Transparent weather-proof halogen-free flame retardant PC/PETG alloy material

An alloy material and weather resistance technology, applied in the field of polymer composite materials, can solve the problems of poor solvent resistance, no material weather resistance, low temperature performance, stress cracking, etc. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

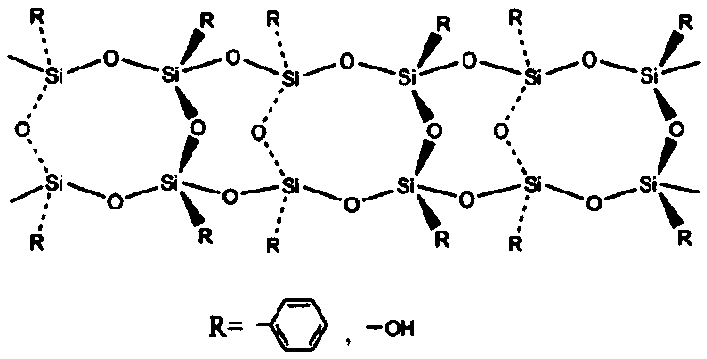

Image

Examples

Embodiment 1-6 and comparative example 1-5

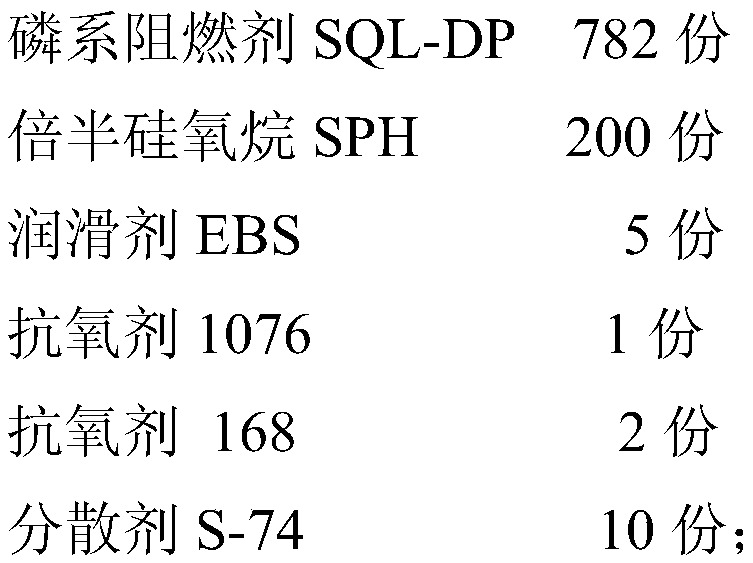

[0064] Components and proportioning of table 1 embodiment 1-6 and comparative example 1-5

[0065]

[0066]

[0067] Preparation:

[0068] Mix the above raw material components in a high-speed mixer for 6-8 minutes, then extrude, cool, and granulate through a twin-screw extruder. 260°C, 250°C, 250°C, 240°C, 240°C, 240°C, 240°C, 240°C, 240°C. The resulting pellets are dried at 100°C for 4 hours and then injection molded into standard strips at 240-260°C.

Embodiment 7

[0069] Embodiment 7: Evaluation of implementation effect

[0070] The samples obtained in the above-mentioned Examples 1-6 and Comparative Examples 1-5 were tested for mechanical properties according to the American Society for Testing and Materials (ASTM) standard, according to the light transmittance and haze of the ASTM D1003 standard test material, and according to the UL94 standard test material Flame retardancy, according to GB / T 2423-2013 program A method to test the weather resistance of the material (40 cycles), after weathering, evaluate the gray level of discoloration according to ISO105-A02, solvent resistance test method: the injected color Soak the board in ethyl acetate / glacial acetic acid (1:1) for 15 minutes, and evaluate whether there is any obvious change. The test results are shown in Table 2 below:

[0071] The test result of table 2 embodiment 1-6 and comparative example 1-5

[0072]

[0073] The performance test results in Table 2 show that:

[0074...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com