Microwave enhanced photocatalytic oxidation air conditioning system adopting in-situ synchronous regulation and control activated carbon fibers as carrier

An air conditioning system and activated carbon fiber technology, applied in the field of air conditioning systems, can solve the problems of low air purification quality and efficiency, easy to produce intermediate harmful by-products, and low effective reaction rate, so as to improve adsorption efficiency and reduce organic pollutants , the effect of prolonging the use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

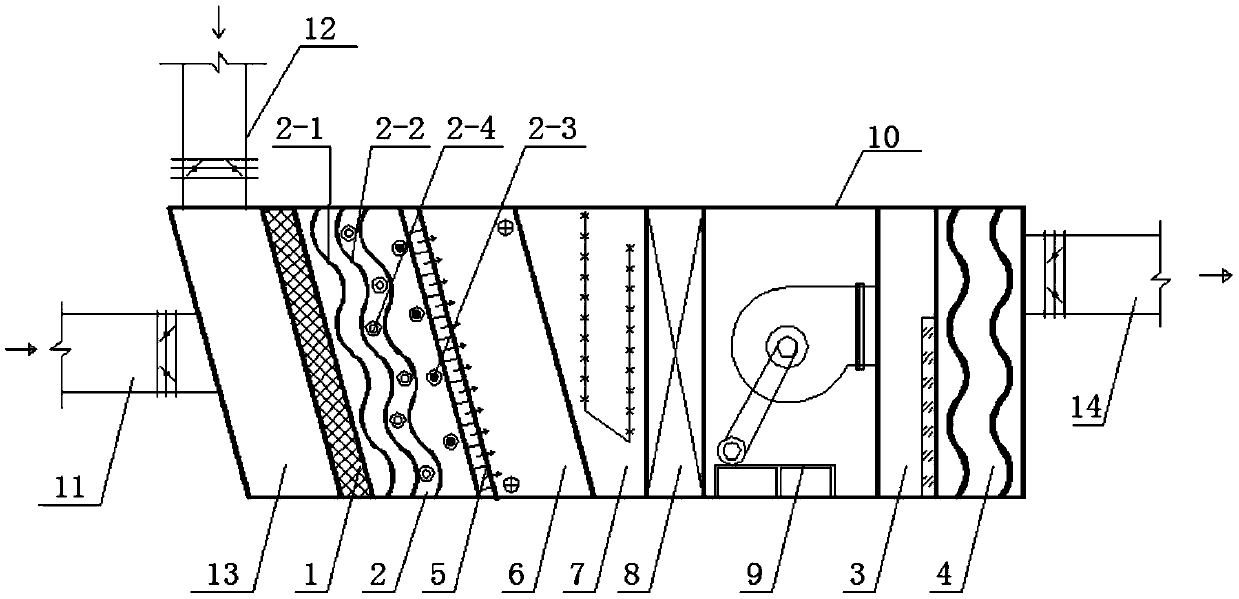

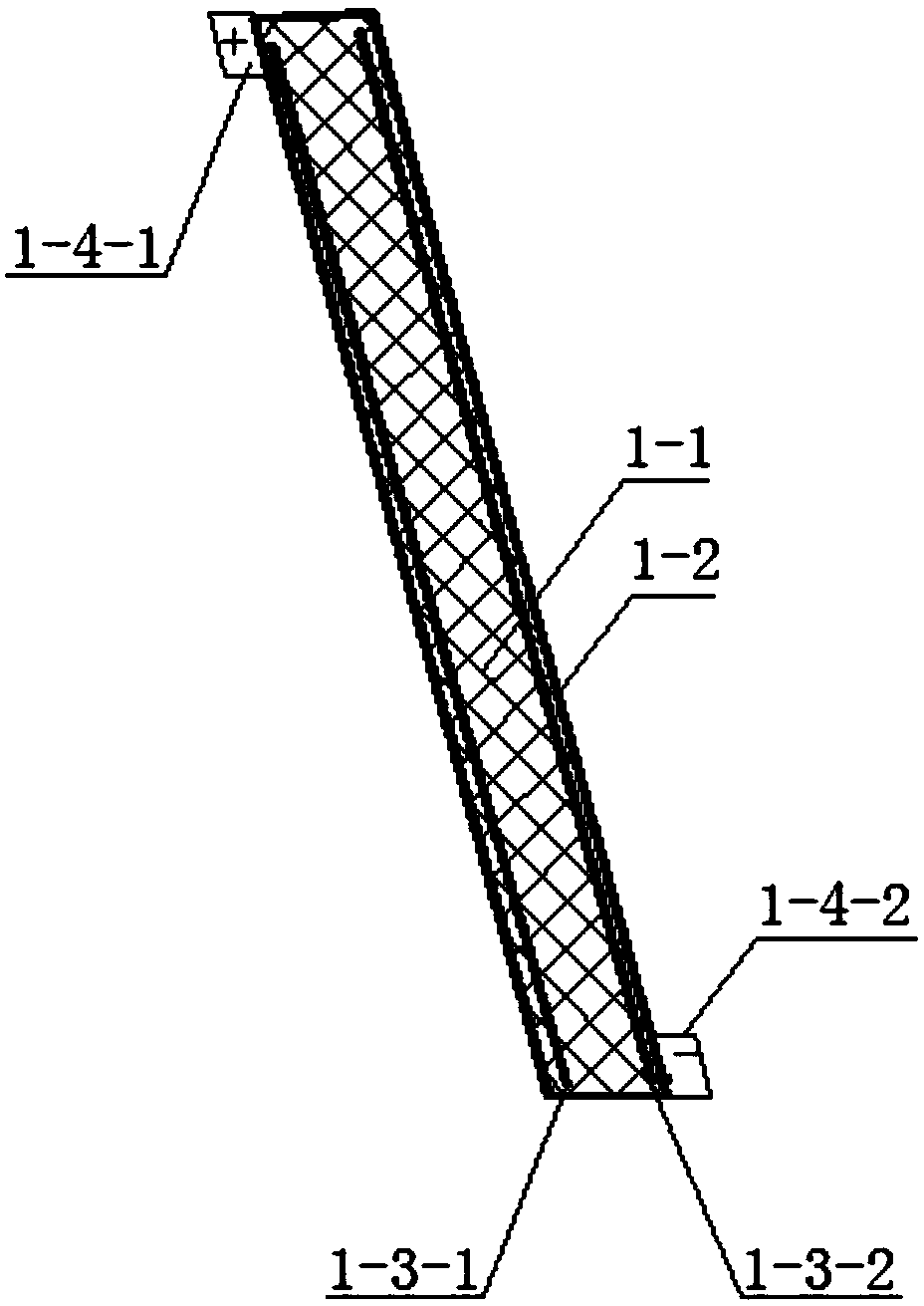

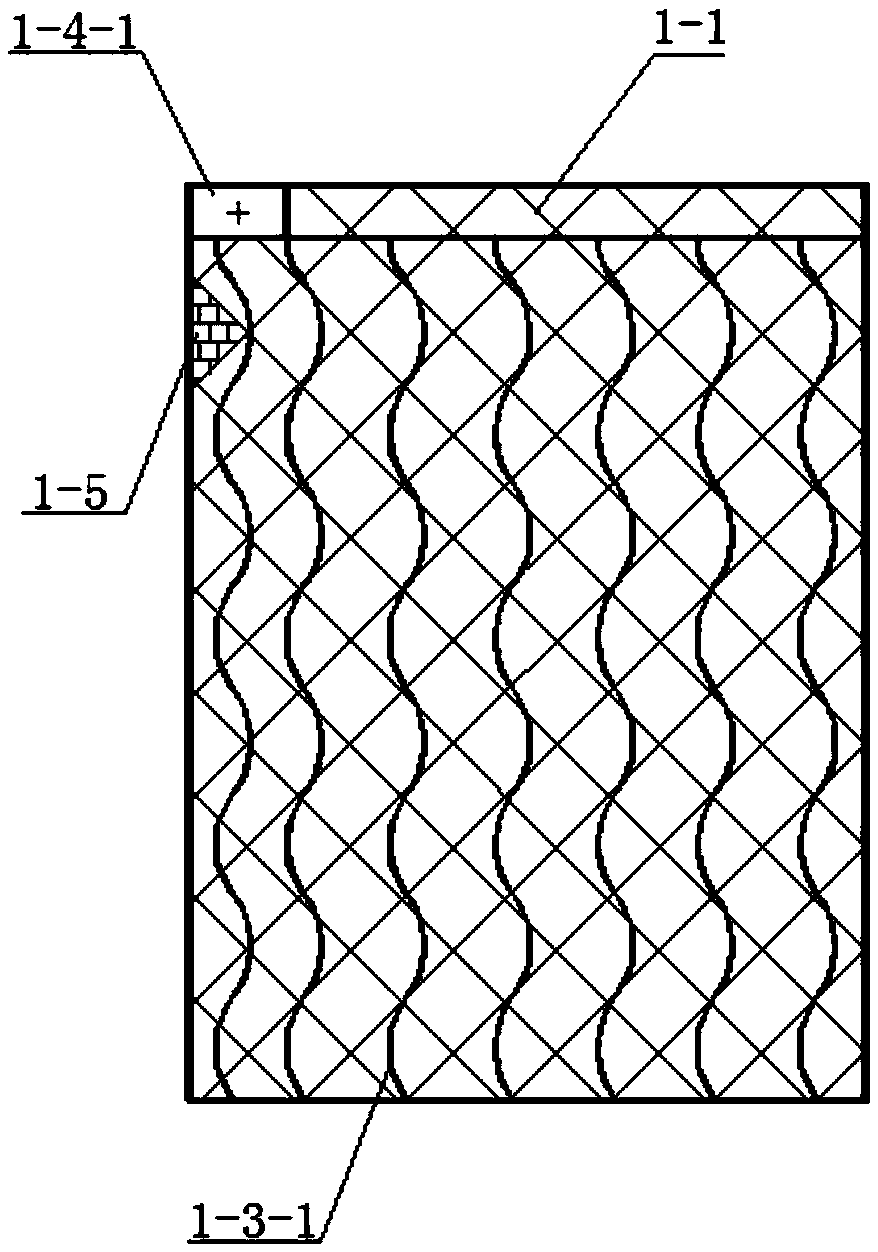

[0026] Specific implementation mode one: combine Figures 1 to 5 Describe this embodiment in detail. In this embodiment, a microwave-enhanced photocatalytic oxidation air-conditioning system with in-situ synchronous regulation of activated carbon fibers as a carrier includes an air