A kind of extraction method of pineapple skin dregs soluble dietary fiber

A technology of dietary fiber and pineapple peel, which is applied in the extraction of soluble dietary fiber and soluble dietary fiber from pineapple peel, can solve the problems of lack of processing technology research, aggravate environmental pollution, and discard the peel, and achieve the extraction process operation Simple, good physical and chemical function, high extraction rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

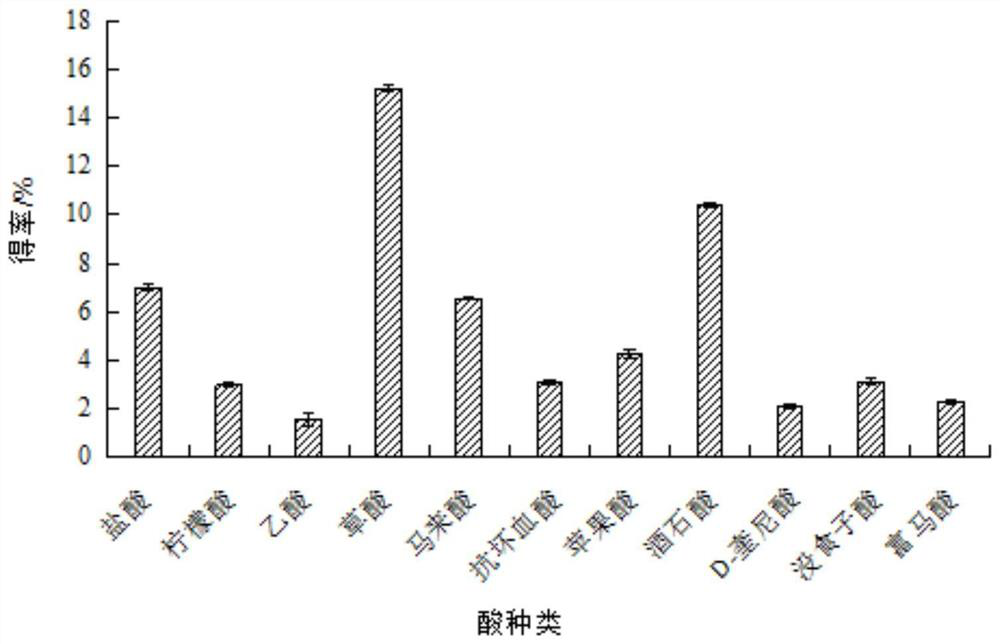

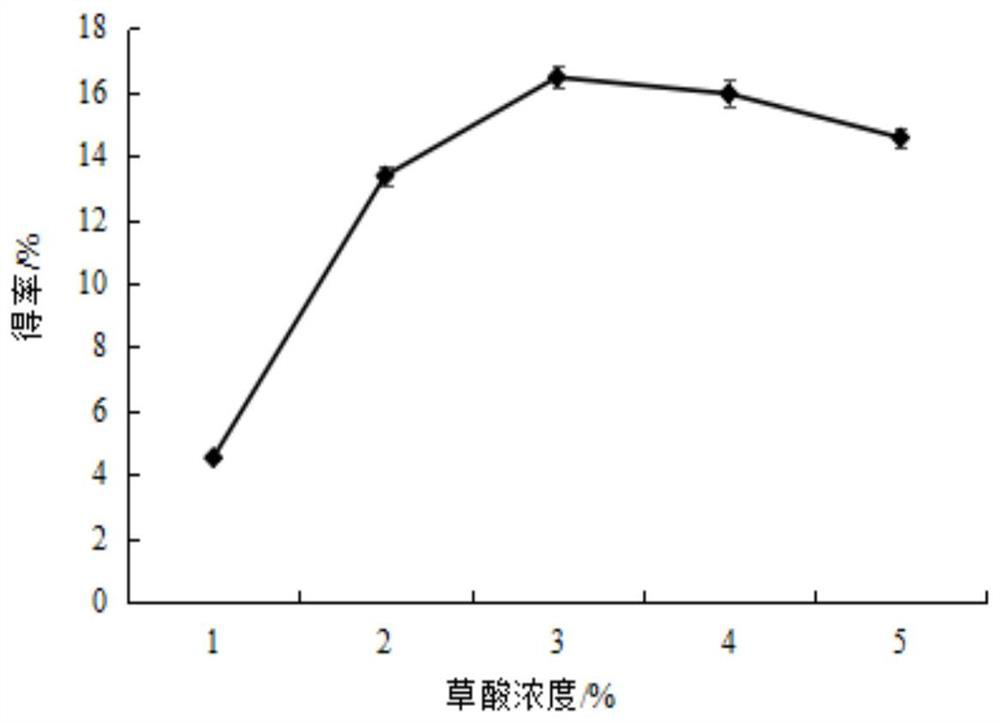

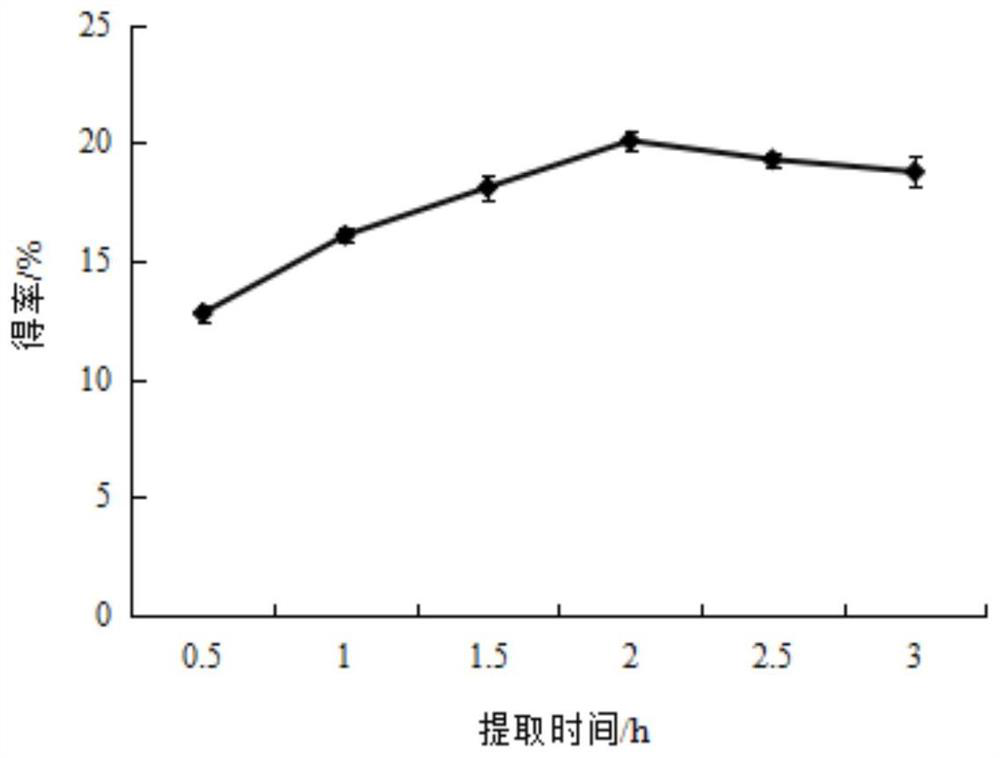

Method used

Image

Examples

Embodiment 1

[0031] A method for extracting soluble dietary fiber from pineapple pomace, comprising the following steps:

[0032] (1) Degreasing: Screen and clean the pineapple pomace discarded in fruit juice processing, blanch in hot water at 85°C for 3 minutes, then dry with hot air at 45°C for 48 hours; pass through a 40-mesh sieve after crushing, and use a material-to-liquid ratio of 1:5 (m / v) Add petroleum ether, stir and soak at room temperature for 1 hour, filter with suction, and air-dry to obtain the degreased material;

[0033] (2) Double-enzyme hydrolysis: add distilled water to the degreased material prepared in step (1) at a material-to-liquid ratio of 1:30 (m / v), adjust the pH value of the material liquid to 6.0, and add 1% of the weight of the degreased material α-Amylase, in a water bath at 50°C for 60 minutes, after cooling to 40°C, add papain with a weight of 0.1% of the weight of the degreased material, and bathe in water for 60 minutes; keep stirring during the period, ...

Embodiment 2

[0038] A method for extracting soluble dietary fiber from pineapple pomace, comprising the following steps:

