Method for biological ex-situ degradation of formaldehyde

A formaldehyde and ectopic technology, which is applied in the field of ectopic biodegradation of volatile organic pollutants, can solve the problems of cumbersome steps, large quantities, and many varieties, and achieve simple and convenient operation, low energy consumption, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Based on the method of microbial in-situ degradation of formaldehyde, in-situ biodegradation of formaldehyde is carried out in two ways, one is a microbial suspension growth system, and the other is a biofilm system. The steps are as follows:

[0066] 1) Suspension growth system is to take the sewage from the sewage treatment plant as the source of microorganisms, and add the nutrients required by the microorganisms [sodium acetate 1.0g L -1 , phosphate buffer (50mM PBS, NH 4 Cl 0.31g L -1 ,KCl 0.13g·L -1 ,NaH 2 PO 4 2H 2 O 2.772g·L -1 , Na 2 HPO 4 4.576g·L -1 ), metal solution 12.5mL·L -1 , and vitamin solution 5mL·L -1 ], expose oxygen to the solution for 10min, add high-concentration formaldehyde solution to make the concentration respectively 6, 8, 10 and 20mg / L, seal with tinfoil paper and plastic wrap, and treat for 24h.

[0067] 2) The biofilm system is also the sewage from the sewage treatment plant as the source of the carbon cloth to enrich the mic...

Embodiment 2

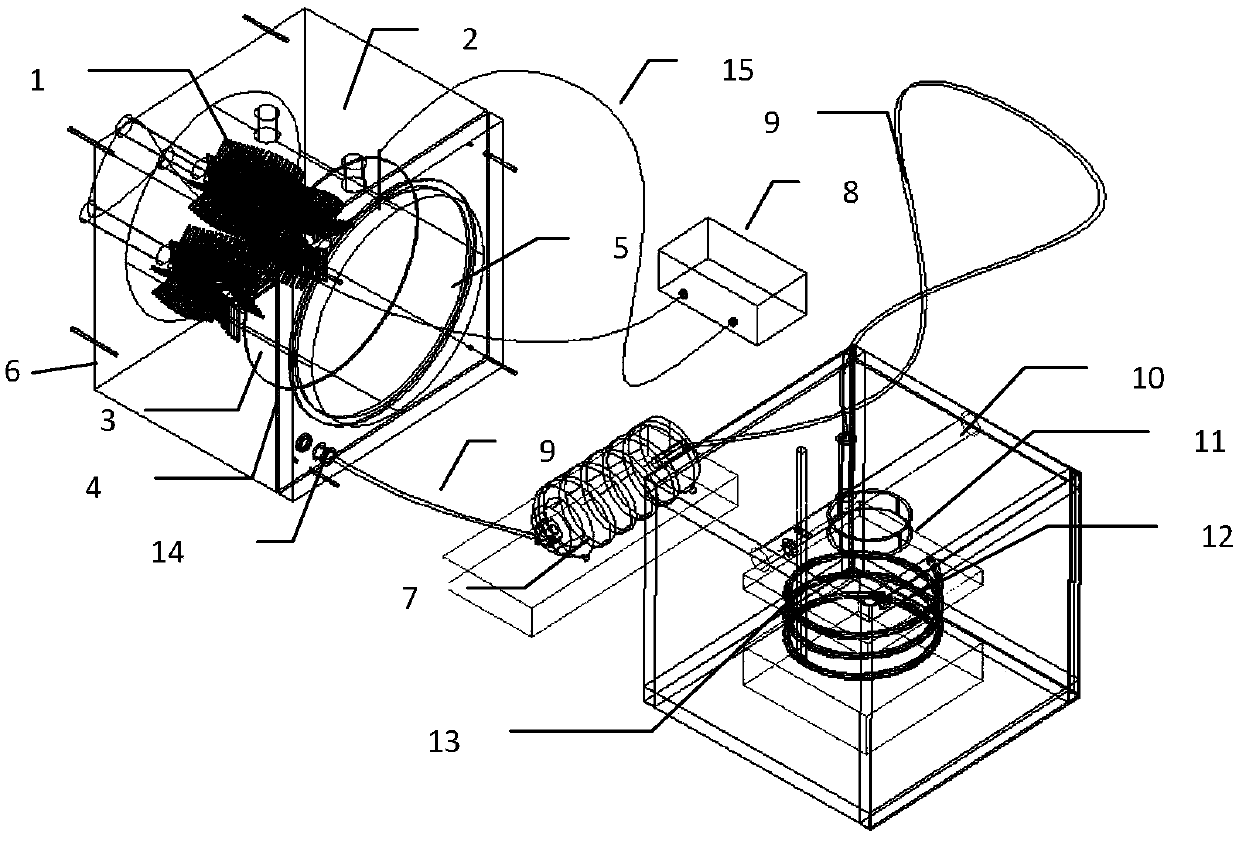

[0070] Synthesis of H based on microbial electrochemical system 2 o 2 And realize the biological heterotopic degradation formaldehyde method, the steps of the present invention are as follows:

[0071] 1) Install the graphite-carbon black mixed roll-pressed air cathode into the cathode chamber of an anode-acclimated microbial electrochemical system. The two chambers are separated by a cation exchange membrane to form a double-chamber BES. The cathode chamber is 50mM Na 2 SO 4 Solution, cultivated for two cycles to adapt the anode organisms to the environment.

