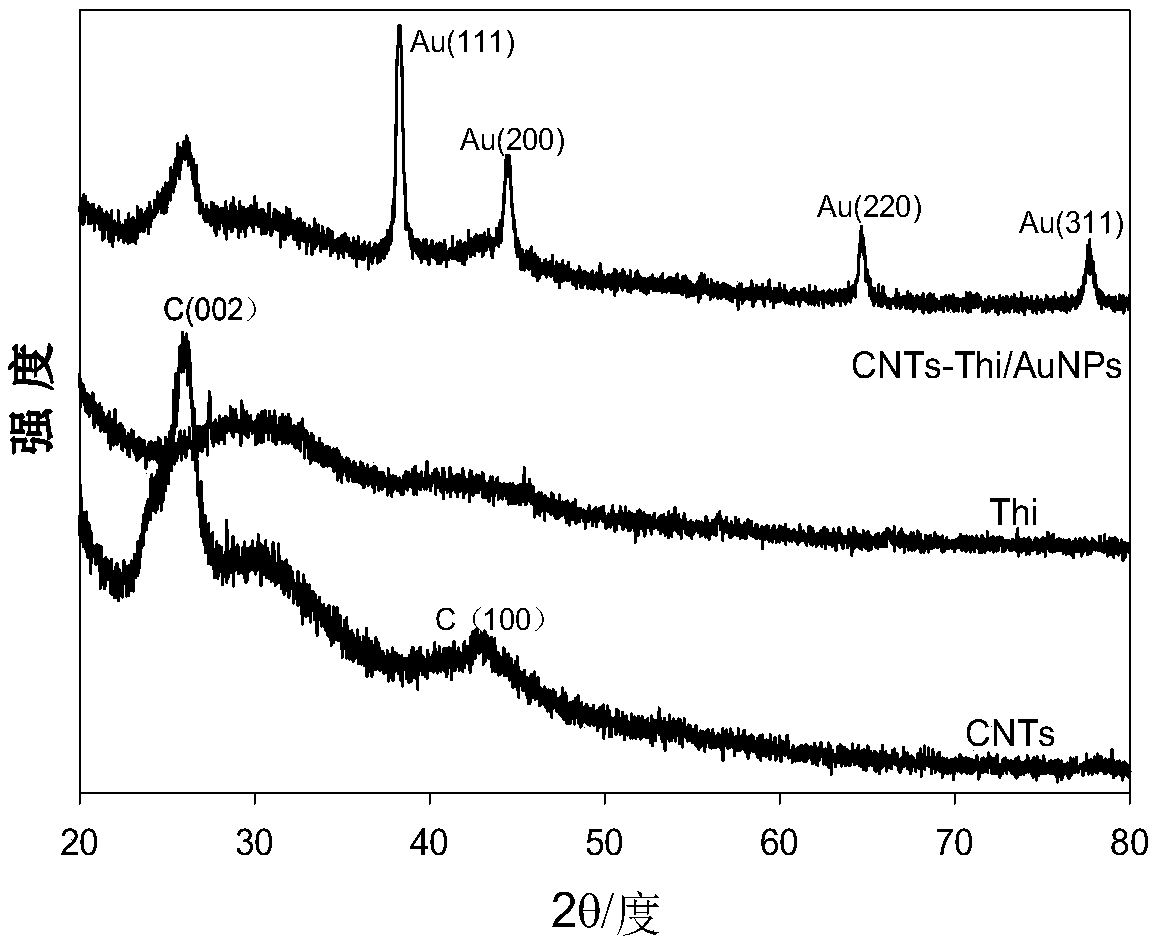

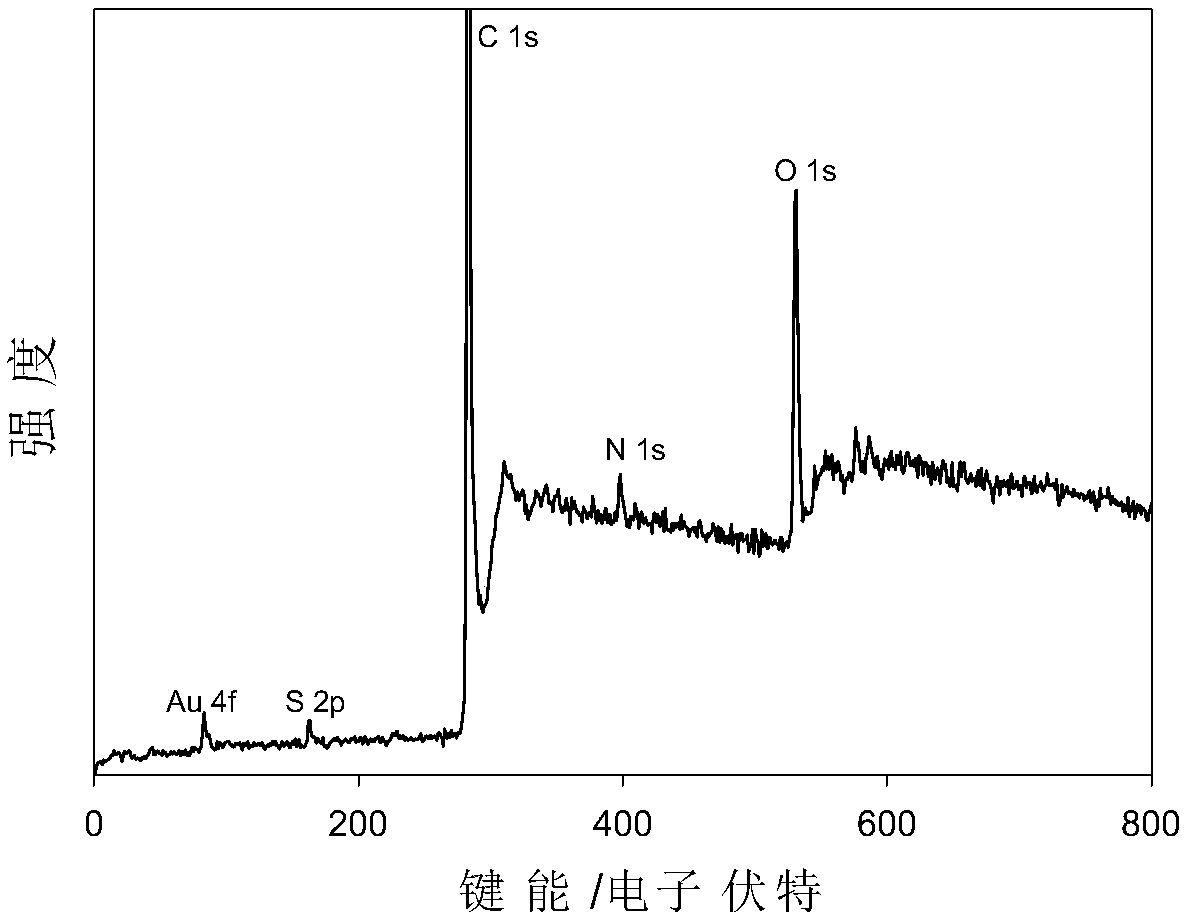

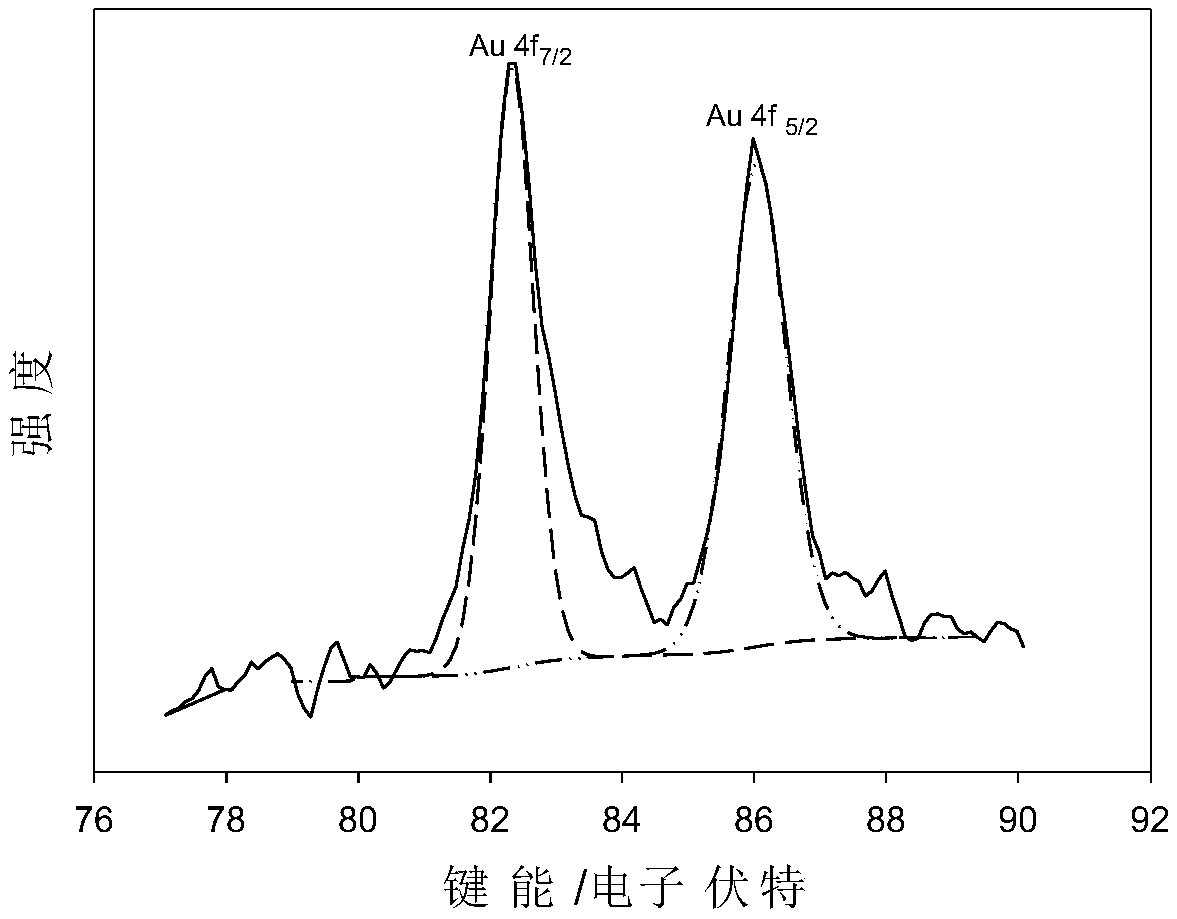

Carbon nanotube-thionine/gold nanoparticle composite material and preparation method and application thereof

A technology of gold nanoparticles and carbon nanotubes, applied in the direction of nanotechnology, nanotechnology, analytical materials, etc., can solve the problem of auxiliary reducing agent and support matrix without any literature and patent reports, weak surface adhesion of carbon nanotubes, gold The problem of large particle size of nanoparticles can achieve the effect of simple method, strong adhesion ability and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] A preparation method of carbon nanotube-thionine / gold nanoparticle composite material, the method comprises the following steps:

[0070] (1) Acidification and cutting of carbon nanotubes: disperse 50mg of multi-walled carbon nanotubes in 50mL concentrated HNO at 1:3 3 (68%) and H 2 SO 4 (98%) mixture, sonicated in a 90°C water bath for 2 hours, after which, diluted with ice water to prevent further reaction; then the mixture was centrifuged, washed thoroughly with distilled water and repeated cycles until the pH value was about 7, centrifuged, and then at 70 Dry in an oven at ℃ for 18 hours;

[0071] (2) Preparation of carbon nanotube-thionine: dissolve 50mg of thionine in 20mL of 50°C hot water; then, add it to 20mL of the 2mg / mL carbon nanotube aqueous dispersion prepared in (1), And react at 30°C for 60 minutes; then, centrifuge at 12000rmp, wash the obtained sediment, centrifuge again, and finally dry in an oven at 70°C for 18 hours;

[0072] (3) Preparation of...

Embodiment 2

[0075] (1) Acidification and cutting of multi-walled carbon nanotubes: disperse 40 mg of multi-walled carbon nanotubes in 50 mL of concentrated HNO at 1:3 3 (68%) and H 2 SO 4 (98%) mixture, sonicate for 4 hours in a water bath at 80°C, after which, dilute with ice water to prevent further reaction; then centrifuge the mixture, wash thoroughly with distilled water and repeat the cycle until the pH value is about 7 (greater than 6), centrifuge Separating, and then drying the solid in an oven at 60°C for 24 hours to obtain pretreated carbon nanotubes;

[0076] (2) Preparation of carbon nanotube-thionine: dissolve 30mg of thionine in 20mL of 60°C hot water to obtain a thionine aqueous solution; subsequently, add the thionine aqueous solution to 20mL of the 2mg / mL prepared in step (1). carbon nanotube water dispersion, and reacted at 40°C for 30 minutes; then, centrifuged at 10,000rmp, washed the obtained sediment, centrifuged again, and finally dried in an oven at 60°C for 24 h...

Embodiment 3

[0080] Repeat embodiment 2, just stabilizer adopts citric acid, and reducing agent adopts the aqueous solution of sodium borohydride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com