[0039] (1) Degreasing: Screen and clean the pineapple pomace discarded in fruit juice processing, blanch in hot water at 90°C for 3 minutes, then dry with hot air at 50°C for 40 hours; pass through a 60-mesh sieve after crushing, and use a material-to-liquid ratio of 1:6 (m / v) Add petroleum ether, stir and soak at room temperature for 3 hours, filter with suction, and air-dry to obtain the degreased material;

[0040] (2) Double-enzyme hydrolysis: add distilled water to the degreased material prepared in step (1) at a material-liquid ratio of 1:30 (m / v), adjust the pH value of the material liquid to 7.5, and then add 2.5% of the weight of the degreased material α-amylase in a water bath at 75°C for 20 minutes, after cooling to 60°C, add papain with a weight of 0.3% of the weight of the degreased material, and bathe in water for 20 minutes; keep stirring during the period...

Embodiment 3

[0045] A method for extracting soluble dietary fiber from pineapple pomace, comprising the following steps:

[0046] (1) Degreasing: Screen and clean the pineapple pomace discarded in fruit juice processing, blanch in hot water at 90°C for 2 minutes, and dry with hot air at 55°C for 48 hours; crush and pass through an 80-mesh sieve with a material-to-liquid ratio of 1:3 (m / v) Add petroleum ether, stir and soak at room temperature for 4 hours, filter with suction, and air-dry to obtain the degreased material;

[0047] (2) Double-enzyme hydrolysis: Add 40 times the weight of distilled water to the degreased material prepared in step (1), adjust the pH value of the material solution to 6.5, add 3% α-amylase by weight of the degreased material, and bathe in water at 65°C for 40 minutes , after cooling to 55°C, add papain with 0.2% of the weight of the degreased material, and bathe in water for 30 minutes; stir continuously during the period, heat to 95°C for 5 minutes to kill the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com