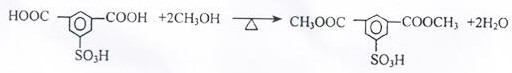

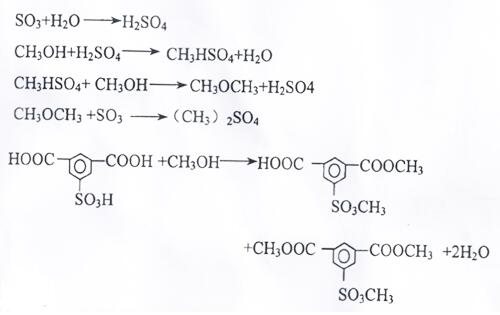

A production method for improving the yield and purity of dimethyl isophthalate-5-sulfonic acid for synthesizing three monomers

A technology of dimethyl isophthalate and isophthalic acid is applied in the synthesis field of intermediate dimethyl isophthalate-5-sulfonic acid, and can solve the problems of high reaction temperature, high content, low purity and the like , to reduce the consumption of methanol, improve the reaction speed, and improve the economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The weight of the sulfonated material used in this embodiment is 1670Kg, and the main component content (weight ratio) of the sulfonated material is as follows: isophthalic acid-5-sulfonic acid, 76.59%; isophthalic acid, 0.054%; sulfuric acid, 16.11%; SO 3 , 4.06%; the rest are sulfonated organic impurities and impurities brought in by raw materials.

[0057] 1. N 2 Gas purge

[0058] use N 2 The esterification kettle is purged with gas, and N 2 Adjust the pressure of the esterification kettle to 0.015 MPa to stop N 2 Through.

[0059] 2. Add sulfonated material

[0060] Add the sulfonated material to the esterification kettle.

[0061] 3. Add part of methanol

[0062] Put 700Kg of methanol into the methanol metering tank with a pump, and put 280Kg of methanol into the esterification kettle from the bottom of the esterification kettle with a plunger pump. After the methanol feeding is stopped, the agitator is turned by manual cranking, and then the motor switch ...

Embodiment 2

[0076] The weight of the sulfonated material used in this embodiment is 1675Kg, and the main component content (weight ratio) of the sulfonated material is as follows: isophthalic acid-5-sulfonic acid, 76.59%; isophthalic acid, 0.054%; sulfuric acid, 16.11%; SO 3 , 4.06%; the rest are sulfonated organic impurities and impurities brought in by raw materials. 1. N 2 Gas purge

[0077] use N 2 The esterification kettle is purged with gas until the pressure of the esterification kettle reaches 0.025 MPa to stop N 2 Through.

[0078] 2. Add sulfonated material

[0079] Add the sulfonated material to the esterification kettle.

[0080] 3. Add part of methanol

[0081] Use a pump to pump 735Kg methanol into the methanol metering tank, and use a plunger pump to pump 355Kg methanol into the esterification kettle from the bottom of the esterification kettle. After the methanol feeding is stopped, the agitator is turned by manual cranking, and then the motor switch of the agitator...

Embodiment 3

[0096] The weight of the sulfonated material used in this embodiment is 1680Kg, and the main component content (weight ratio) of the sulfonated material is as follows: isophthalic acid-5-sulfonic acid, 76.59%; isophthalic acid, 0.054%; sulfuric acid, 16.11%; SO 3 , 4.06%; the rest are sulfonated organic impurities and impurities brought in by raw materials. 1. N 2 Gas purge

[0097] use N 2 The esterification kettle is purged with gas until the pressure of the esterification kettle reaches 0.04 MPa to stop N 2 Through.

[0098] 2. Add sulfonated material

[0099] Add the sulfonated material to the esterification kettle.

[0100] 3. Add part of methanol

[0101] Put 760Kg of methanol into the methanol metering tank with a pump, and put 310Kg of methanol into the kettle from the bottom of the esterification kettle with a plunger pump. After the methanol feeding is stopped, the agitator is turned by manual cranking, and then the motor switch of the agitator is jogged, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com