Coal tar treatment method based on supercritical methanol

A technology of supercritical methanol and a treatment method, applied in the field of coal tar treatment based on supercritical methanol, can solve the problems of high cost, difficult operation, increased cost, etc., and achieve the effects of weakening association, strong dissolving ability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

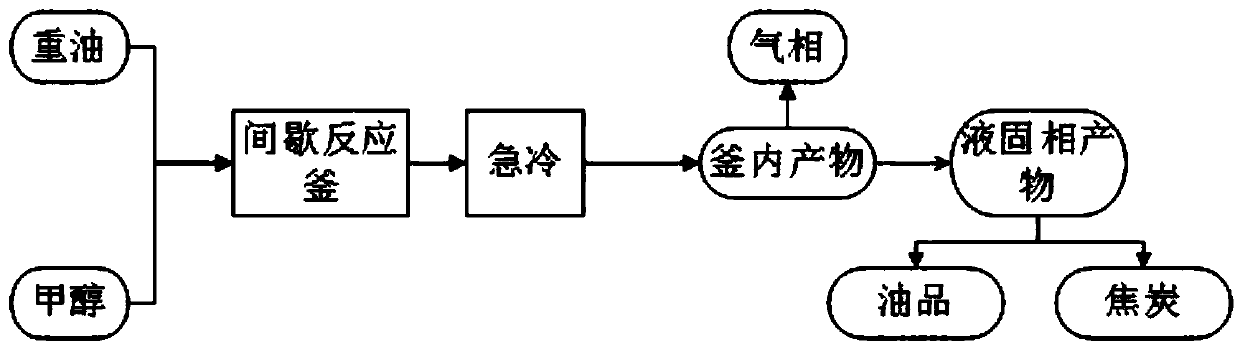

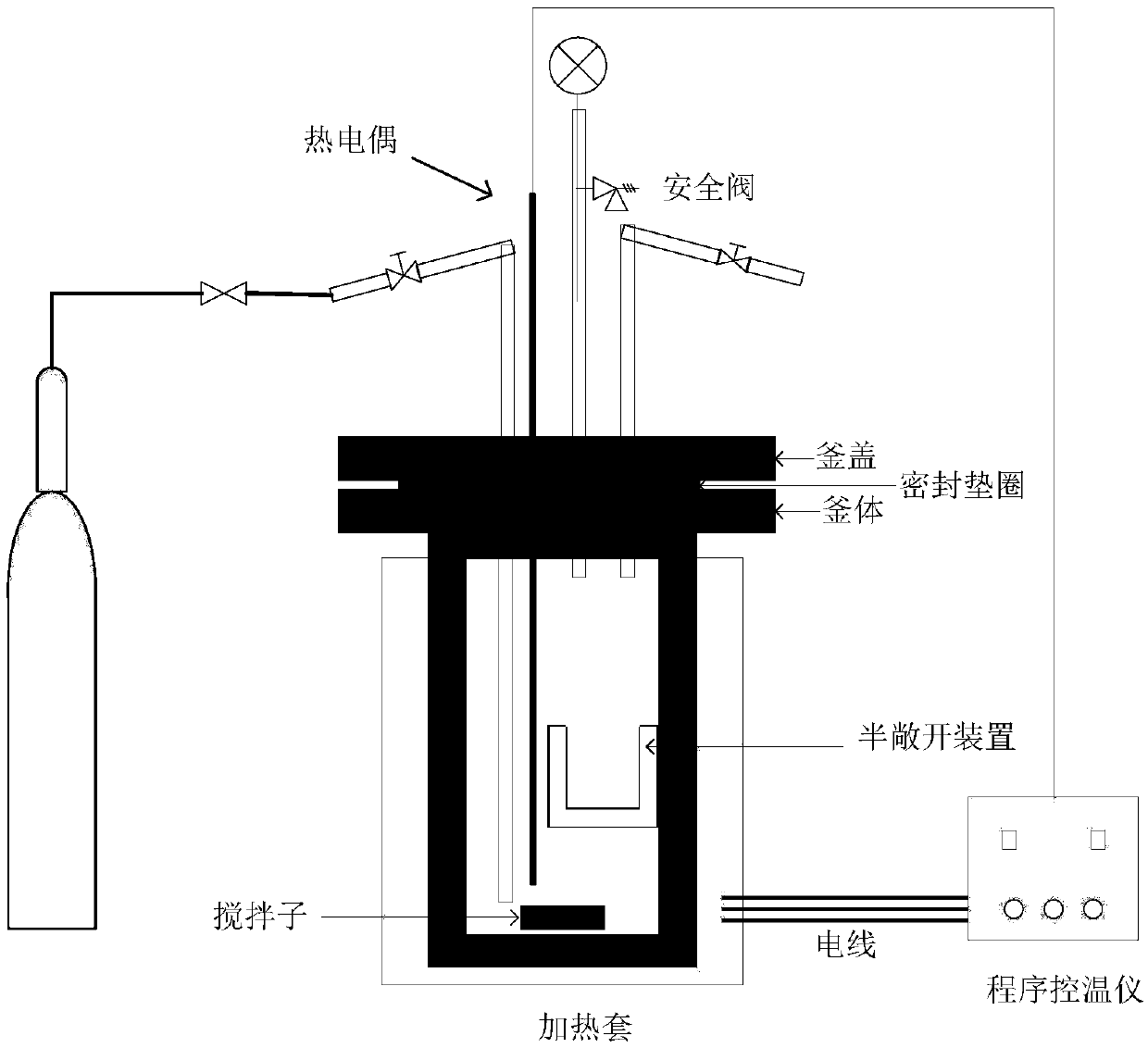

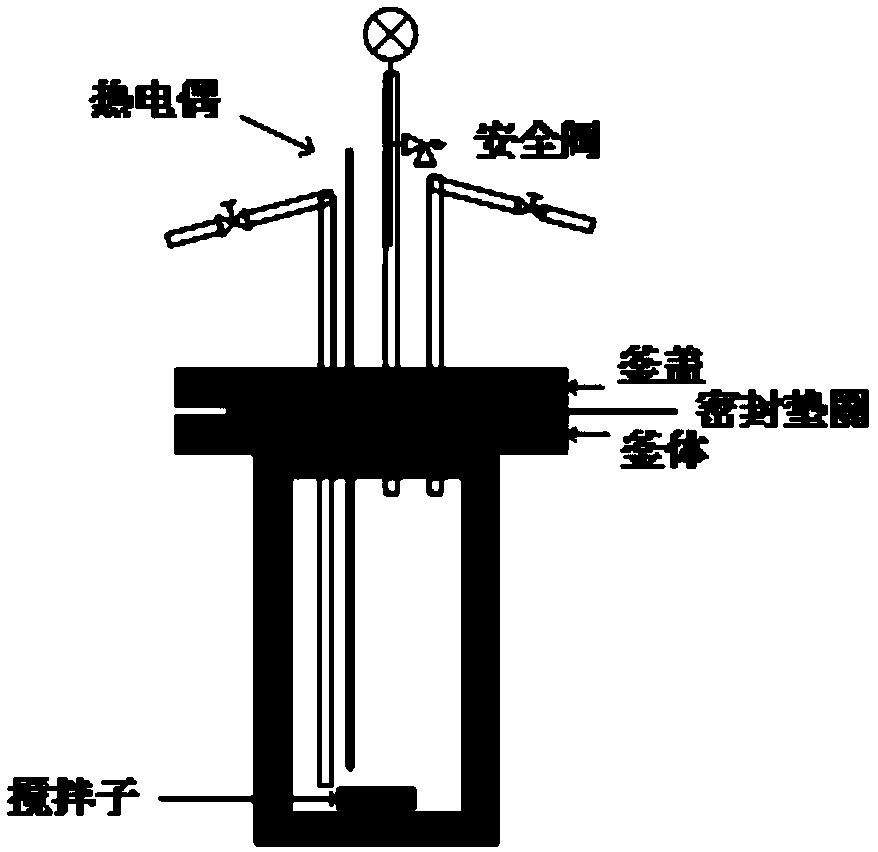

[0039] The raw material is selected from Shaanxi coal medium and low temperature coal tar, and the raw material properties are as follows in Table 1. This embodiment is carried out in a batch reactor without adding a semi-open device. The solvent of the batch reactor is 200ml, and the magnetic stirrer and The stirrer base is combined, and the batch reactor is shown in Figure 3 (a), and the volume of the batch reactor is 200ml. Process such as figure 1 As shown, 10g of coal tar and 20g of supercritical methanol are placed in a batch reactor (that is, the ratio of alcohol to oil is 2:1), and the bottom of the tank is fed, that is, no semi-open device is added. After sealing, purge with argon for 5 minutes to ensure that there is no air remaining in the kettle. Then set the parameters of the temperature controller, such as figure 2As shown, the batch reaction kettle was placed in a heating mantle, and the temperature inside the kettle was heated from room temperature 20°C to 4...

Embodiment 2

