A kind of multifunctional superamphiphobic fabric and its preparation method and application

A super-amphiphobic and multi-functional technology, applied in the field of super-amphiphobic, can solve the problems of reduced separation efficiency and impact on application, and achieve the effects of short reaction time, easy operation and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

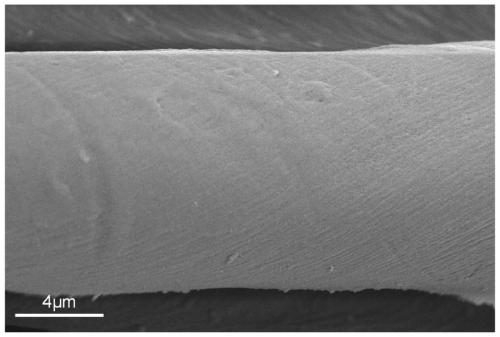

[0052] 1) Ultrasonic cleaning of cotton fabrics (size 3cm×3cm) with deionized water and ethanol for 15 minutes respectively, and drying at 50°C;

[0053] 2) preparing a mass fraction of 10wt% gamma-mercaptopropyltriethoxysilane and 30wt% ethanol mixed solution of ethyl orthosilicate;

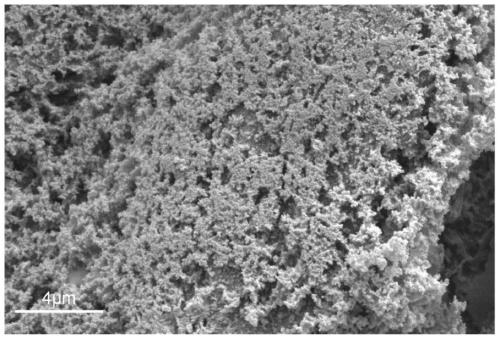

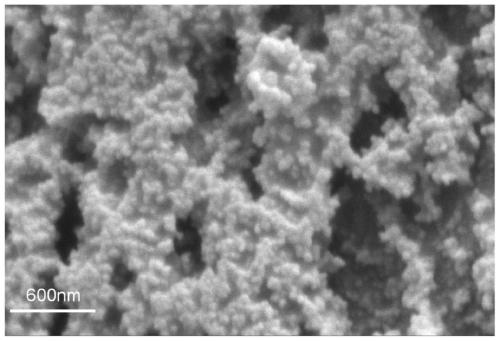

[0054] 3 Soak the fabric treated in step 1) into the solution obtained in step 2) for 5 minutes, then put it into a reaction vessel containing ammonia gas and react at 45°C for 20 minutes. The ammonia gas in the reaction vessel is changed from 25 to 28% concentrated Ammonia water is produced, and the volume fraction of ammonia water is 1.5-10vt% (relative to the container body), and finally the fabric is put into drying at 80°C for 1 hour to obtain a fabric modified with mercapto-silica;

[0055] 4) Then prepare a tetrahydrofuran mixed solution containing 5 wt % 2-(perfluorooctyl) ethyl methacrylate and 0.05 wt % 2-hydroxy-2-methyl-1-phenyl-1-propanone;

[0056] 5) Put the mercaptosilica-modifi...

Embodiment 2

[0063] The polyester fabric (size 3cm×3cm) was ultrasonically cleaned with deionized water and ethanol for 15 minutes, and dried at 50°C; A mixed solution of ethyl acetate in ethanol; soak the fabric in the above solution for 5 minutes, then put it into a reaction vessel containing ammonia gas and react at 80°C for 120 minutes. The ammonia gas in the reaction vessel is produced by 25-28% concentrated ammonia water. The volume fraction is 1.5-10vt% (relative to the container body), and finally put the fabric into the oven at 80°C for 1 hour to obtain a fabric modified with mercapto-silica; then prepare 2-(perfluorooctyl) containing 5wt% Ethyl methacrylate and 0.05wt% tetrahydrofuran mixed solution of 2-hydroxy-2-methyl-1-phenyl-1-propanone; put the mercapto-silica-modified fabric into the light reaction solution at wavelength Irradiated under 360nm ultraviolet light for 1 h, washed with tetrahydrofuran to obtain a superamphiphobic fabric.

Embodiment 3

[0065] Cotton fabrics (size 3cm×3cm) were ultrasonically cleaned with deionized water and ethanol for 15 minutes, and dried at 50°C; Ethanol mixed solution of ester; soak the fabric in the above solution for 5 minutes, then put it into a reaction vessel containing ammonia gas and react at 45°C for 30 minutes. The ammonia gas in the reaction vessel is produced by 25-28% concentrated ammonia water, the volume fraction of ammonia water It is 1.5-10vt% (relative to the container body), and finally the fabric is put into 80°C and dried for 1 hour to obtain a fabric modified with mercapto-silica; methacrylic acid ester and 0.05wt% 2-hydroxyl-2-methyl-1-phenyl-1-propanone mixed solution in tetrahydrofuran; the fabric modified by mercapto-silica is put into the light reaction solution under the wavelength 360nm ultraviolet lamp After irradiating for 1 h, it was washed with tetrahydrofuran to obtain a superamphiphobic fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com