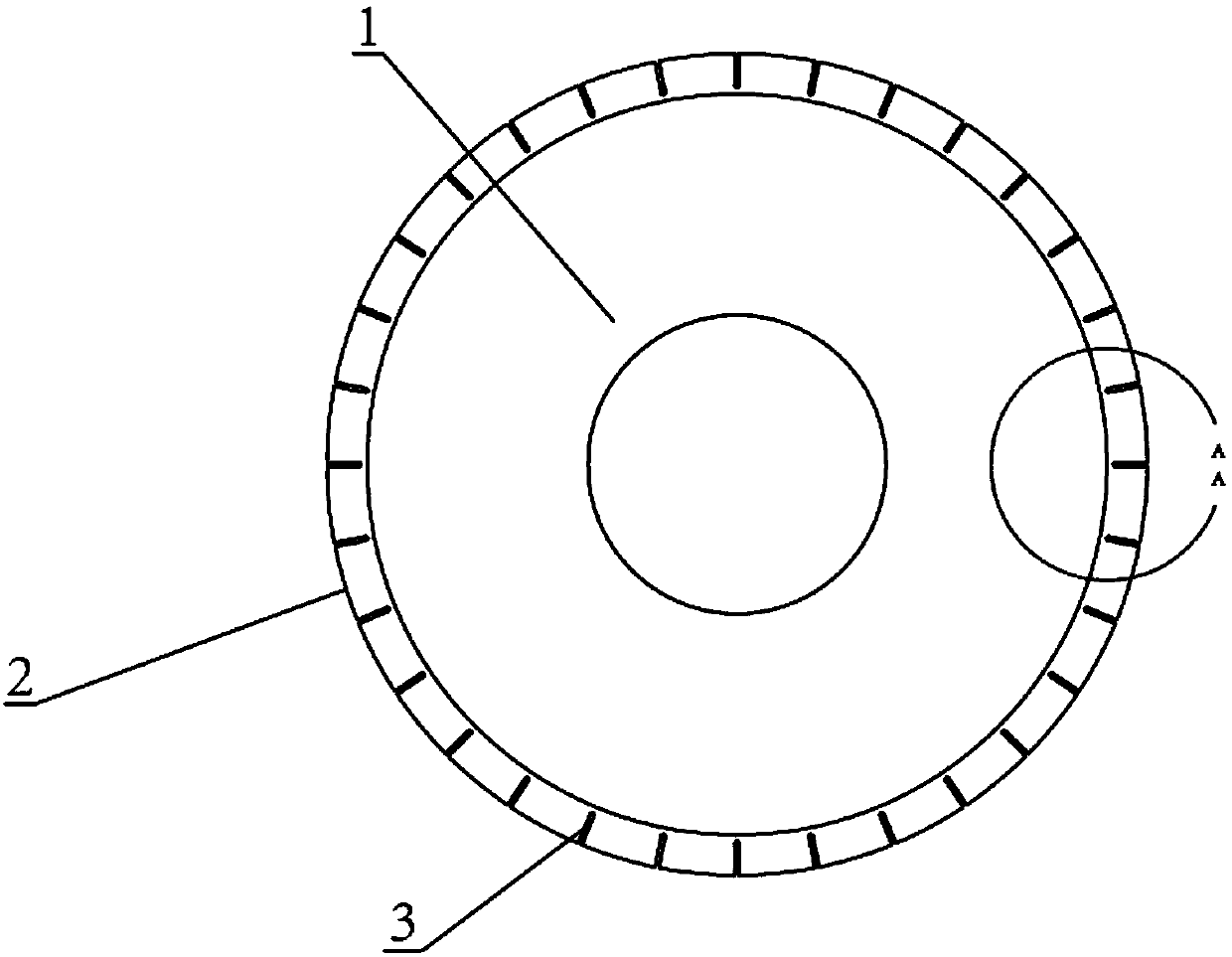

Hub type diamond ultra-thin cutting sheet for PCB and application thereof

A PCB board and diamond technology, applied in the field of grinding wheels, can solve the problems of diamond edge wear, cutting force reduction, product chipping, etc., and achieve the effect of improving flatness, reducing internal stress, and improving cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

