Saccharomyces cerevisiae gene engineering bacteria for knocking out FBP1 gene and construction method and application thereof

A technology of genetically engineered bacteria and Saccharomyces cerevisiae strains, applied in the field of genetic engineering, can solve problems such as affecting fermentation speed, hindering mass transfer, and not having obvious advantages in fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

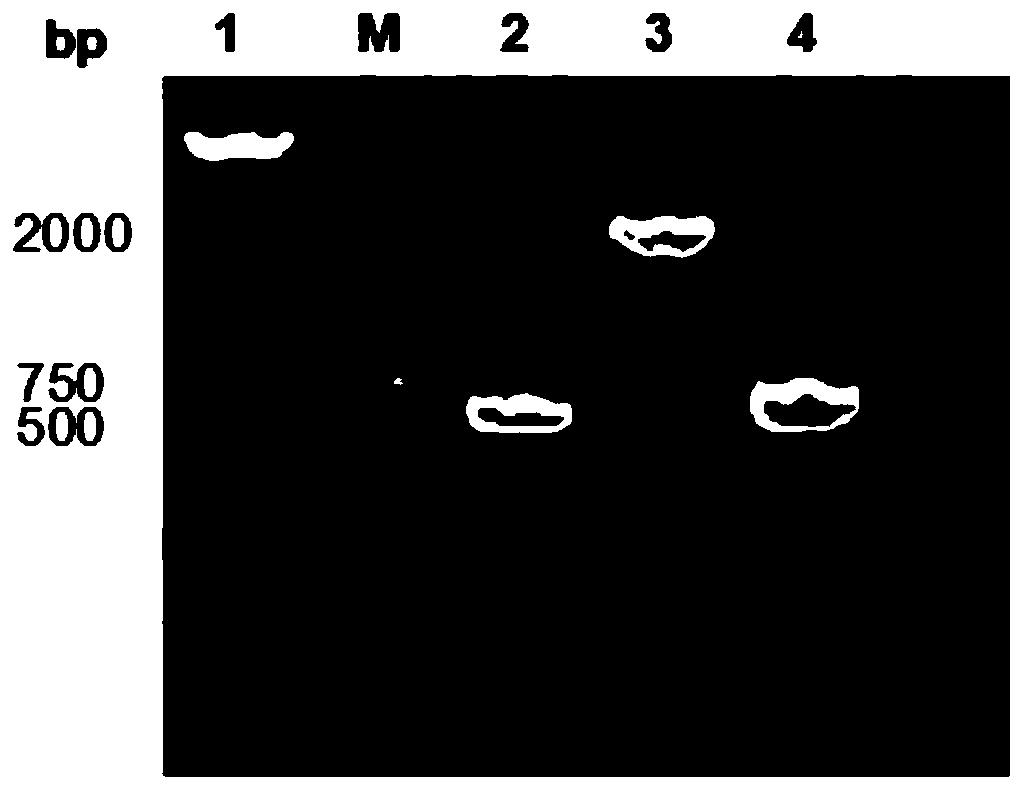

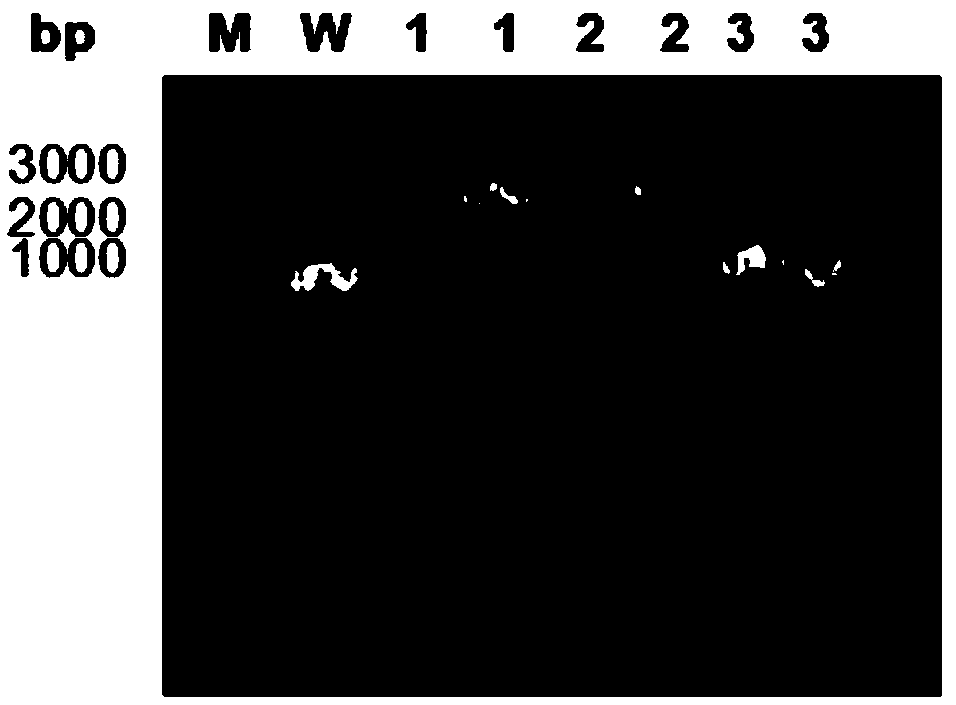

[0023] Example 1: Construction of FBP1 gene knockout Saccharomyces cerevisiae strain.

[0024] The primers used in the following examples are as follows:

[0025] AACGCTCTACCAACTGAGC (SEQ ID NO: 4, FBP1-up-F)

[0026] ATTCTGGGCCTCCATGTCCGTCTGTAATTGCACTACTTGT (SEQ ID NO:5, FBP1-up-R)

[0027] AAGTAGTGCAATTACAGACGGACATGGAGGCCCAGAATAC (SEQ ID NO: 6, AurR-F)

[0028] ACTGTGACTTGCCAATATGGCAGTATAGCGACCAGCATTC (SEQ ID NO:7, AurR-F)

[0029] ATGCTGGTCGCTATACTGCCATATTGGCAAGTCACAGTAG (SEQ ID NO: 8, FBP1-down-F)

[0030] GCGAATTCATGTAGATCGCG (SEQ ID NO:9, FBP1-down-F)

[0031] ATTCTTAGTAGTCGCGGTCG (SEQ ID NO: 10, YZ-F)

[0032] CAATGATGTGCAAGAACCCT (SEQ ID NO: 11, YZ-R)

[0033] 1. Construction of FBP1 knockout components.