[0048] The selection of embodiment 2 is Shaanxi coal medium and low temperature coal tar (same as embodiment 1), and the addition of coal tar quality, feeding method, reaction equipment and detection equipment is the same as example 1, and the heating time, reaction time, alcohol-oil ratio, distillation of product The range distribution and heteroelement content are shown in Table 1. From Example 1 and Example 2, the yield of light oil (IBP-350 ° C) is significantly improved relative to raw material coal tar, and the yield of distillation range 350-750 ° C (heavy components) is reduced to a certain extent, indicating that after super After critical methanol treatment, the coal tar is lightened. In addition, the content of N elements decreased, which also confirmed that coal tar has a certain denitrification effect.

[0049] Table 1 embodiment 1 and 2 reaction conditions and result comparison

[0050] project

Embodiment 3-6

[0052] The selection of embodiment 3-6 is Shaanxi coal medium and low temperature coal tar (same as embodiment 1), adding coal tar quality, feeding method, reaction equipment, detection equipment are the same as example 1, heating time, reaction time, alcohol-oil ratio, product The yield of each distillation range is as table 2. Compared with the raw material coal tar, the yield of light oil in the product has been significantly increased, and the yield of the distillation range 350-750 ° C (heavy components) has decreased to a certain extent, indicating that after supercritical methanol treatment, coal tar has achieved light weight .

[0053] Table 2 Example 3-6 reaction conditions and product comparison

[0054] project

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com