Electroluminescent devices based on nanocellulose-silver nanowires and their applications

An electroluminescent device and nanocellulose technology, applied in nonlinear optics, instruments, optics, etc., to solve oxidation problems, improve dispersion, and reduce roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

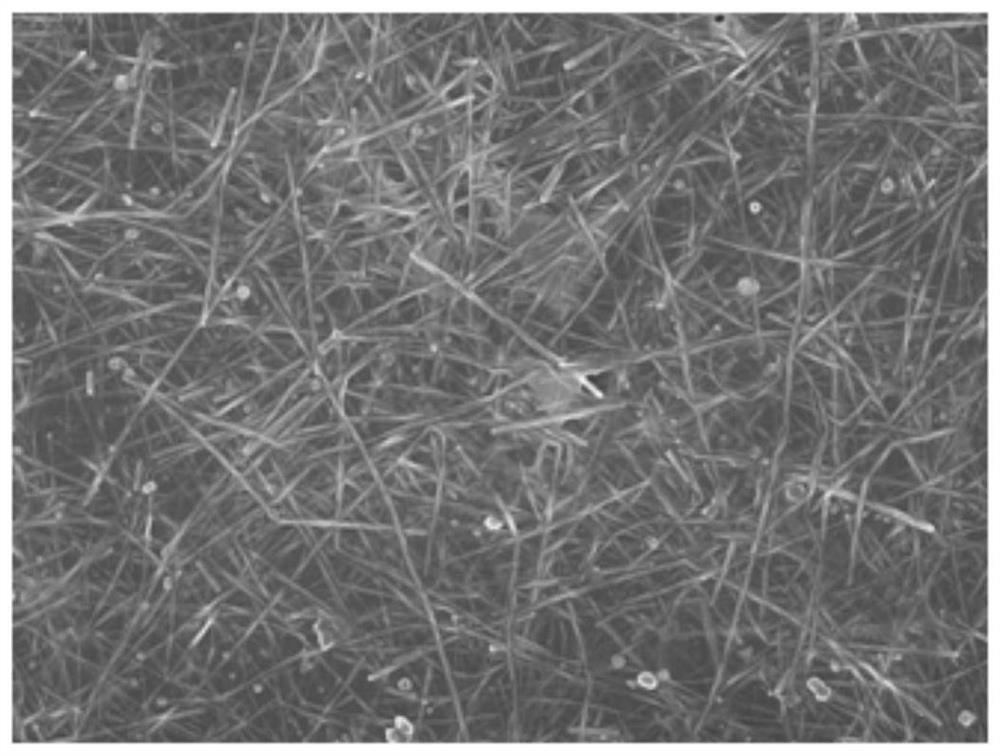

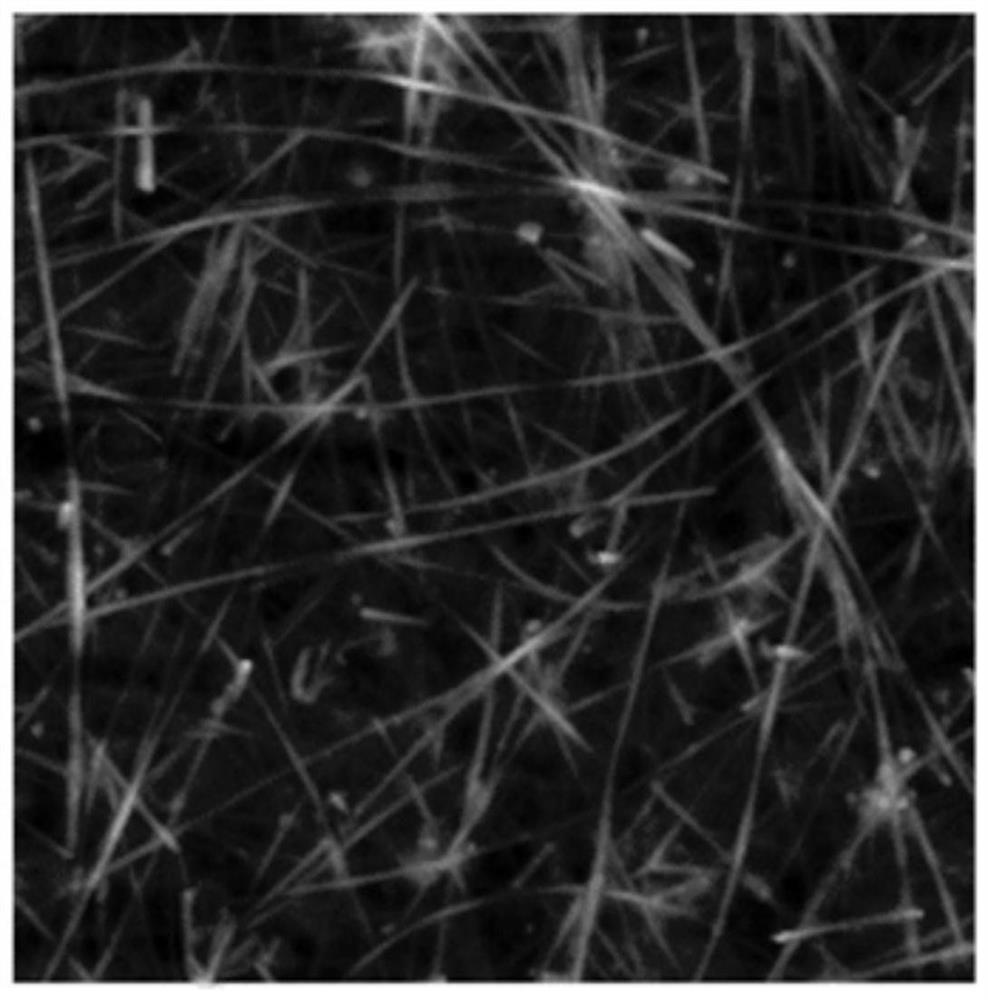

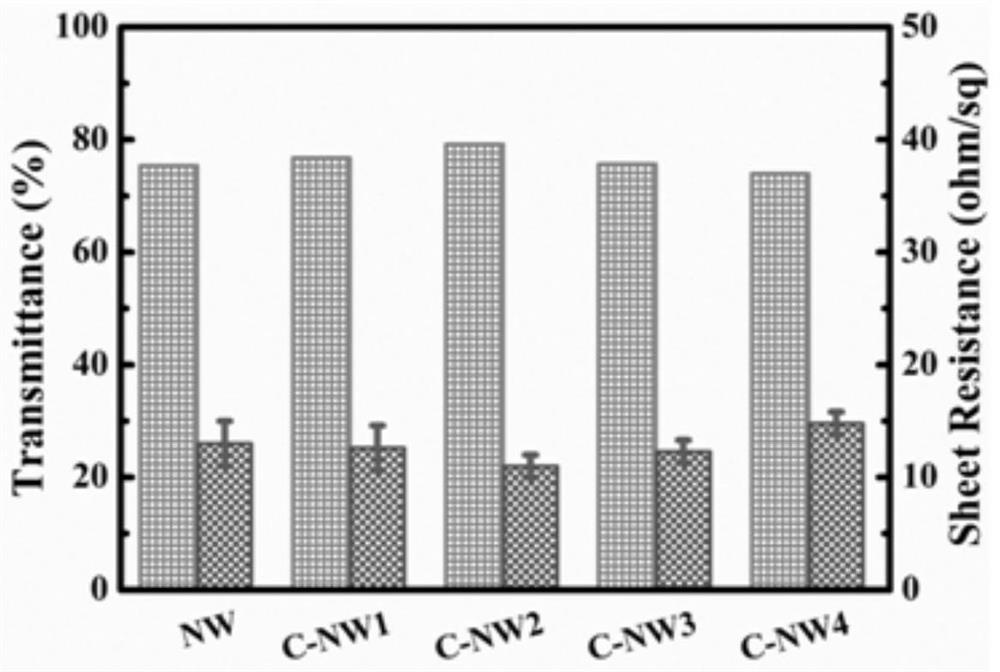

Image

Examples

Embodiment 1

[0054] Step 1, the preparation of polydimethylsiloxane film, its concrete method step comprises:

[0055] (1) Weigh 1 g of polydimethylsiloxane solution, add 0.1 g of curing agent, and fully stir the above mixture with a magnetic stirrer. Weigh 1.1 g of the mixed solution and spread it on a glass sheet, cure it in an oven at 80°C for 2 hours, and peel it off from the glass sheet; in the same way, prepare another polydimethylsiloxane film.

[0056] Step 2, the preparation of hydrophilic polydimethylsiloxane film, its concrete method step comprises:

[0057] (1) Place the polydimethylsiloxane film in H 2 O, HCl and H 2 o 2 The oxidizing solution prepared by mixing at a volume ratio of 2:1:1 was soaked for 5 minutes to react, oxidized the surface of the polydimethylsiloxane film, then rinsed with deionized water for 1 min, then rinsed with ethanol for 1 min, and dried with nitrogen; (2) Put the polydimethylsiloxane film into the 10:1 mixed solution of ethanol and water, add 2...

Embodiment 2

[0067] Step 1, the preparation of polydimethylsiloxane film, its concrete method step comprises:

[0068] (1) Weigh 2 g of polydimethylsiloxane solution, add 0.2 g of curing agent, and fully stir the above mixture with a magnetic stirrer. Weigh 1.1 g of the mixed solution and spread it on a glass sheet, cure it in an oven at 80°C for 2 hours, and peel it off from the glass sheet; in the same way, prepare another polydimethylsiloxane film.

