Overall process method of Fenton-like air-flotation process

An overall process, Fenton's technology, applied in chemical instruments and methods, textile industry wastewater treatment, flotation water/sewage treatment, etc. The effect of increasing civil facilities, improving catalytic efficiency, and improving catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

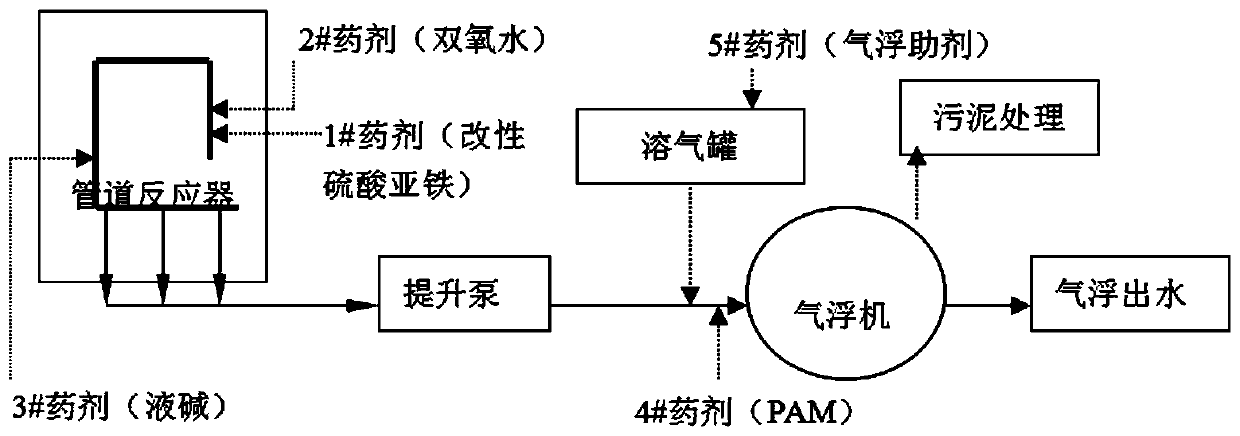

[0019] An overall process method similar to Fenton plus air flotation process, the whole process method is divided into two sections:

[0020] The first stage: complete the Fenton-like main reaction, oxidize and decompose organic pollutants in wastewater, set up a new type of pure fluid static pipeline reactor in the water absorption well or water collection well, and add Fenton-like chemicals and liquid caustic soda in the pipeline reactor, First, the Fenton-like chemicals are fully mixed and oxidized to decompose the organic pollutants in the printing and dyeing wastewater, and then the pH is adjusted by liquid alkali, and a large number of fine sludge particles are formed in the mixed solution. The main function is to degrade the organic pollutants and adjust the pH of the mixed solution to 6- 9. The main stage of reducing COD and chroma of printing and dyeing wastewater;

[0021] The second stage: complete the separation of mud and water, the mixed liquid after the Fenton-...

Embodiment 2

[0023] According to the overall process of the Fenton-like plus air flotation process described in Example 1, the Fenton-like agent is a combination of modified ferrous sulfate and hydrogen peroxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com