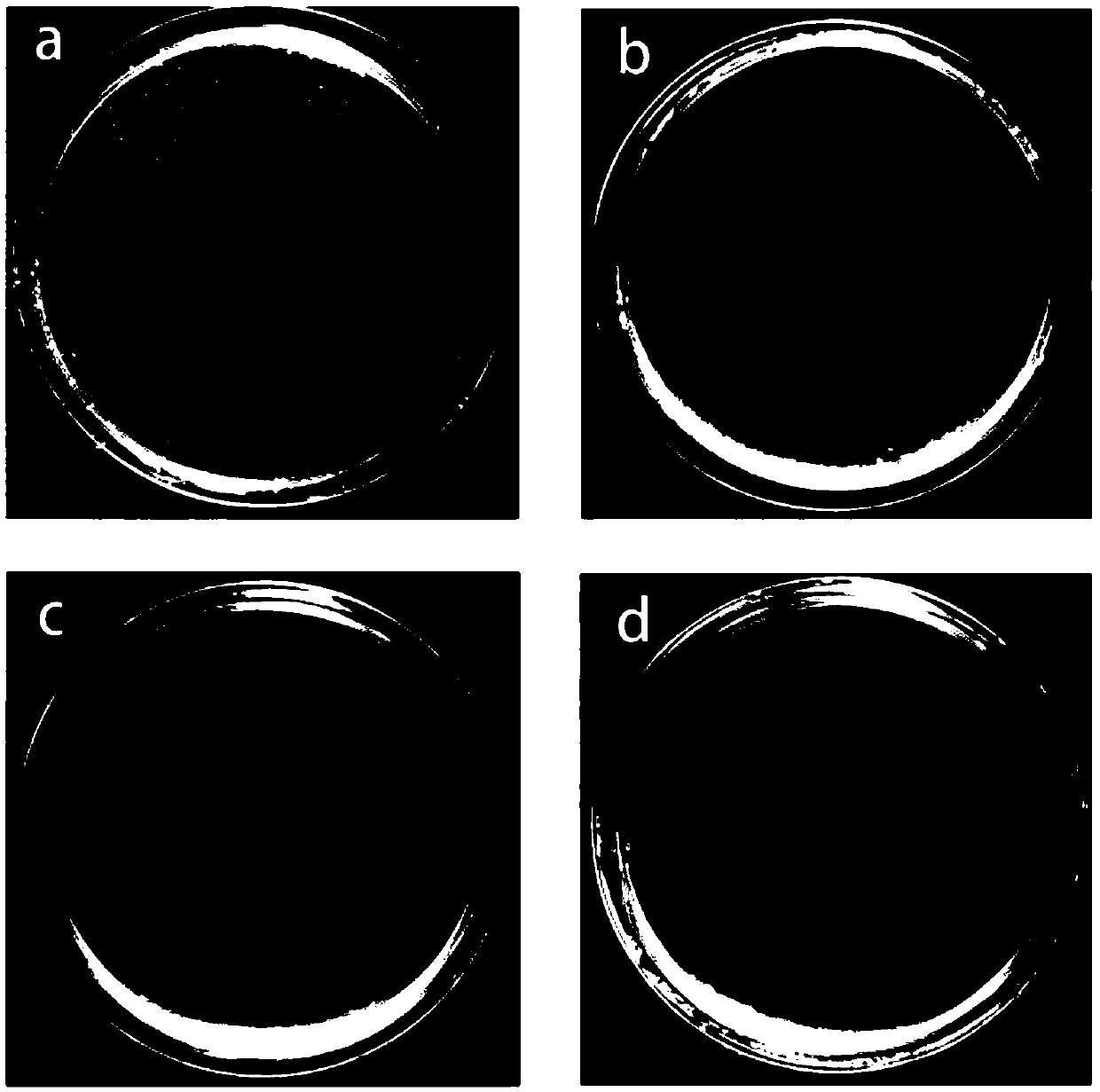

[0090] Figure 4 (a) is the XPS diagram of the surface-doped rubidium-titanium material obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com