Device and method for deep treatment of petrochemical wastewater secondary biochemical effluent

A technology for secondary biochemical effluent and petrochemical wastewater, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problem of low utilization rate of direct ozone oxidation, high substrate selectivity and energy consumption, and reaction speed. Slow and other problems, to achieve the effect of reducing investment and operation costs, reducing organic pollutants, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

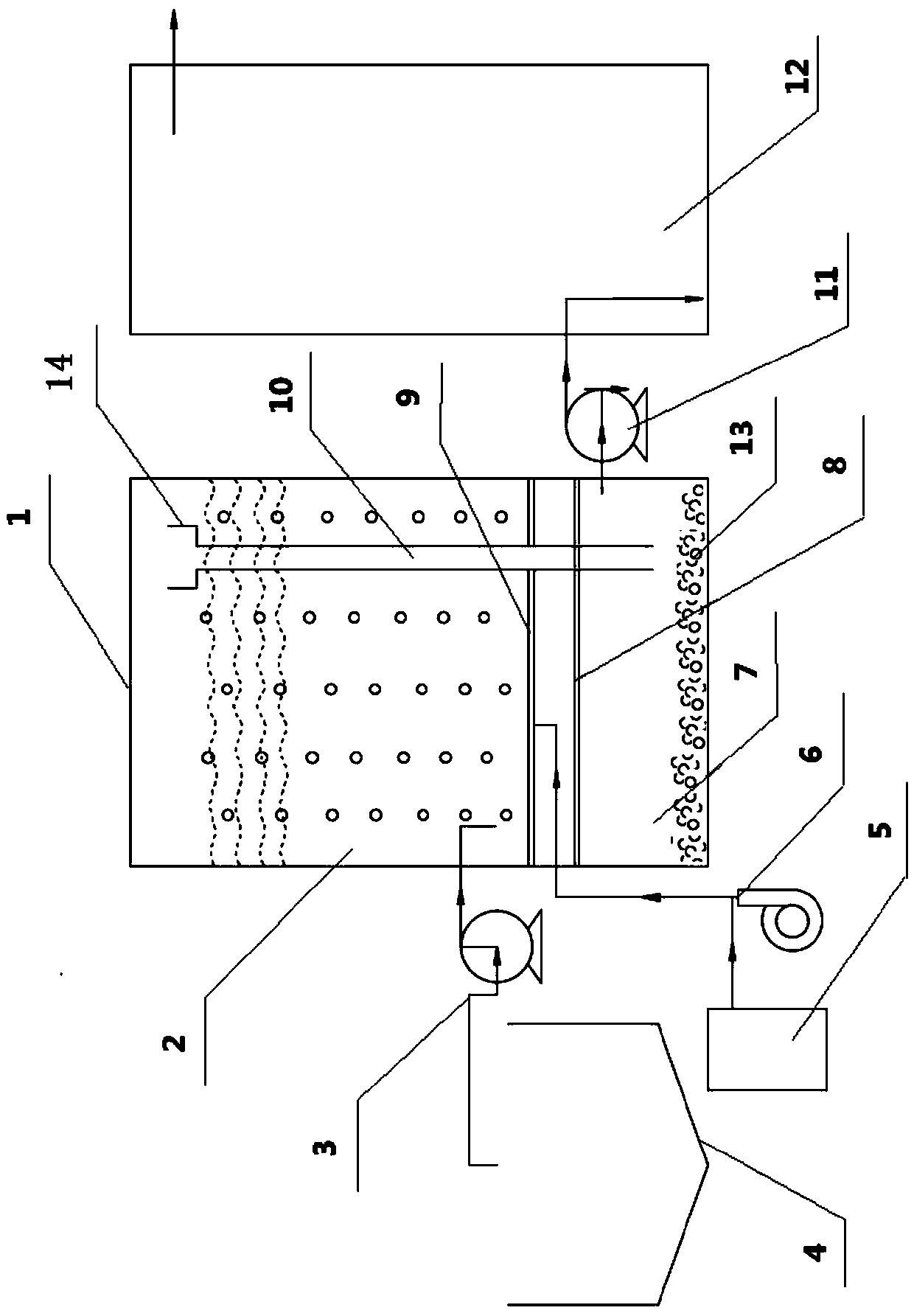

[0026] Embodiment 1, with reference to figure 1 , a treatment device for advanced treatment of petrochemical wastewater secondary biochemical effluent: the device includes a decomposition tank 1, and the decomposition tank 1 is equipped with a decomposition tank 1 divided into an upper ozone catalytic oxidation zone 2 and a lower ozone tail gas decomposition zone 7. The ozone catalytic oxidation zone 2 is connected to the waste water secondary sedimentation tank 4 through the water inlet pipeline 3, and the overflow pipe 10 leading from the upper part of the ozone catalytic oxidation zone 2 to the ozone tail gas decomposition zone 7 is arranged in the decomposition tank 1, and the ozone tail gas is decomposed The bottom of zone 7 is provided with manganese sand or ceramic packing 13, the ozone tail gas decomposition zone 7 is provided with a water outlet pipeline 11, and the bottom of the ozone catalytic oxidation zone 2 is fixed with an ozone aerator 9, and the ozone aerator 9...

Embodiment 2

[0028] Embodiment 2, with reference to figure 1 , a treatment device for advanced treatment of petrochemical wastewater secondary biochemical effluent: the volume ratio of the ozone catalytic oxidation zone to the ozone tail gas decomposition zone is 3:1; the top of the overflow pipe 10 is connected to the overflow pipe 10 The overflow tank 14. The filling ratio of the manganese sand or ceramic filler in the ozone tail gas decomposition zone is 10%; the filled manganese sand or ceramic filler is preferably an ozone decomposing agent filler whose active components are palladium and cesium. All the other are identical with embodiment 1.

Embodiment 3

[0029] Example 3, a method for advanced treatment of secondary biochemical effluent of petrochemical wastewater, using the treatment device for advanced treatment of secondary biochemical effluent of petrochemical wastewater described in Example 1, the steps are as follows:

[0030] (1) Ozone catalytic oxidation: The effluent from the secondary sedimentation tank of petrochemical wastewater enters the ozone catalytic oxidation zone through the water inlet pipeline for ozone catalytic oxidation treatment. During the treatment, ozone catalytic oxidant is added to improve the biodegradability of wastewater; the water in the ozone catalytic oxidation zone continues to rise After high, it enters the overflow pipe, and enters the ozone tail gas decomposition area through the overflow pipe;

[0031] (2) Ozone tail gas removal: The wastewater entering the ozone tail gas decomposition zone is decomposed in the ozone tail gas decomposition zone, and is filtered and decomposed by filler m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com