Anode electrolyte, and trivalent iron ion/ bivalent iron ion redox couple-based biomass fuel cell

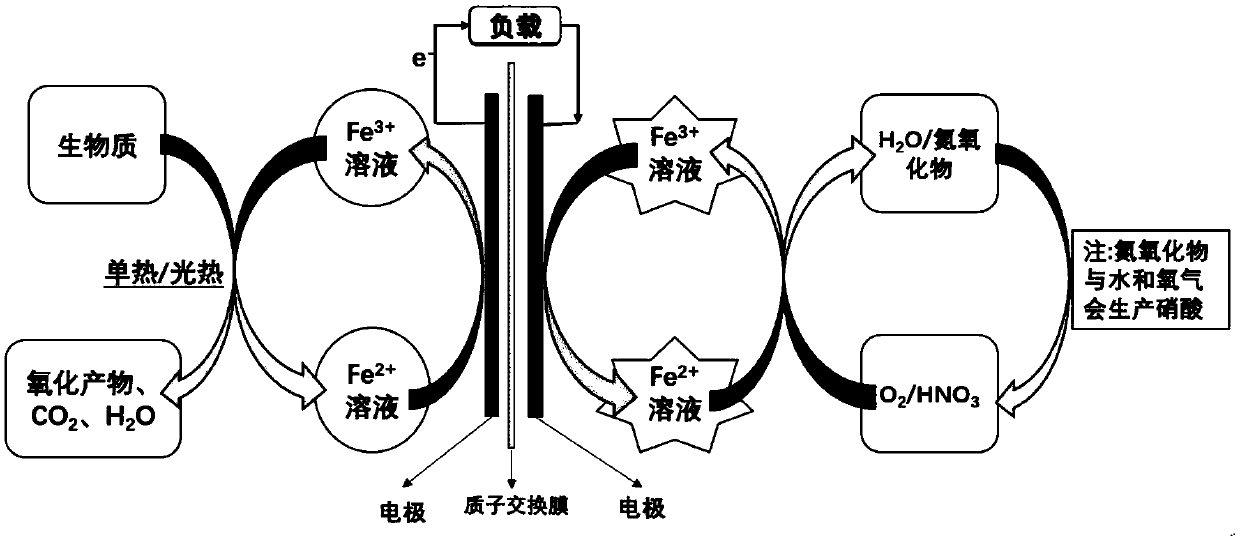

An anolyte and catholyte technology, used in biochemical fuel cells, regenerative fuel cells, fuel cells, etc., can solve the problems of limited metabolic capacity and lifespan of electricity-producing bacteria, high biomass storage and transportation costs, and harsh reaction conditions. , to achieve rich reserves, solve air pollution problems, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The embodiment of the present invention provides the first anolyte, and the specific steps are as follows:

[0056] 1. Dissolve 120g of ferric chloride hexahydrate and 45mL of concentrated hydrochloric acid in deionized water to prepare 300mL of ferric acid solution, then add 10g of bagasse, stir evenly, heat to 115°C for 5 hours, and filter the reaction solution to obtain A solid product is dried at a low temperature to obtain a solid product of bagasse oxidative degradation.

