A kind of separation method of active ingredient of Oryx sativa

A technology of active ingredients and separation methods, which is applied in the field of efficient separation of active ingredients of Rubescens japonicus, can solve the problems of difficult regeneration of activated carbon, poor decolorization effect, unsatisfactory effects, etc., to reduce the discharge of "three wastes" and reduce the content of impurities , The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

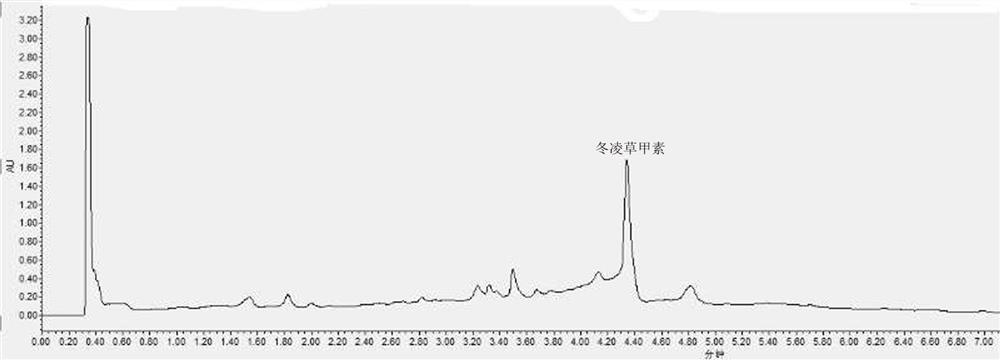

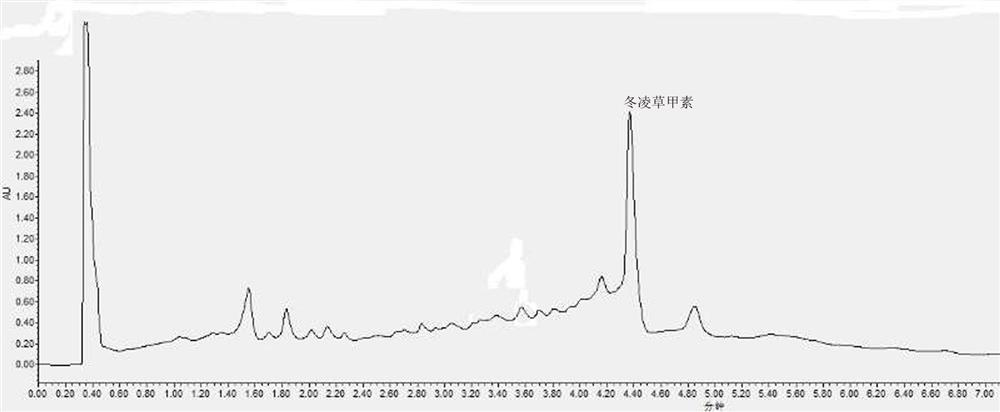

[0027] Get 1 kilogram of Rubescensia dry leaves and extract and concentrate with 95% ethanol to obtain 100 grams of Rubescens oriolis extract, wherein the content of Rubescensin A is 3.24%. The liquid chromatogram of the extract is shown in figure 1 .

[0028] Weigh 50 g of the concentrated Oryx sativa extract and put it into a supercritical extraction kettle, fix the MILLPORE Ultracel3KDa ultrafiltration membrane on the lower part of the barrel, put it into the separation kettle Ⅰ, and then flush it into the supercritical CO 2 The fluid is pressurized and circulated, the extraction pressure is 10MPa, the temperature is 40°C, the pressure of the separation tank I is 9 MPa, the temperature is 35°C, the pressure of the separation tank II is 3MPa, the temperature is 40°C, and the fluid flow rate is 5L h -1 , the extraction time was 0.5 hours. After treatment, the color of Rubescensia extract changed from dark brown-green to orange-red, the content of impurities such as pigments ...

Embodiment 2

[0030] Take 1 kg of dried leaves of Rubescens oriolis and extract and concentrate with 95% ethanol to obtain 100 grams of Rubescens oriolis extract, in which the content of Rubescensin A is 3.24%.

[0031] Weigh 50 g of the concentrated Oryx sativa extract and put it into a supercritical extraction kettle, fix the Miilipore 3KD ultrafiltration membrane on the lower part of the barrel, put it into the separation kettle I, and then flush it into the supercritical CO 2 The fluid is pressurized and circulated, the extraction pressure is 20MPa, the temperature is 50°C, the pressure of the separation tank I is 19MPa, the temperature is 45°C, the pressure of the separation tank II is 4MPa, the temperature is 35°C, and the fluid flow rate is 10L h -1 , and the extraction time was 1 hour. After treatment, the color of Rubescensia extract changed from dark brown-green to orange-red, the content of impurities such as pigments in Rubescens oriolis extract decreased, and the content of Rub...

Embodiment 3

[0033] Take 1 kg of dried leaves of Rubescens oriolis and extract and concentrate with 95% ethanol to obtain 100 grams of Rubescens oriolis extract, in which the content of Rubescensin A is 3.24%.

[0034] Weigh 50 g of the concentrated Oryx sativa extract and put it into a supercritical extraction kettle, fix the MILLPORE Ultracel3KDa ultrafiltration membrane on the lower part of the barrel, put it into the separation kettle Ⅰ, and then flush it into the supercritical CO 2 The fluid is pressurized and circulated, the extraction pressure is 15MPa, the temperature is 55°C, the pressure of the separation tank I is 14 MPa, the temperature is 40°C, the pressure of the separation tank II is 3MPa, the temperature is 35°C, and the fluid flow rate is 7L·h -1 , and the extraction time was 2 hours. After treatment, the color of Rubescensia extract changed from dark brown-green to orange-red, the content of impurities such as pigments in the extract of Rubescens oriolis decreased, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com