Low-odor ABS material used for 3D printing and preparation method of low-odor ABS material

An ABS material and 3D printing technology, applied in the field of low-odor ABS material for 3D printing and its preparation, can solve the problems that it is difficult to fully compound the processing and use requirements of FDM3D printers, it is difficult to fully achieve the deodorization effect, and the adsorption capacity of the adsorbent is limited. Achieve the effect of low cost, easy operation, not easy to aggregate and decompose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

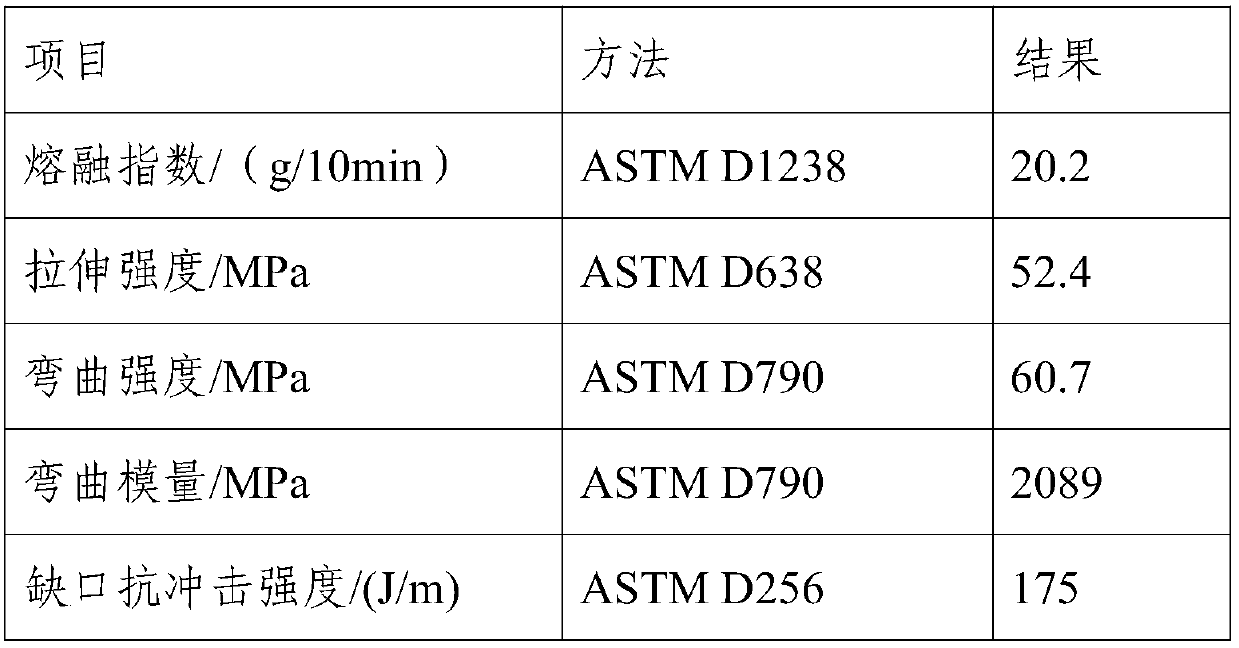

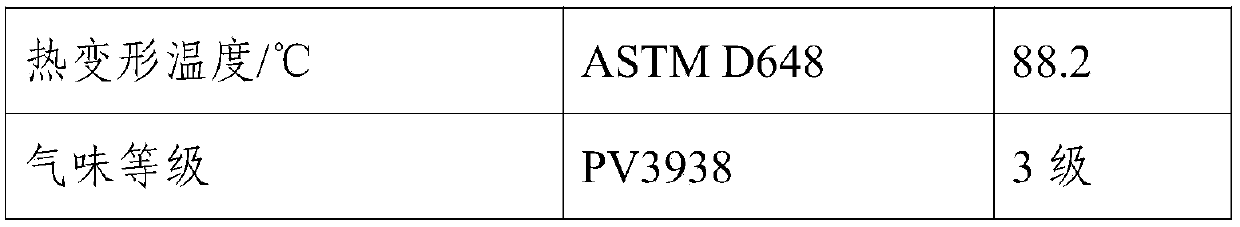

Embodiment 1

[0025] Weigh 90.46% of ABS resin, 10760.26% and 1680.78% of antioxidants, 0.5% of Ca-Zn heat stabilizer, and 3% of ABS-g-MAH compatibilizer, mix them uniformly in a high-speed premixer, and heat to 80°C Then keep warm for 30 minutes. Add the premixed material into the twin-screw extruder, and inject 2% of polyester plasticizer with a molecular weight of 2000 through a gear pump near the main feeding port. Add 3% organic chelating deodorant through the side feed port, and inject CO in the middle of the extruder 2 , the flow rate is 2.5m 3 / h, the vacuum pressure in the vacuum pumping section is -0.098MPa, and the ABS material is obtained by pelletizing, wherein the screw speed of the twin-screw extruder is 300rpm, and the barrel temperature is 190-260°C. The dried ABS granular material is introduced into a single-screw extruder, and after extrusion, it is pulled by a tractor to be processed into a 1.75±0.05mm wire that meets the requirements of a 3D printer. The screw speed o...

