System and method for industrial-boiler flue-gas desulfurization and denitrification

A technology for desulfurization and denitrification, industrial boilers, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of high power consumption, high oxidation cost, small footprint, etc., to improve absorption efficiency and achieve regeneration. The effect of utilization, reduction of oxidation cost and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

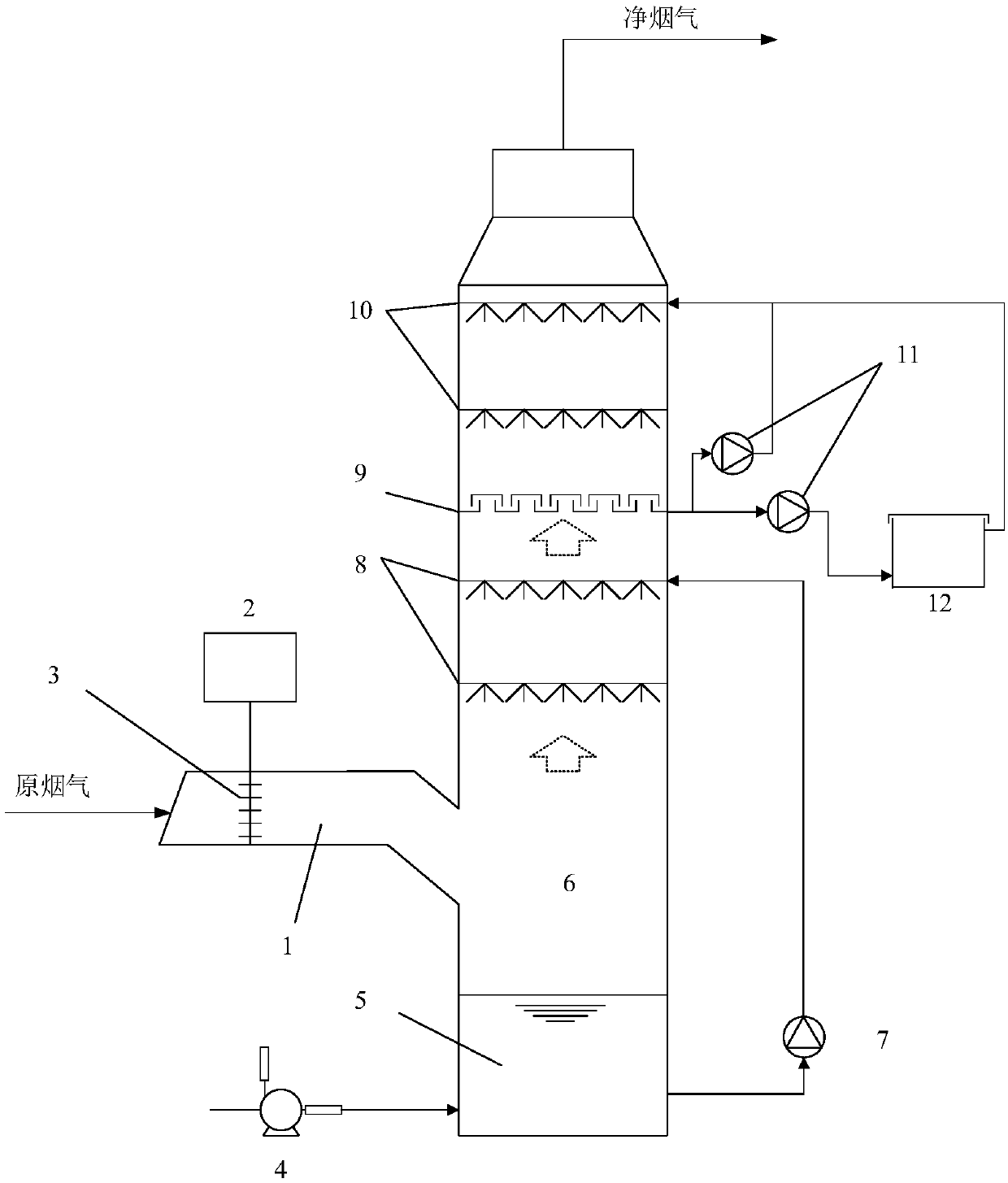

[0035] A kind of industrial boiler flue gas desulfurization and denitrification system of the present invention, such as figure 1 As shown, it includes a desulfurization slurry pool 5; a spray tower 6; an inlet flue 1 of the spray tower 6; a pre-oxidation system 2; an oxidant injection that is connected to the pre-oxidation system 2 and is arranged in the inlet flue 1 for two-way injection System 3; oxidation blower 4, which is used to blow fresh air into the desulfurization slurry pool 5 to forcibly oxidize sulfite to sulfate; desulfurization circulation pump 7; desulfurization spray layer 8, two layers of spray are set in this preferred example To ensure the desulfurization efficiency; the gas-liquid separation layer 9 is used to isolate the desulfurization cycle and the denitration cycle, to ensure the flue gas circulation, and to prevent the denitrification slurry from mixing into the desulfurization cycle area below; the denitrification spray layer 10 is used for double-la...

Embodiment 2

[0043] The present invention is an industrial boiler flue gas desulfurization and denitrification system. The pre-oxidation system 2 and the oxidant injection system 3 respectively use an ozone generator and an ozone injection system. First, the ozone generated by the ozone generator is sprayed into the spray tower 6 by the ozone injection system. The inlet flue 1 of the flue gas oxidizes NO in the flue gas to NO 2 , the flue gas enters the spray tower 6 from the inlet flue 1 of the spray tower 6, and the SO in the flue gas is removed by the limestone gypsum method or the ammonia method 2 , two or more layers of desulfurization spray layer 8 spray to ensure desulfurization efficiency, flue gas enters the denitrification circulation system through the gas-liquid separation layer 9 after desulfurization, under the spraying action of the denitrification spray layer 10 NO 2 Absorbed by the catalyst to form oxidative substances; the denitrification slurry containing oxidative subs...

Embodiment 3

[0047] A kind of method of industrial boiler flue gas desulfurization and denitrification of the present invention comprises the following steps:

[0048] Step 1, pre-oxidation: use the pre-oxidation system 2 to spray an oxidant into the inlet flue 1 of the spray tower 6 to oxidize NO in the flue gas to low-valence NO 2 , the treated flue gas enters the spray tower 6;

[0049] Step 2, desulfurization treatment: the sulfur oxides in the treated flue gas are absorbed in the desulfurization circulation system by the alkaline water-soluble absorbent sprayed by the desulfurization spray layer 8, that is, the desulfurization slurry, to generate sulfite / sulfate; after desulfurization The flue gas rises into the denitrification circulation system after passing through the gas-liquid separation layer 9 such as the liquid holding layer;

[0050] Step 3, denitration treatment: the nitrogen oxides in the flue gas after desulfurization are absorbed by the organic catalyst sprayed on the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com