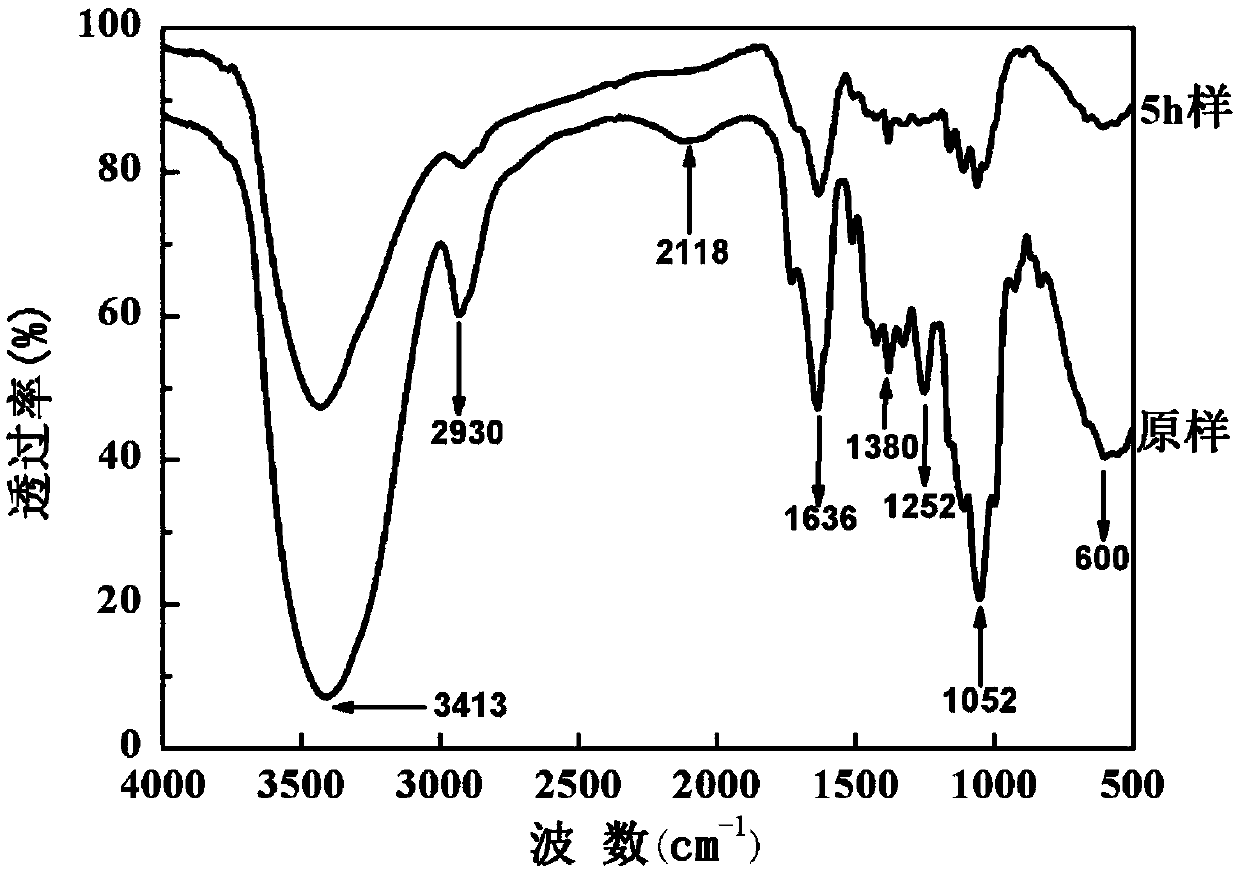

[0057] 2. Infrared test analysis: the bagasse before step 1 and the oxidative degradation product of bagasse obtained through oxidative degradation for 5 hours in step 1 were subjected to infrared test, and the results are shown in the attached figure 2 shown. Depend on figure 2 It can be seen that the infrared spectrum of the obtained bagasse oxidatively degraded solid product during the reaction for 5 hours is very different from the infrared spectrum of the non-oxidatively degraded bagass...

Embodiment 2

[0059] The embodiment of the present invention provides the first biomass fuel cell, and the specific steps are as follows:

