Special defoamer for alumina plant and preparation method thereof

A kind of technology of alumina plant and defoamer, which is applied in the direction of chemical instruments and methods, separation methods, foam dispersion/prevention, etc., can solve the problems of inability to achieve defoaming effect, high price, increase production cost, etc., and achieve defoaming performance The effects of stability, reduced dosing amount, and improved defoaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

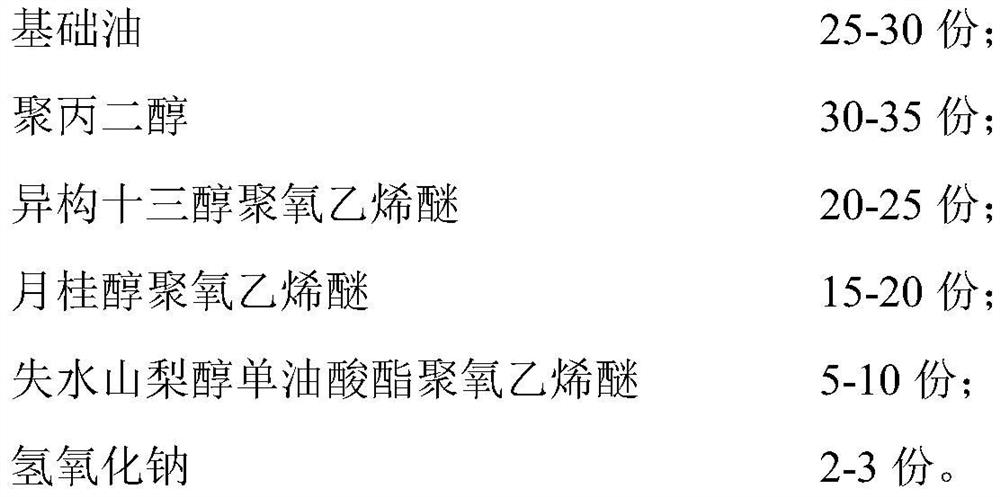

[0024] The raw materials and mass parts thereof of defoamer are as follows:

[0025]

[0026] First add isomeric tridecyl alcohol polyoxyethylene ether, lauryl alcohol polyoxyethylene ether, and polypropylene glycol into the reaction kettle in proportion, start stirring, raise the temperature to 45°C, and add sorbitan monooleate polyoxyethylene ether in proportion And paraffin-based neutral oil 150SN, stirring for 30min. Add 10wt% sodium hydroxide aqueous solution dropwise into the reaction kettle at a rate of 100L / h. After the dropwise addition, stir for another 30 minutes and cool down to room temperature to obtain the special defoamer for alumina plants.

Embodiment 2

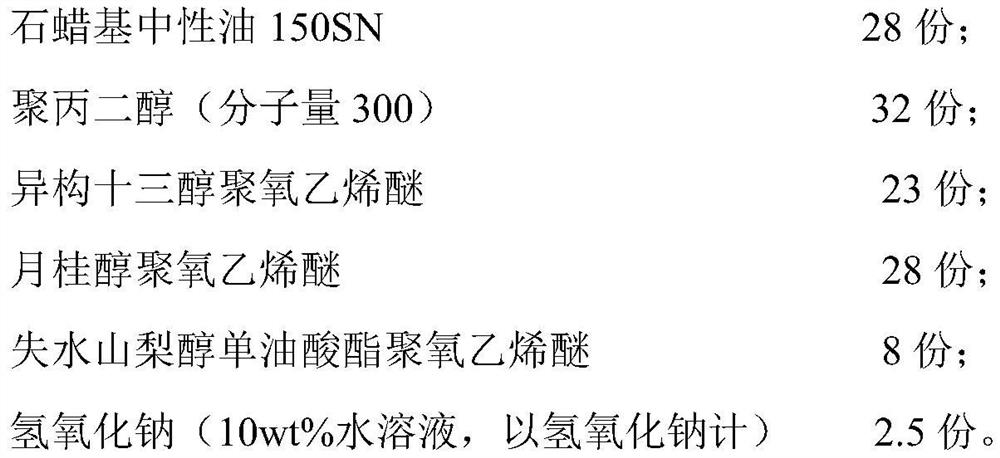

[0028] The raw materials and mass parts thereof of defoamer are as follows:

[0029]

[0030] First add isomeric tridecyl alcohol polyoxyethylene ether, lauryl alcohol polyoxyethylene ether, and polypropylene glycol into the reaction kettle in proportion, start stirring, raise the temperature to 50°C, and add sorbitan monooleate polyoxyethylene ether in proportion And paraffin-based neutral oil 60SN, stirring for 40min. Add 12wt% sodium hydroxide aqueous solution to the reactor dropwise at a rate of 80 L / h. After the dropwise addition, stir for another 20 minutes and cool down to room temperature to obtain the special defoamer for alumina plants.

Embodiment 3

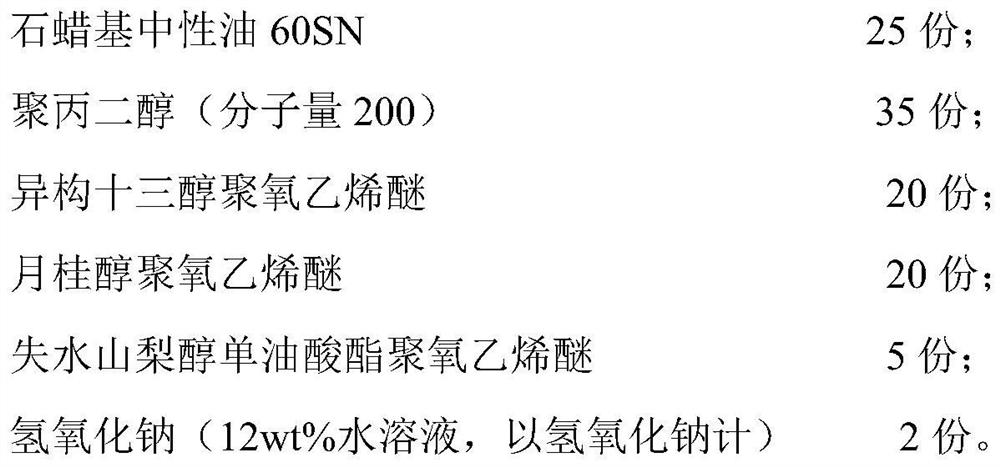

[0032] The raw materials and mass parts thereof of defoamer are as follows:

[0033]

[0034] First add isomeric tridecyl alcohol polyoxyethylene ether, lauryl alcohol polyoxyethylene ether, and polypropylene glycol into the reaction kettle in proportion, start stirring, raise the temperature to 50°C, and add sorbitan monooleate polyoxyethylene ether in proportion And paraffin-based neutral oil 60SN, paraffin-based neutral oil 150SN, stirred for 40min. Add 12wt% sodium hydroxide aqueous solution dropwise to the reactor at a rate of 90 L / h. After the dropwise addition, stir for another 30 minutes and cool down to room temperature to obtain the special defoamer for alumina plants.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com