Preparation method of mulberry fruit cake

A technology of mulberries and fruit cakes, applied in confectionary, confectionary industry, food science, etc., can solve the problems of insufficiently fine and smooth taste of mulberry seeds, high sugar content in products, loss of flavor substances, etc., and achieve flavor And the effect of improving the taste, rich flavor and high solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

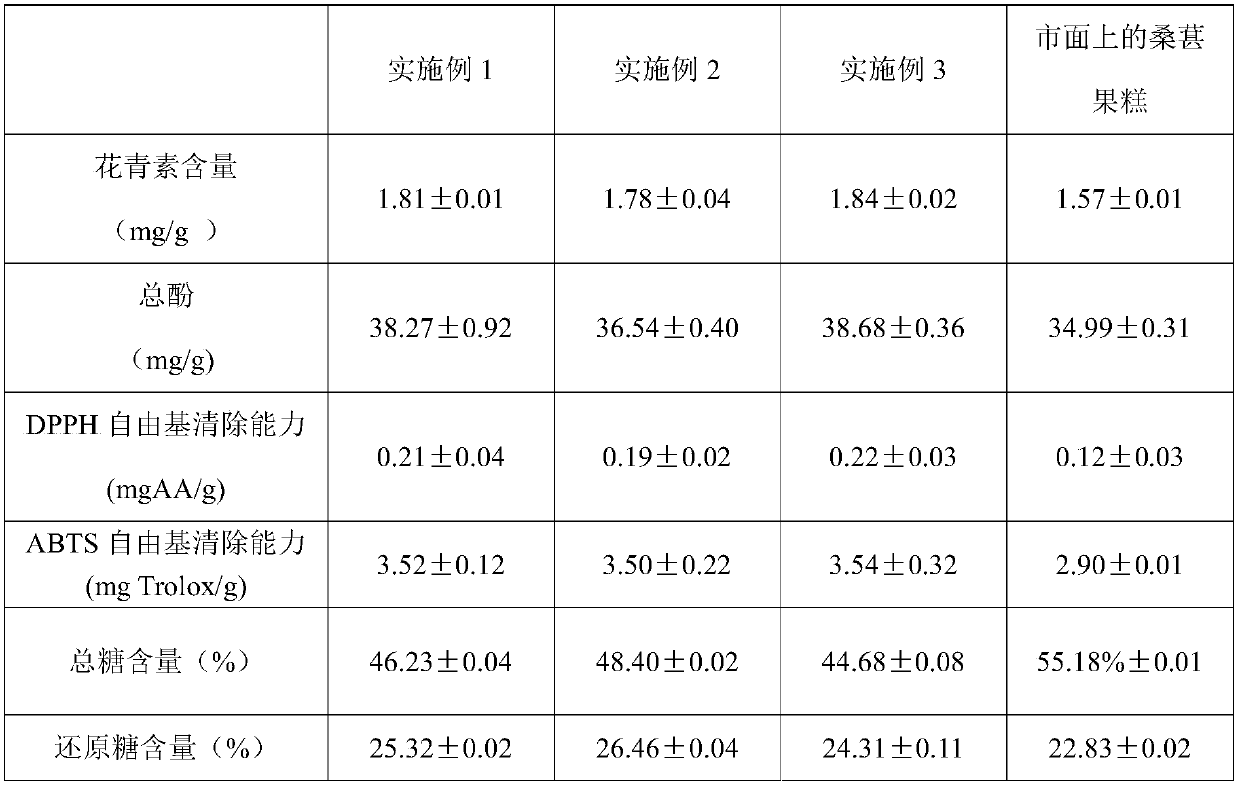

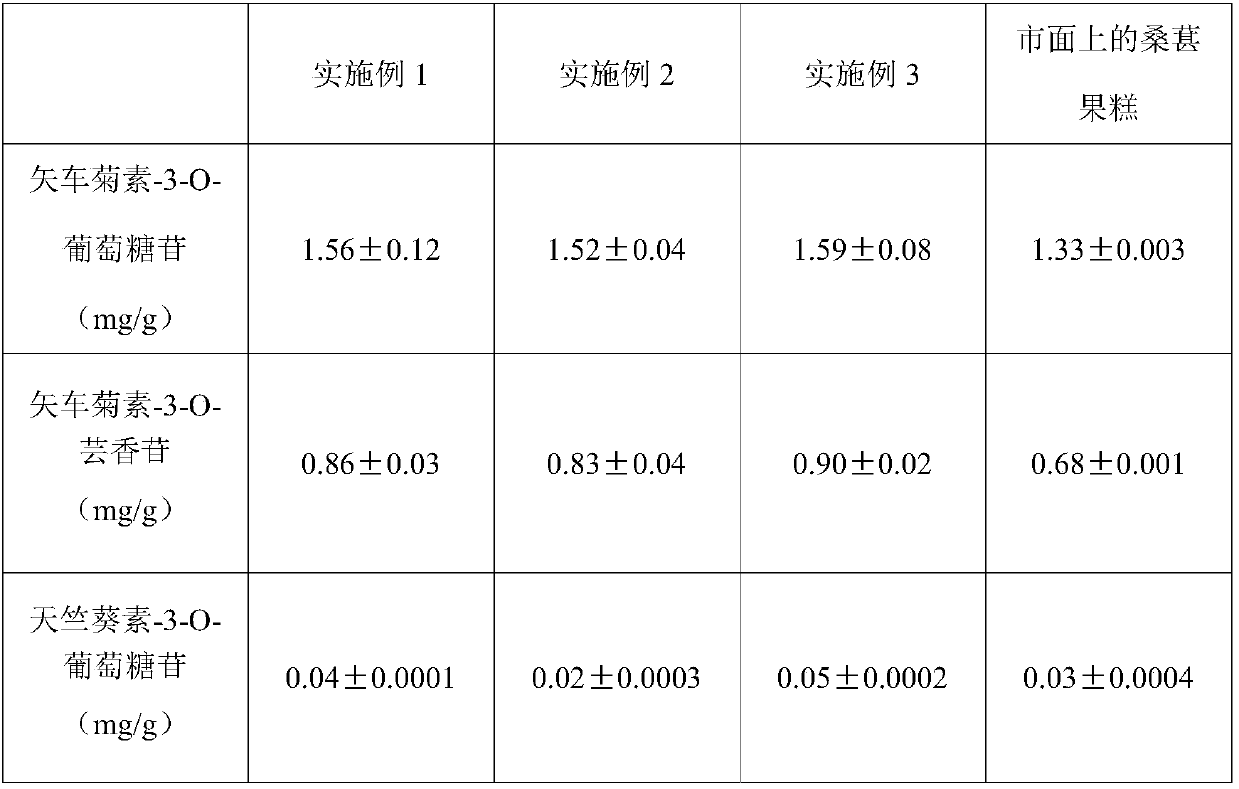

Examples

Embodiment 1

[0029] S1: Select fresh and mature mulberries, wash and drain;

[0030] S2: Use a colloid mill and a homogenizer to grind the drained mulberry into a pulp, so that the particle size of the pulp is below 20 μm;

[0031] S3: Heat and boil for 2 minutes to inactivate the enzymes of the ground fruit pulp, and then let it cool down;

[0032] S4: concentrating the fruit pulp after deactivating the enzyme into mulberry concentrated pulp with a water content of 75%;

[0033] S5: Mix and stir 70 parts of mulberry concentrated pulp and 18 parts of Luo Han Guo polysaccharide to make a semi-finished fruit pulp, dissolve 1.8 parts of xanthan gum and 1.5 parts of agar in warm water to prepare a composite gel, mix it with the semi-finished fruit pulp, add 1.5 parts of citric acid, 30 parts of maltodextrin and 0.7 parts of potassium sorbate are made into mulberry fruit cake mix;

[0034] S6: Boil the mulberry fruit cake mixture for 7 minutes, stir while cooking, pour and coat the plate at 7...

Embodiment 2

[0036] S1: Select fresh and mature mulberries, wash and drain;

[0037] S2: Use a colloid mill and a homogenizer to grind the drained mulberry into a pulp, so that the particle size of the pulp is below 20 μm;

