Method for producing binary chloride-vinyl acetate resin by homogeneous solution polymerization method

A technology of binary chloroacetate resin and homogeneous solution, applied in the polymer field, can solve the problems of affecting polymer properties, difficult to discharge heat of polymerization, easy to explode and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

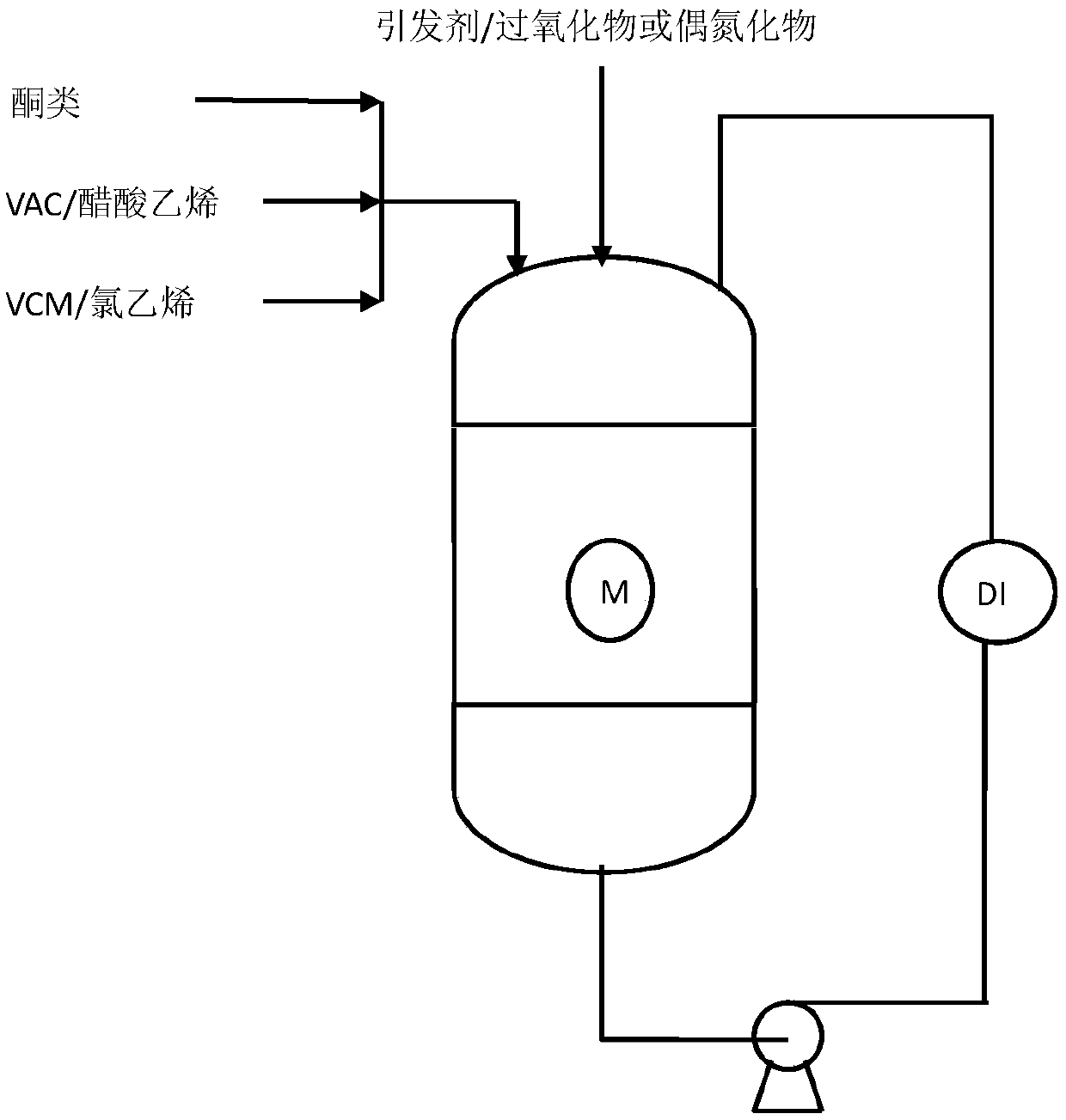

Method used

Image

Examples

Embodiment Construction

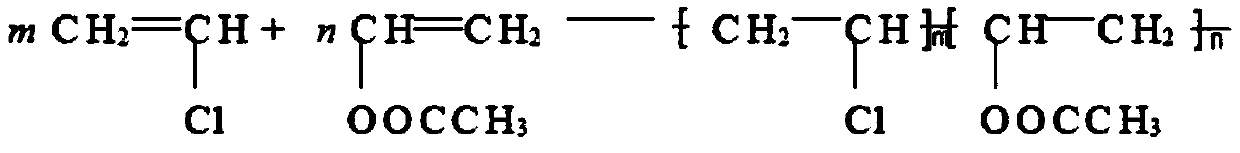

[0027] The reaction principle of the present invention is as follows:

[0028] Vinyl chloride resin solution polymerization uses IPP as the initiator, and dissolves in organic solvents together with vinyl chloride, vinyl acetate, etc., and is uniformly stirred by machinery, and then undergoes polymerization reaction.

[0029]

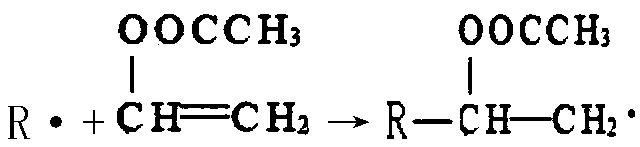

[0030] The reaction mechanism of the solution polymerization method is a chain reaction, and the reaction mechanism can be divided into four steps:

[0031] (1) chain initiation reaction

[0032] This stage is called the initiation stage. The initiator is affected by heat and decomposes to form a free radical R·, the reaction formula is: I→2R· (where I represents the initiator, R· represents the free radical). When the free radical R meets the monomer, it activates the monomer molecule and becomes an active monomer molecule.

[0033] R·+CH 2 =CHCL→R—CH 2 —CHCL·

[0034]

[0035] The process from the decomposition of the initiator to the acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com