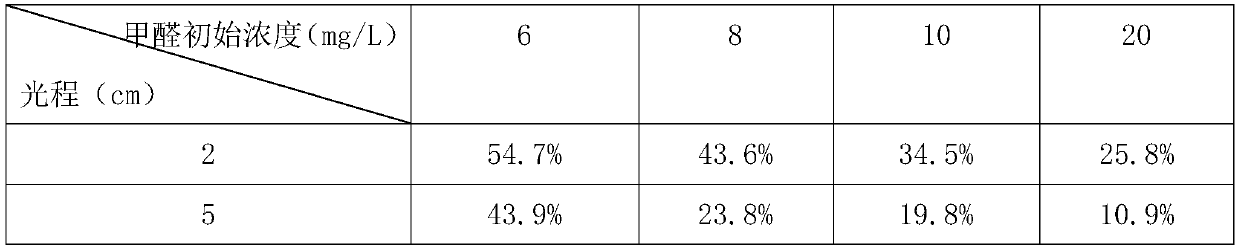

[0072] 2) Apply a bias voltage of 0.6V between the cathode and anode for 1h, and pump the accumulated H in the cathode chamber 2 o 2 Solution transfer to UV / H 2 o 2 In the reaction vessel, add high-concentration formaldehyde solution dropwise to make the concentrations 6mg / L, 8mg / L, 10mg / L and 20mg / L respectively, adjust the pH of the solution to 3, set the optical path to 2cm and 5cm, turn on the stirrer and Low-p...

Embodiment 3

[0077] Synthesis of H based on microbial electrochemical system 2 o 2 And realize the method for biological heterotopic degradation of formaldehyde, the steps are as follows:

[0078] 1) Install the graphite-carbon black mixed roll-pressed air cathode into the cathode chamber of an anode-acclimated microbial electrochemical system. The two chambers are separated by a cation exchange membrane to form a double-chamber BES. The cathode chamber is 50mM Na 2 SO 4 Solution, cultivated for two cycles to adapt the anode organisms to the environment.

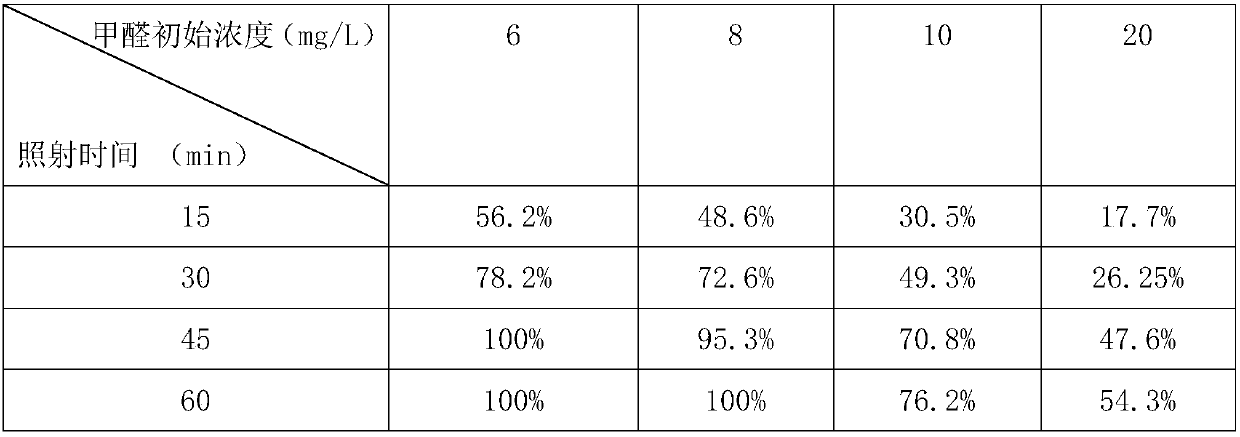

[0079] 2) Apply 0.6V bias voltage 0h, 0.5h, 1.0h and 1.5h between the cathode and anode, and use the pump to transfer the hydrogen peroxide solution accumulated in the cathode chamber for 0h, 0.5h, 1.0h and 1.5h to the UV / h 2 o 2 In the reaction vessel, add high-concentration formaldehyde solution dropwise to make the concentration 6mg / L, adjust the pH of the solution to 3, set the optical path to 2cm, turn on the stirrer and low-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com