[0038] S3: Heat and boil for 3 minutes to inactivate the enzymes of the ground fruit pulp, and then let it cool down;

[0039] S4: concentrating the fruit pulp after deactivating the enzyme into mulberry concentrated pulp with a water content of 80%;

[0040] S5: Mix 80 parts of mulberry concentrate and 25 parts of erythritol to make a semi-finished fruit pulp, dissolve 1.5 parts of xanthan gum and 1.3 parts of agar in warm water to prepare a composite gel, and mix it with the semi-finished fruit pulp , adding 2.0 parts of citric acid, 35 parts of maltodextrin and 0.5 part of potassium sorbate to make mulberry fruit cake mix;

[0041] S6: Boil the mulberry fruit cake mixture for 5 minutes, stir while cooking, pour and coat the plate at 80°C after boiling, the thickne...

Embodiment 3

[0043] S1: Select fresh and mature mulberries, wash and drain;

[0044] S2: Use a colloid mill and a homogenizer to grind the drained mulberry into a pulp, so that the particle size of the pulp is below 20 μm;

[0045] S3: Heat and boil for 2 minutes to inactivate the enzymes of the ground fruit pulp, and then let it cool down;

[0046] S4: concentrating the fruit pulp after deactivating the enzyme into a concentrated mulberry pulp with a water content of 70%;

[0047] S5: Mix and stir 75 parts of mulberry concentrate and 15 parts of erythritol to make a semi-finished fruit pulp, dissolve 2 parts of xanthan gum and 1.0 part of agar in warm water to prepare a composite gel, and mix it with the semi-finished fruit pulp , adding 1.7 parts of citric acid, 33 parts of maltodextrin and 1 part of potassium sorbate to make mulberry fruit cake mix;

[0048] S6: Boil the mulberry fruit cake mixture for 6 minutes, stir while cooking, pour and coat the plate at 70°C after boiling, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com