[0034] (1) Utilize common PCR amplification to obtain the upper and lower homology arm amplification fragments of the yeast FBP1 gene (the upper homology arm amplification primer sequences FBP1-up-F, FBP1-up-R such as SEQ ID NO: 4 and SEQ ID NO: ID NO: shown ...

Embodiment 2

[0050] (1) Take 100 μL of glycerol bacteria S288c (starting bacteria) and S288c-FBP1 (knockout bacteria constructed in the present invention) and add them into sterilized 5mL YPD liquid medium for overnight culture and activation;

[0051] (2) According to the inoculation ratio of 10% by volume, transfer the bacterial solution in step (1) to 100 mL of YPD liquid medium, and continue to cultivate at 30° C. at 200 r / min until the OD600 of the bacterial solution is between 0.8 and 1.2;

[0052] (3) Take 2 mL of the bacterial solution to measure the absorbance value at OD600, and dilute the bacterial solution with sterilized YPD liquid medium so that the OD600 of the diluted bacterial solution is 0.01;

[0053] (4) Take 200 μL of bacterial solution and add it to a 96-well plate, and LB liquid medium as a control, and incubate at 37°C for 24 hours;

[0054] (5) Pour out the bacterial solution from the 96-well plate, buffer with pure water for 3 times, and pat dry;

[0055] (6) Add...

