Preparing method of injectable sodium hyaluronate gel containing microballoons

A technology of sodium hyaluronate and microspheres, which is applied in the fields of medicine and cosmetic filling materials, can solve the problems of polylactic acid microsphere deposition and other problems, and achieve the effect of simple method, feasible operation and no irritating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of an injectable gel containing polylactic acid microspheres, specifically comprising the following steps:

[0038] Step S1, dissolving 2 g of sodium hyaluronate with a molecular weight of 200,000 to 400,000 Daltons in 98 mL of pure water to obtain an aqueous solution A with a solution concentration of 2%;

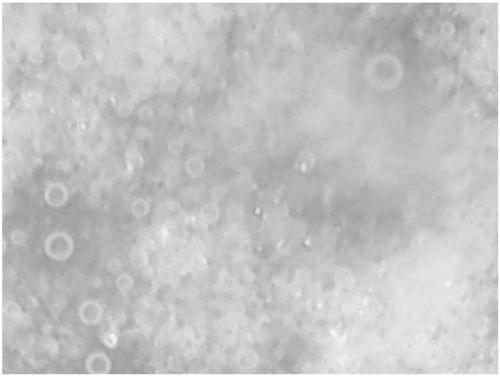

[0039] Step S2, adding 5 g of PLLA microspheres (L-polylactic acid microspheres, particle size of 20-40 nm, molecular weight of 100,000 Daltons) material to solution A, and uniformly dispersed suspension B was obtained after uniform stirring;

[0040] Step S3, adjusting the pH value of the suspension B to between 4.75-5.25 (1mol / L hydrochloric acid), to obtain the suspension C;

[0041] Step S4, add cross-linking agent and catalyst to the suspension C, the cross-linking agent is carbodiimide and adipic acid dihydrazide, and the catalyst is 1-hydroxybenzotriazole (sodium hyaluronate: dicarbide Imine: adipic acid dihydrazide: 1-hydroxybenzotriazole...

Embodiment 2

[0048] A preparation method of an injectable gel containing polycaprolactone microspheres, specifically comprising the following steps:

[0049] Step S1, dissolving 2 g of sodium hyaluronate with a molecular weight of 200,000 to 400,000 Daltons in 98 mL of pure water to obtain an aqueous solution A with a solution concentration of 2%;

[0050] Step S2, adding 5g of PCL microspheres (polycaprolactone, particle size 20-40nm, molecular weight at 50,000 Daltons) material to solution A, and evenly stirring to obtain a uniformly dispersed suspension B;

[0051] Step S3, adjusting the pH value of the suspension B to between 4.75-5.25 (1mol / L hydrochloric acid), to obtain the suspension C;

[0052] Step S4, add cross-linking agent and catalyst to the suspension C, the cross-linking agent is carbodiimide and adipic acid dihydrazide, and the catalyst is 1-hydroxybenzotriazole (sodium hyaluronate: dicarbide Imine: adipic acid dihydrazide: 1-hydroxybenzotriazole (1:3:1:3), and stirred un...

Embodiment 3

[0059] A preparation method for an injectable gel containing PLCL microspheres, specifically comprising the following steps:

[0060] Step S1, dissolving 2 g of sodium hyaluronate with a molecular weight of 1 million to 3 million Daltons in 48 mL of pure water to obtain an aqueous solution A with a solution concentration of 4%;

[0061] Step S2, add 2.5g PLCL microspheres (poly-L-lactic acid-polycaprolactone, particle size is 20-40nm, molecular weight is 30,000 Daltons) material to solution A, obtain uniformly dispersed suspension after uniform stirring Liquid B;

[0062] Step S3, adjusting the pH value of the suspension B to between 4.75-5.25 (1mol / L hydrochloric acid), to obtain the suspension C;

[0063] Step S4, add cross-linking agent and catalyst to the suspension C, the cross-linking agent is carbodiimide and adipic acid dihydrazide, and the catalyst is 1-hydroxybenzotriazole (sodium hyaluronate: dicarbide Imine: adipic acid dihydrazide: 1-hydroxybenzotriazole (1:3:1:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com