Novel method for preparing artificial stress corrosion crack by utilizing photoetching and powder metallurgy technology

A stress corrosion cracking and powder metallurgy technology is applied in the field of preparation of stress corrosion cracking simulation specimens, which can solve the problems of difficult preparation of artificial stress corrosion cracking specimens, unknown electrical conductivity in cracked crack areas, etc., and achieves easy realization and low processing cost. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

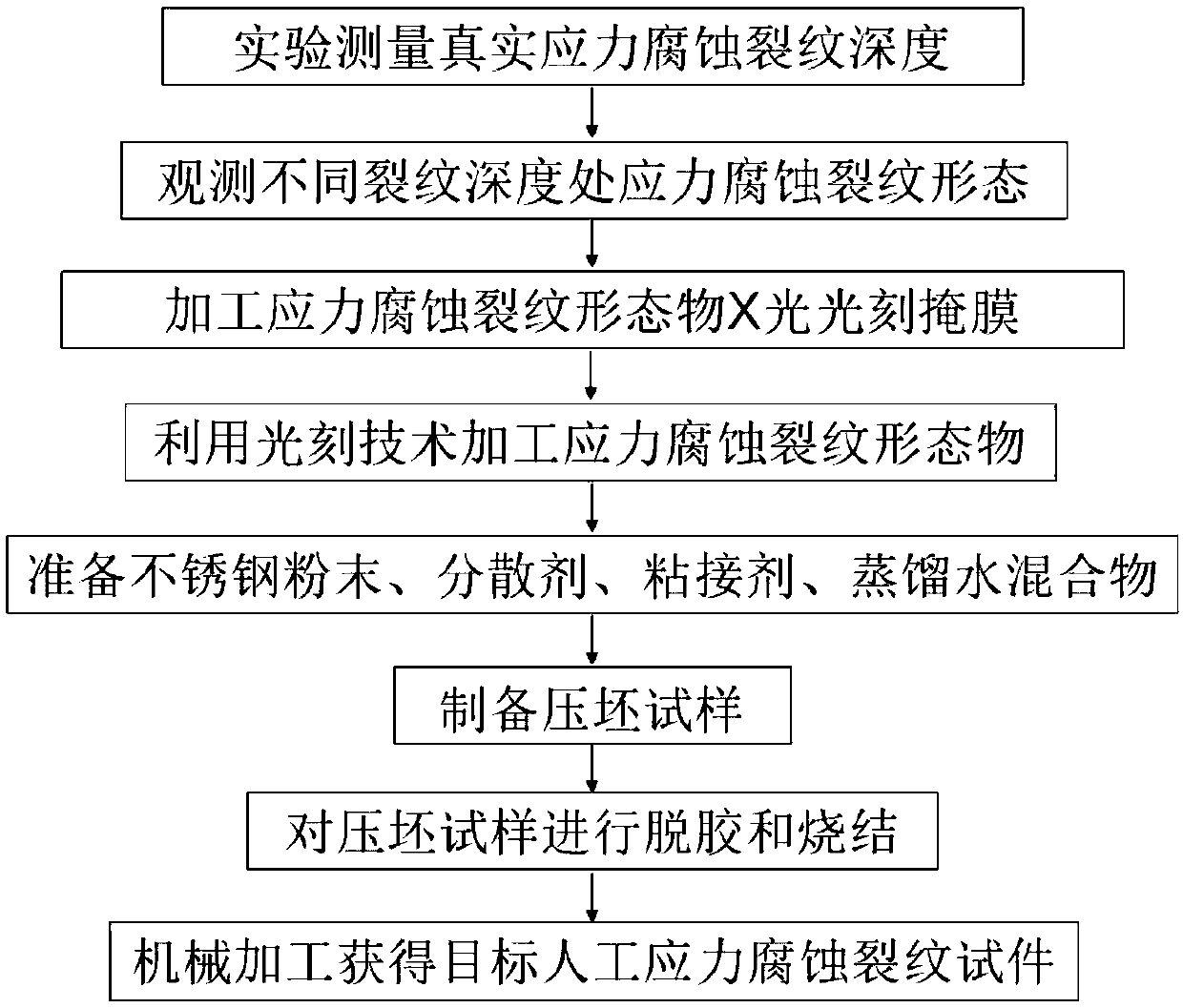

[0033] In this embodiment, a new method for preparing artificial stress corrosion cracks using photolithography and powder metallurgy technology includes the following steps:

[0034] Step 1: Processing of stress corrosion crack morphology based on photolithography and electroplating technology, the specific steps are as follows:

[0035] 1) For example figure 2 For the real stress corrosion crack test piece shown, the depth of the real stress corrosion crack is measured by TOFD ultrasonic testing equipment;

[0036] 2) Observe the morphology of surface stress corrosion cracks through a microscope to obtain the surface crack morphology diagram of the real stress corrosion cracked specimen;

[0037] 3) On the transparent film, print the surface crack morphology diagram of the real stress corrosion cracked specimen obtained in step 2), such as image 3 As shown, a carbon plate is selected as the substrate, a thin layer of photoresist is laid on the carbon plate substrate, and...

Embodiment 2

[0047] In this embodiment, a new method for preparing artificial stress corrosion cracks using photolithography and powder metallurgy technology includes the following steps:

[0048] Step 1: a new method for preparing artificial stress corrosion cracks by photolithography and powder metallurgy technology, characterized in that: comprising the following steps:

[0049] Step 1: Processing of stress corrosion crack morphology based on photolithography and electroplating technology, the specific steps are as follows:

[0050] 1) For example figure 2 For the real stress corrosion crack test piece shown, the depth of the real stress corrosion crack is measured by TOFD ultrasonic testing equipment;

[0051] 2) Observe the morphology of surface stress corrosion cracks through a microscope to obtain the surface crack morphology diagram of the real stress corrosion cracked specimen;

[0052] 3) On the transparent film, print the surface crack morphology diagram of the real stress co...

Embodiment 3

[0062] In this embodiment, a new method for preparing artificial stress corrosion cracks using photolithography and powder metallurgy technology includes the following steps:

[0063] Step 1: Processing of stress corrosion crack morphology based on photolithography and electroplating technology, the specific steps are as follows:

[0064] 1) For example figure 2 For the real stress corrosion crack test piece shown, the depth of the real stress corrosion crack is measured by TOFD ultrasonic testing equipment;

[0065] 2) Observe the morphology of surface stress corrosion cracks through a microscope to obtain the surface crack morphology diagram of the real stress corrosion cracked specimen;

[0066] 3) On the transparent film, print the surface crack morphology diagram of the real stress corrosion cracked specimen obtained in step 2), such as image 3 As shown, a carbon plate is selected as the substrate, a thin layer of photoresist is laid on the carbon plate substrate, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com