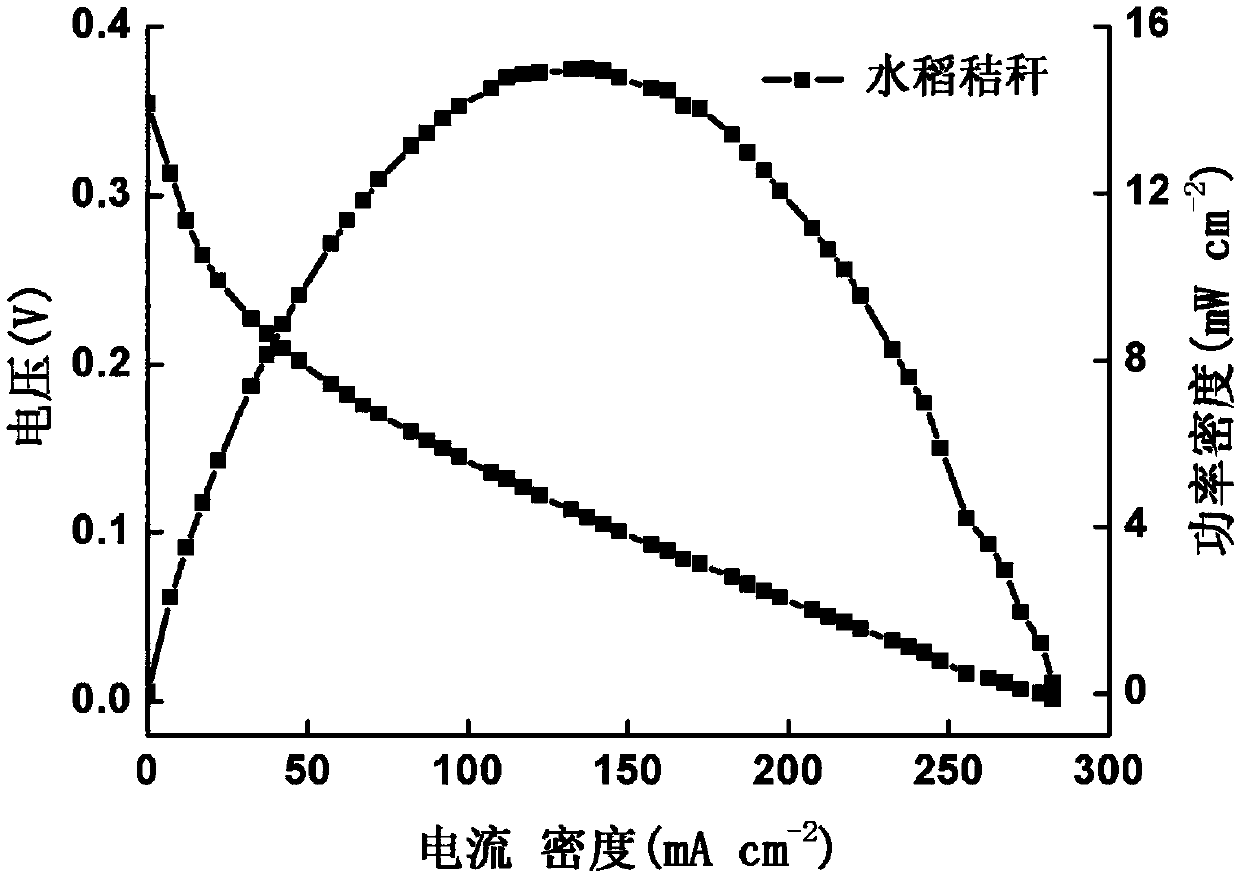

[0060] 1. Preparation of anolyte: Dissolve 120g of ferric chloride hexahydrate and 45mL of concentrated hydrochloric acid in deionized water to prepare 300mL of ferric acid solution, then add 5g of rice straw, stir well and heat to 100°C. And react at constant temperature for 5 hours to obtain the anolyte.

[0061] 2. Preparation of catholyte: 80 g of ferric chloride hexahydrate and 30 mL of concentrated hydrochloric acid were dissolved in deionized water to prepare 300 mL of ferric acid solution to obtain catholyte.

[0062] 3. Power generation performance test: put the anolyte in step 1 into the anolyte tank at 80°C, put the catholyte in step 2 into the catholyte tank at 80°C; The liquid is connected to the cathode pipe; the anode and the cathode are separated by the proton exchange membrane; the load is respectively connected to the anode and the ca...

Embodiment 3

[0064] The embodiment of the present invention provides the second biomass fuel cell, and the specific steps are as follows:

[0065] 1. Preparation of anolyte: Dissolve 120g of ferric chloride hexahydrate and 45mL of concentrated hydrochloric acid in deionized water to prepare 300mL of ferric acid solution, then add 5g of bagasse, stir well and heat to 100°C. And react at constant temperature for 5 hours to obtain the anolyte.

[0066] 2. Preparation of catholyte: 80 g of ferric chloride hexahydrate and 30 mL of concentrated hydrochloric acid were dissolved in deionized water to prepare 300 mL of ferric acid solution to obtain catholyte.

[0067] 3. Power generation performance test: put the anolyte in step 1 into the anolyte tank at 80°C, put the catholyte in step 2 into the catholyte tank at 80°C; The liquid is connected to the cathode pipe; the anode and the cathode are separated by the proton exchange membrane; the load is respectively connected to the anode and the cath...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Maximum current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com