Embodiment 2

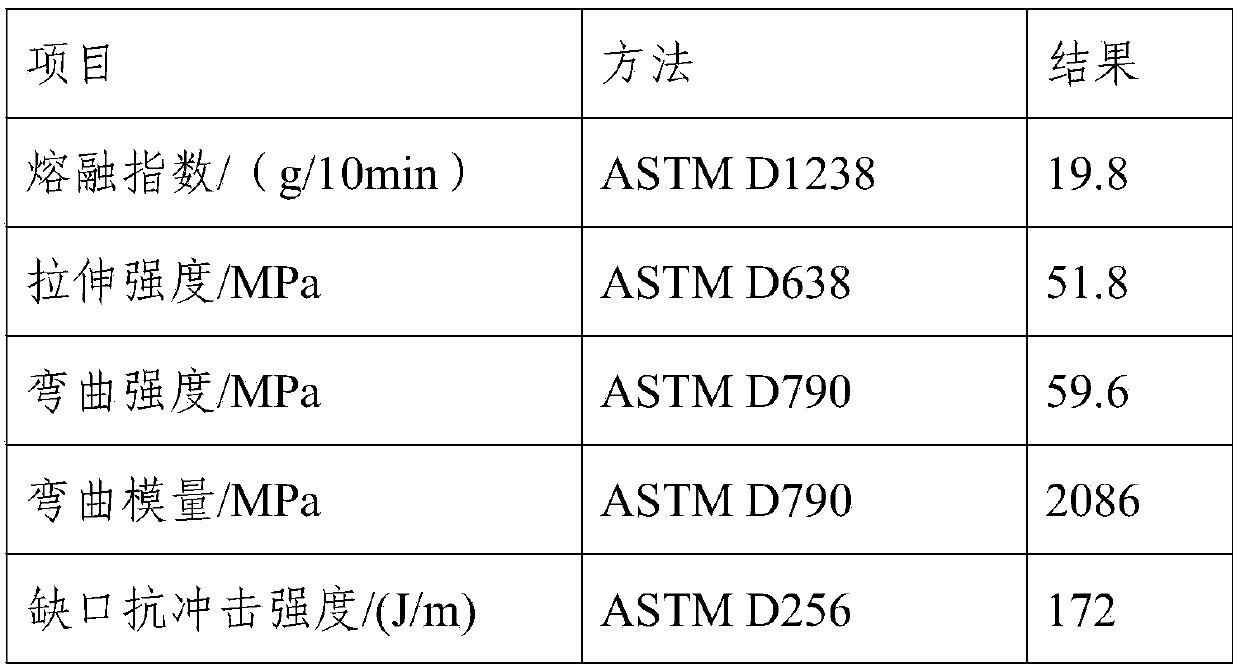

[0031] Weigh respectively 90.46% of ABS resin, 10760.26% and 1680.78% of antioxidant, 0.5% of Ca-Zn heat stabilizer, 3% of ABS-g-GMA compatibilizer, 2% of polyethylene wax with molecular weight of 2000 and premix at high speed Mix evenly in a container, heat to 80°C and keep warm for 30 minutes. Add the premix into the twin-screw extruder, add 3% deodorant organic chelating deodorant through the side feeding port, and inject CO into the middle of the extruder 2 , the flow rate is 2m 3 / h, the vacuum pressure in the vacuum pumping section is -0.098MPa, and the ABS material is obtained by pelletizing, wherein the screw speed of the twin-screw extruder is 300rpm, and the barrel temperature is 190-260°C. The dried ABS granular material is introduced into a single-screw extruder, and after extrusion, it is pulled by a tractor to be processed into a 1.75±0.05mm wire that meets the requirements of a 3D printer. The screw speed of the single-screw extruder is 50rpm, and the barrel te...

Embodiment 3

[0037] Weigh 88.46% of ABS resin, 10760.26% and 1680.78% of antioxidants, 0.5% of Ca-Zn heat stabilizer, and 3% of ABS-g-MAH compatibilizer, mix them uniformly in a high-speed premixer, and heat to 80°C Then keep warm for 30 minutes. The premix is added into the twin-screw extruder, and 4% of polyester plasticizer with a molecular weight of 2000 is injected through a gear pump near the main feeding port. Add deodorant porous aluminum silicon 3% through the side feed port, inject CO in the middle of the extruder 2 , the flow rate is 2.5m 3 / h, the vacuum pressure in the vacuum pumping section is -0.098MPa, and the PC / ABS alloy material is obtained by pelletizing, wherein the screw speed of the twin-screw extruder is 300rpm, and the barrel temperature is 190-260°C. The dried ABS granular material is introduced into a single-screw extruder, and after extrusion, it is pulled by a tractor to be processed into a 1.75±0.05mm wire that meets the requirements of a 3D printer. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com