intake section 13, a micro-electric field adsorption purification device 1, and a microwave-enhanced photocatalytic air purification system. Device 2, micro-ozone generating device 3, deep air purification device 4, preheating device 5, air cooler device 6, steam spray humidifying device 7, reheating device 8, blower device 9 and housing 10;

[0027] Along the wind flow direction, the housing 10 is sequentially provided with an air intake section 13, a micro-electric field adsorption purification device 1, a microwave-enhanced photocatalytic air purification device 2, a preheating device 5, an air cooler device 6, a steam spray humidification device 7, and then Heater 8, blower device 9, micro-ozone g...

specific Embodiment approach 2

[0062] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the described honeycomb adsorption material 1-5 obtains after filter material pretreatment; Described filter material is activated carbon, zeolite and bamboo charcoal particle One or a mixture of several of them; the particle size of the filter material is 4 mesh to 10 mesh. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0063] Specific embodiment three: the difference between this embodiment and one of the specific embodiments one or two is that: the filter material pretreatment is carried out according to the following steps: the filter material is soaked in 2% to 5% of the mass percentage Soak in hydrochloric acid, rinse after soaking for 2h-3h, then soak the filter material soaked in hydrochloric acid in water, boil for 20min-30min, and finally dry it. Others are the same as in the first or second embodiment.

[0064] In this specific embodiment, the pretreatment of the filter material can remove the impurities of the filter material itself, and it is easier to absorb 10 μm-100 μm large particles of dust and organic matter in the air.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Mesopore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com