Preparation method and light-emitting device of modified metal chalcogenide

A metal sulfur compound technology, applied in the preparation method of modified metal chalcogenides and the field of light-emitting devices, can solve the problems of poor hole transport ability, achieve high charge transport efficiency, low cost, and realize the effect of large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

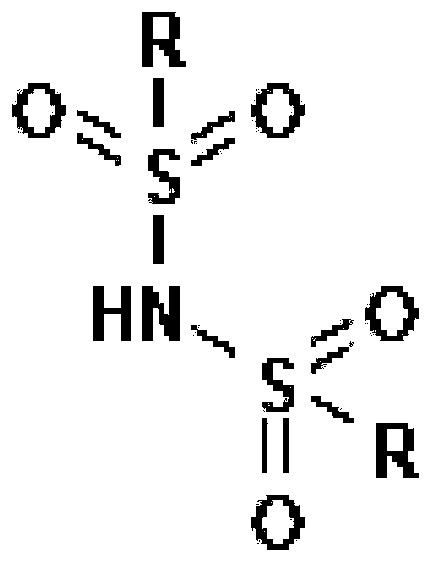

[0016] The embodiment of the present invention provides a preparation method of a modified metal chalcogenide. This preparation method comprises the steps:

[0017] Step S11: providing a metal chalcogenide, and placing the metal chalcogenide in a reaction chamber.

[0018] In the embodiment of the present invention, the chemical formula of the metal chalcogenide is generally MS 2 , where M is a metal element, such as Mo, W, V, Nb, Ta, etc., and S represents chalcogen elements such as S and Se. The prepared metal chalcogenides are placed in a reaction chamber for processing, and the reaction chamber is a device that can be ventilated and can be sealed.

[0019] Step S12: Passing in a non-oxidizing acid to perform a first modification treatment on the metal chalcogenide.

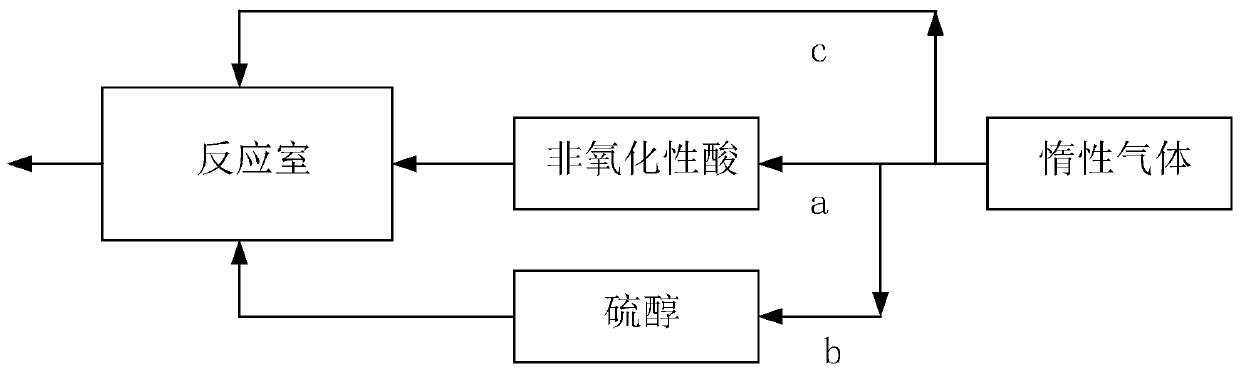

[0020] In an embodiment of the present invention, feeding the non-oxidizing acid includes: feeding an inert gas into the non-oxidizing acid solution, and letting the inert gas flow into the reaction chamber...

