Zinc-modified hierarchical pore ZSM-5 nano-zeolite and preparation method thereof

A technology of ZSM-5 and nano-zeolite, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of narrow channel structure, low product selectivity, easy deactivation, etc. To achieve the effect of increasing selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of SiO 2 / Al 2 o 3 ZSM-5 nanometer zeolite of 120:

[0036] ① Mix 66.67g of silica sol solution (30% by mass fraction), 17.78g of tetrapropylammonium bromide (TPABr) and 2.08g of seed crystal solution, stir at 35°C for 30 minutes, and define it as solution A;

[0037] ②Mix 1.354g of aluminum chloride hexahydrate with 45g of water, and define it as solution B;

[0038] ③ 30g ethylamine aqueous solution is defined as C solution;

[0039] ④ Add solution B to solution A dropwise, stir at 35°C for 90 minutes, then add solution C dropwise to the mixed solution, continue stirring at 35°C for 30 minutes, crystallize at 170°C for 72 hours, centrifuge, and dry at 80°C. Baking at 540°C.

[0040] Preparation of Zinc Modified ZSM-5 Nano Zeolite

[0041] ① Mix 5 g of the prepared ZSM-5 nano-zeolite with 150 ml of 0.2 mol / L sodium hydroxide aqueous solution, stir for 30 minutes at 80°C, centrifuge, and dry at 80°C.

[0042] ② Mix 0.37g of zinc nitrate hexahydrate wi...

Embodiment 2

[0050] Preparation of SiO 2 / Al 2 o 3 ZSM-5 nano zeolite of 160:

[0051] ① Mix 66.67g of silica sol solution (30% by mass fraction), 17.78g of tetrapropylammonium bromide (TPABr) and 2.08g of seed crystal solution, stir at 35°C for 30 minutes, and define it as solution A;

[0052] ② Mix 1.016g of aluminum chloride hexahydrate with 45g of water, and define it as solution B;

[0053] ③ 30g ethylamine aqueous solution is defined as C solution;

[0054] ④ Add solution B to solution A dropwise, stir at 35°C for 90 minutes, then add solution C dropwise to the mixed solution, continue stirring at 35°C for 30 minutes, crystallize at 170°C for 72 hours, centrifuge, and dry at 80°C. Baking at 540°C.

[0055] 5. Preparation of zinc-modified ZSM-5 nanometer zeolite Zn-2, same as in Example 1.

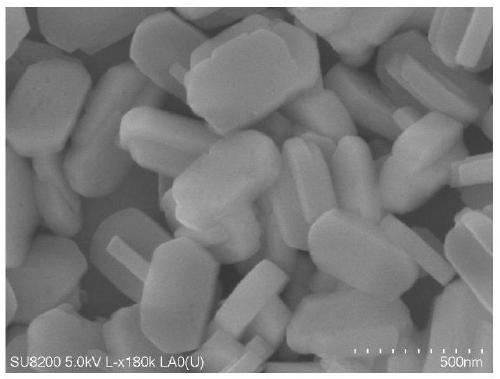

[0056] Figure 7 It is a TEM image of the zinc-modified ZSM-5 nano zeolite of Example 2 of the present invention. It can be seen from the figure that samples with different silicon-aluminu...

Embodiment 3

[0058] Preparation of SiO 2 / Al 2 o 3 ZSM-5 nano zeolite of 135:

[0059] ① Mix 66.67g of silica sol solution (30% by mass fraction), 17.78g of tetrapropylammonium bromide (TPABr) and 2.08g of seed crystal solution, stir at 35°C for 30 minutes, and define it as solution A;

[0060] ②Mix 0.813g of aluminum chloride hexahydrate with 45g of water, and define it as B solution;

[0061] ③ 30g ethylamine aqueous solution is defined as C solution;

[0062] ④ Add solution B to solution A dropwise, stir at 35°C for 90 minutes, then add solution C dropwise to the mixed solution, continue stirring at 35°C for 30 minutes, crystallize at 170°C for 72 hours, centrifuge, and dry at 80°C. Baking at 540°C.

[0063] The preparation of zinc-modified ZSM-5 nano zeolite Zn-3 is the same as in Example 1.

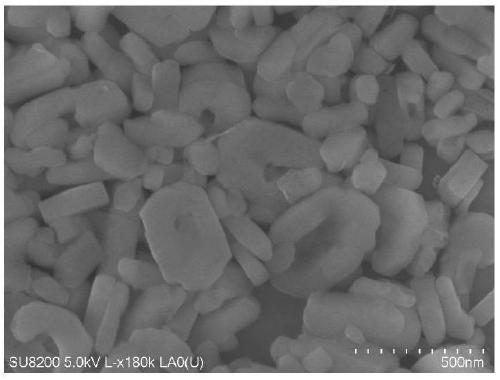

[0064] Figure 8 It is a TEM image of the zinc-modified ZSM-5 nano zeolite of Example 3 of the present invention. It can be seen from the figure that samples with different silicon-alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com