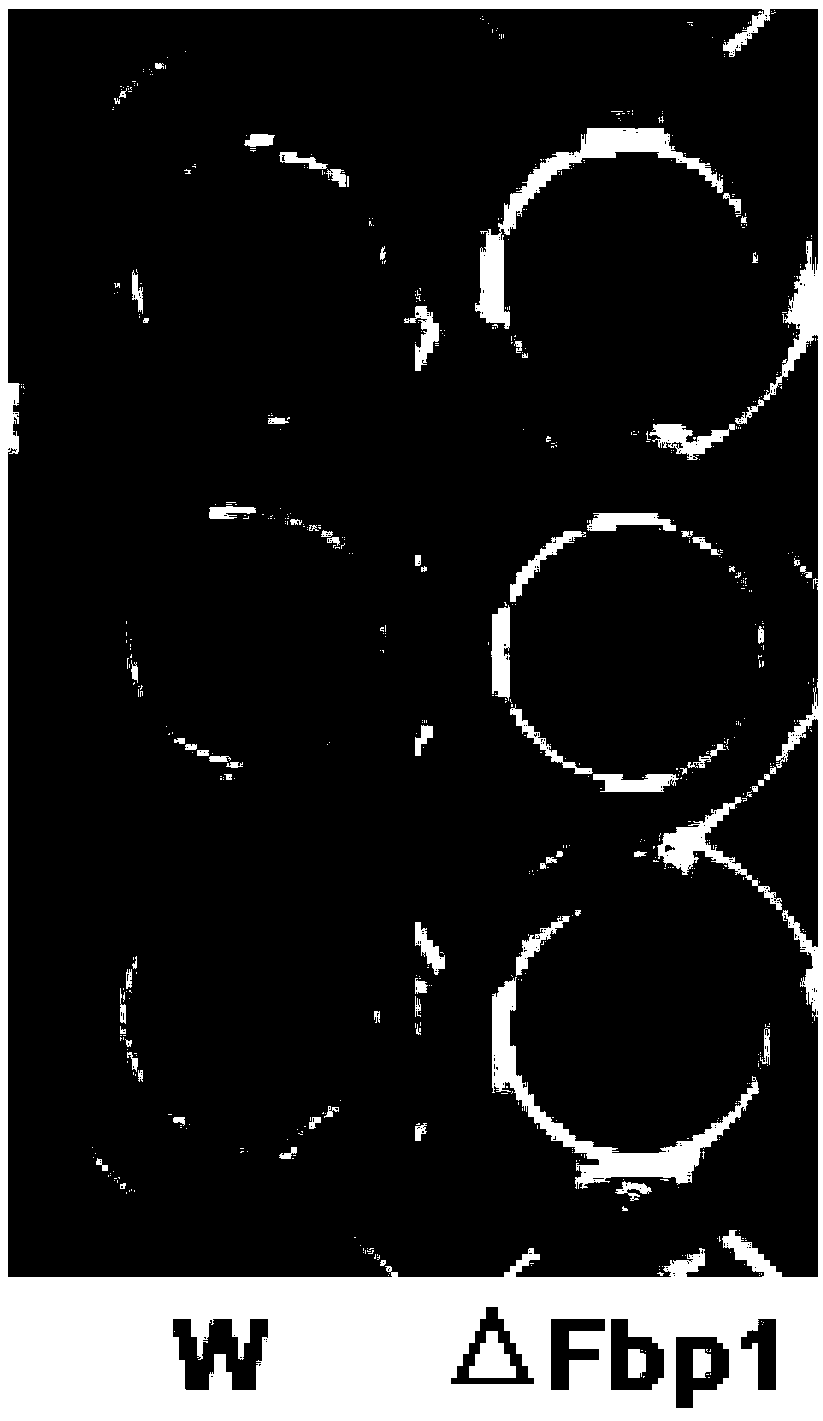

Embodiment 3

[0058] (1) Add 100 μL of glycerol bacteria S288c and S288c-FBP1 into sterilized 5 mL YPD liquid medium for overnight culture and activation;

[0059] (2) According to the inoculation ratio of 10% by volume, transfer the bacterial solution in step (1) to 100 mL of YPD liquid medium, and continue to cultivate at 30° C. at 200 r / min until the OD600 of the bacterial solution is between 0.8 and 1.2;

[0060] (3) Transfer the seed liquid of step (2) to 100mL fermentation medium, which is divided into two types: free fermentation and immobilized fermentation, and immobilized fermentation is added with cotton fiber material as immobilized material, at 35°C 200r / min Fermentation, the reaction ends after the glucose is exhausted, the residual sugar content of the fermentation broth is measured by a spectrophotometer, and the alcohol content in the fermentation broth is measured by a high-efficiency gas chromatograph;

[0061] Among them, the formula of the fermentation medium is as foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com