Embodiment 1

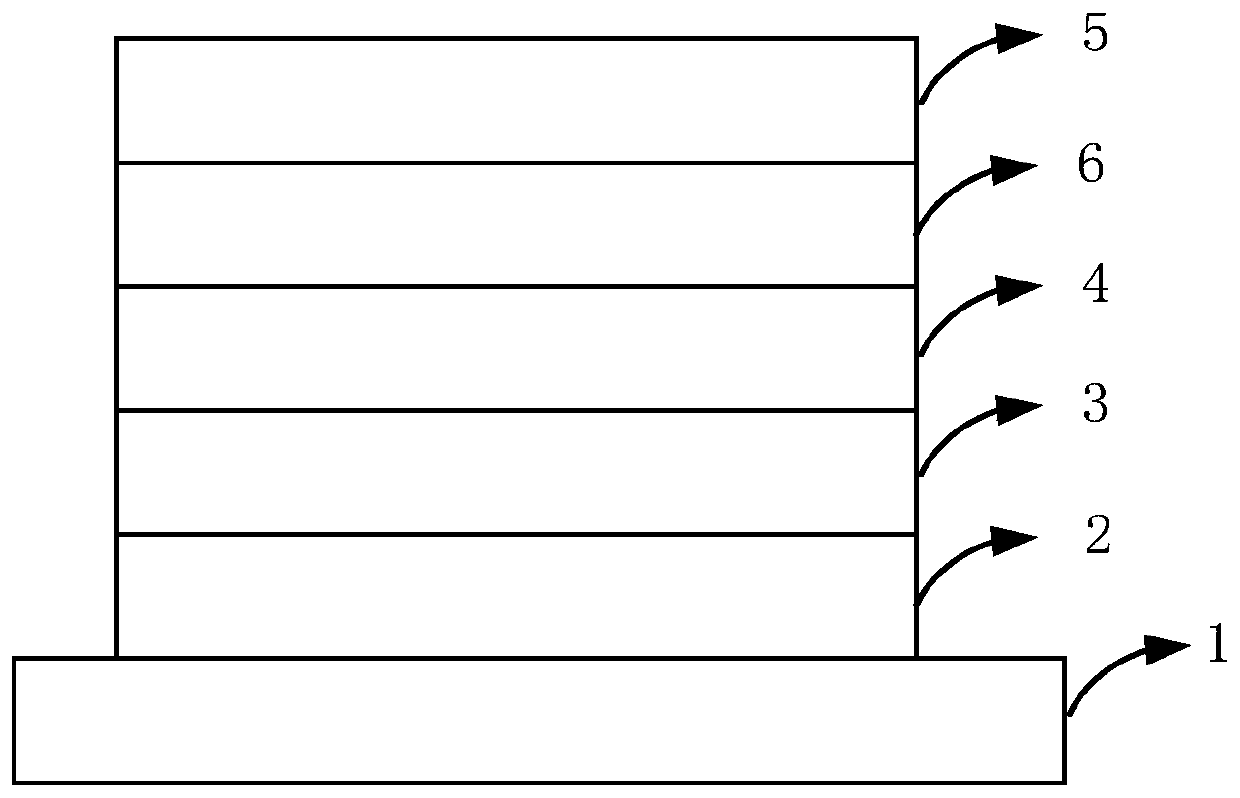

[0052] (1) Deposit a layer of MoS on a substrate containing silver nanowires 2 , by spin coating (NH 4 ) 2 MoS 4 aqueous solution and then heated and annealed to obtain MoS 2 Thin film (wherein, the heating condition is: 80°C / 15min in air, and the annealing condition is: inert gas annealing 300°C / 15min);

[0053] (2) MoS 2 film into the figure 2 In the device, the first modification treatment and the second modification treatment are carried out. Firstly, the gas HI of path a is introduced, and after 15 minutes of ventilation, the path a is closed, and the inert gas is introduced through path c to increase the pressure, and the pressure is 5 MPa. After the pressure is lowered to normal pressure, the gas ethanedithiol is introduced into route b, and after ventilation for 15 minutes, an inert gas is introduced through route c to increase the pressure, and the pressure is 5MPa. After the pressure is reduced to normal pressure, move the substrate into the glove box, deposi...

Embodiment 2

[0058] (1) Deposit a layer of MoSe on the substrate containing FTO 2, the thickness of 20nm was prepared by CVD method, and then the MoSe 2 film into the image 3 The first modification treatment and the second modification treatment are carried out in the device. First pass the gas HBr into the a channel, and after 30 minutes of ventilation, close the a channel, and feed the inert gas through the c channel to increase the pressure, and the pressure is 5MPa. After the pressure is lowered to normal pressure, ethanedithiol is introduced into route b, and after ventilation for 15 minutes, an inert gas is introduced through route c to increase the pressure, and the pressure is 5MPa. After the pressure is reduced to normal pressure, the substrate is moved into the glove box, and then a layer of hole transport layer is deposited, which is TFB, which is spin-coated at a speed of 3000rpm, and then annealed at 150°C for 30min;

[0059] (2) Deposit a layer of light-emitting layer wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| carrier mobility | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com