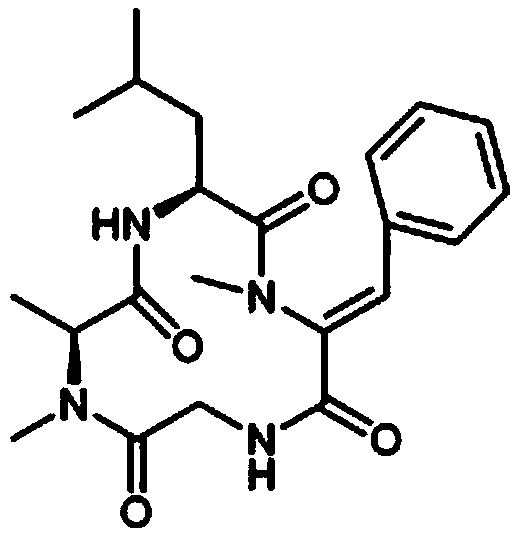

Application of virtual template in preparation of tentoxin molecularly imprinted polymer and preparation method of tentoxin molecularly imprinted polymer

A technology of molecular imprinting and virtual template, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as difficult separation of tentoxin, shorten the preparation cycle, improve detection efficiency and accuracy, and achieve the effect of high imprinting factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

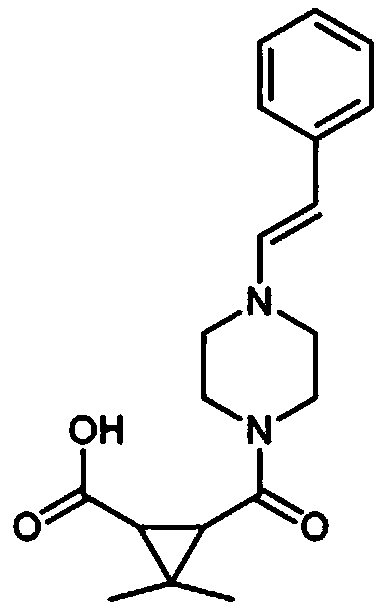

[0035] A preparation method of tenimotoxin molecularly imprinted polymer, comprising the following steps:

[0036] (1) Add 164mg of dummy template into a 150ml round-bottomed flask containing 50ml of acetonitrile and DMSO mixed solvent, wherein the volume ratio of acetonitrile and DMSO is 6:1, add 171mg of methacrylamide, stir at room temperature for 1h, add 1.98g Dimethacrylate oxalate, 72mg of azobisisobutyronitrile, then degassed by ultrasonic for 10min, placed on ice-water bath at 0-4℃ to deoxygenate by bubbling nitrogen for 10min, sealed and stirred for 24h, the reaction temperature was 60 ℃ to obtain molecularly imprinted polymers with virtual template molecules;

[0037] (2) Centrifuge the molecularly imprinted polymer with virtual template molecules obtained in step (1) at a speed of 10,000 rpm for 15 minutes to collect polymer particles;

[0038] (3) Add the polymer particles into a mixed solvent of methanol and acetic acid, the volume ratio of methanol and acetic ac...

Embodiment 2

[0040] A preparation method of tenimotoxin molecularly imprinted polymer, comprising the following steps:

[0041] (1) Add 202mg of dummy template into a 150ml round bottom flask containing 50ml of acetonitrile and DMSO mixed solvent, wherein the volume ratio of acetonitrile and DMSO is 6:1, add 606mg of methacrylamide, stir at room temperature for 1h, add 3.02g Dimethacrylate oxalate, 100mg azobisisobutyronitrile, then ultrasonically degassed for 10min, placed on an ice-water bath at 0-4°C for 10min with nitrogen bubbling to remove oxygen, sealed and stirred for 24h, the reaction temperature was 60 ℃ to obtain molecularly imprinted polymers with virtual template molecules;

[0042] (2) Centrifuge the molecularly imprinted polymer with virtual template molecules obtained in step (1) at a speed of 10,000 rpm for 15 minutes to collect polymer particles;

[0043](3) Add the polymer particles into a mixed solvent of methanol and acetic acid, the volume ratio of methanol and aceti...

Embodiment 3

[0045] A preparation method of tenimotoxin molecularly imprinted polymer, comprising the following steps:

[0046] (1) Add 250 mg of dummy template into a 150 ml round bottom flask containing 55 ml of acetonitrile and DMSO mixed solvent, where the volume ratio of acetonitrile and DMSO is 6:1, add 1.75 g of methacrylamide, stir at room temperature for 1 hour, add 4.45 g dimethacrylate oxalic acid ester, 80mg azobisisobutyronitrile, then degassed by ultrasonic for 10min, placed on an ice-water bath at 0-4°C for 10min by bubbling nitrogen to remove oxygen, sealed and stirred for 24h, the reaction temperature is At 60°C, molecularly imprinted polymers with virtual template molecules were obtained;

[0047] (2) Centrifuge the molecularly imprinted polymer with virtual template molecules obtained in step (1) at a speed of 10,000 rpm for 15 minutes to collect polymer particles;

[0048] (3) Add the polymer particles into a mixed solvent of methanol and acetic acid, the volume ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com