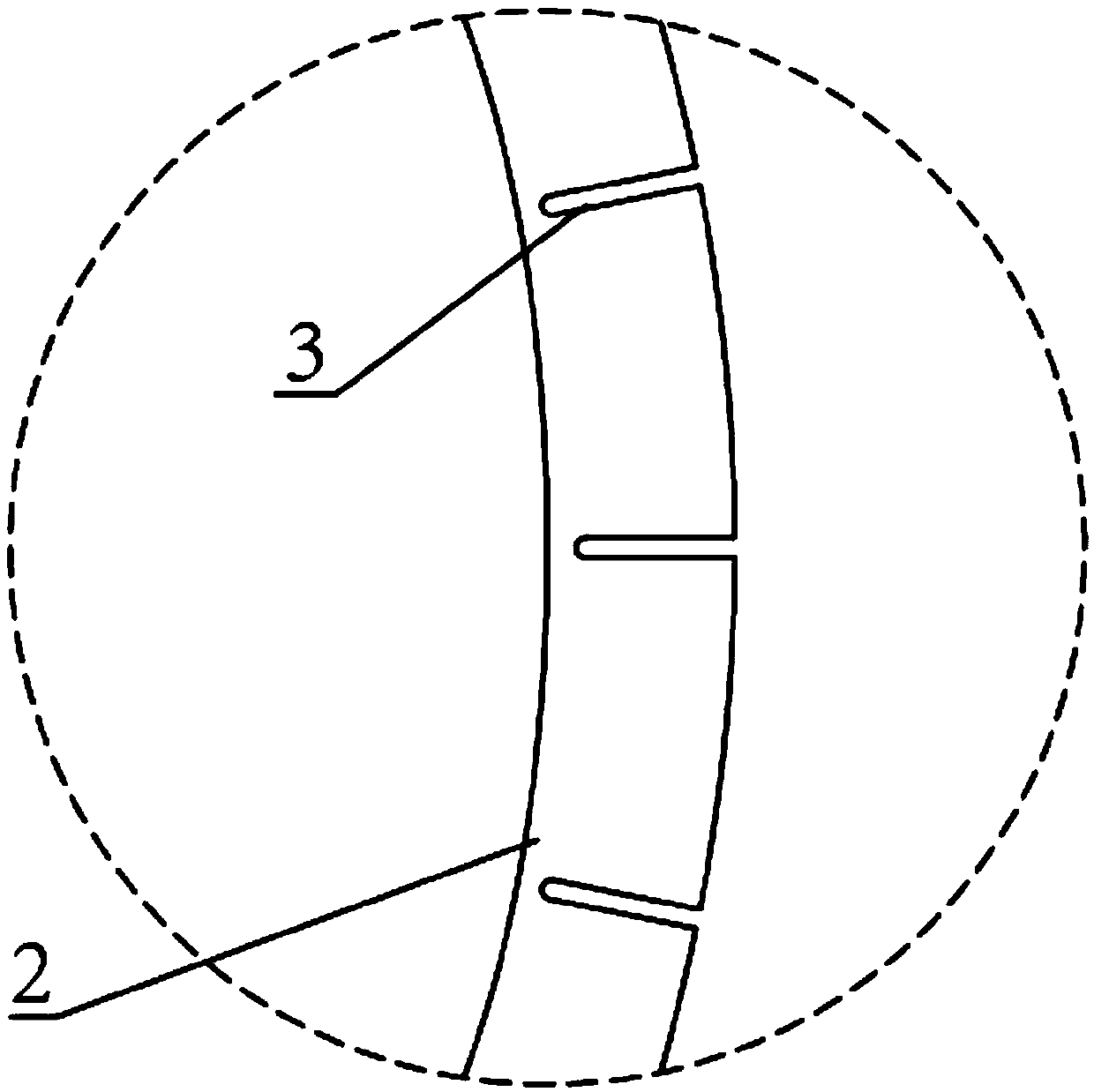

Method used

Image

Examples

Embodiment

[0044] 1. Equipped with electroplating solution, its formula is: nickel sulfate 400g / L, nickel chloride 40g / L, boric acid 35g / L, saccharin 0.5g / L, 1,4 butynediol 0.3g / L, and the rest is water.

[0045] 2. Select graphite powder with a particle size of 0.5-2 μm, put it in a beaker with diamond, add electroplating solution and disperse it with ultrasonic waves to obtain a mixed system, in which the concentration of graphite powder is 1g / L, and the concentration of diamond is 0.2g / L L; then add the aluminum substrate and electroplate at 40°C to obtain electroplated diamond ultra-thin cutting discs.

[0046] The method of stirring and sanding is adopted during electroplating, and the stirring is followed by high-speed stirring and low-speed stirring, so that the graphite powder and diamond are evenly distributed in the plating solution, and the pearl nickel coating with diamond is obtained, which is electroplated on the already prepared aluminum substrate; high-speed The rotation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com