[0069] Step 2, the preparation of hydrophilic polydimethylsiloxane film, its concrete method step comprises:

[0070] (1) Place the polydimethylsiloxane film in H 2 O, HCl and H 2 o 2 The oxidation solution prepared by mixing at a volume ratio of 5:1:1 was soaked for 5 minutes to react, and the surface of the polydimethylsiloxane film was oxidized, then rinsed with deionized water for 10 minutes, then rinsed with ethanol for 5 minutes, and dried with nitrogen; (2) Put the polydimethylsiloxane film into a 19:1 mixed solution of ethanol a...

Embodiment 3

[0080] Step 1, the preparation of polydimethylsiloxane film, its concrete method step comprises:

[0081] (1) Weigh 2 g of polydimethylsiloxane solution, add 0.2 g of curing agent, and fully stir the above mixture with a magnetic stirrer. Weigh 1.1 g of the mixed solution and spread it on a glass sheet, cure it in an oven at 80°C for 2 hours, and peel it off from the glass sheet; in the same way, prepare another polydimethylsiloxane film.

[0082] Step 2, the preparation of hydrophilic polydimethylsiloxane film, its concrete method step comprises:

[0083] (1) Place the polydimethylsiloxane film in H 2 O, HCl and H 2 o 2 The oxidation solution prepared by mixing at a volume ratio of 5:1:1 was soaked for 5 minutes to react, and the surface of the polydimethylsiloxane film was oxidized, then rinsed with deionized water for 10 minutes, then rinsed with ethanol for 5 minutes, and dried with nitrogen; (2) Put the polydimethylsiloxane film into a 19:1 mixed solution of ethanol a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com