Hollow-structure CuCeOx bimetallic oxide catalyst and preparation method thereof

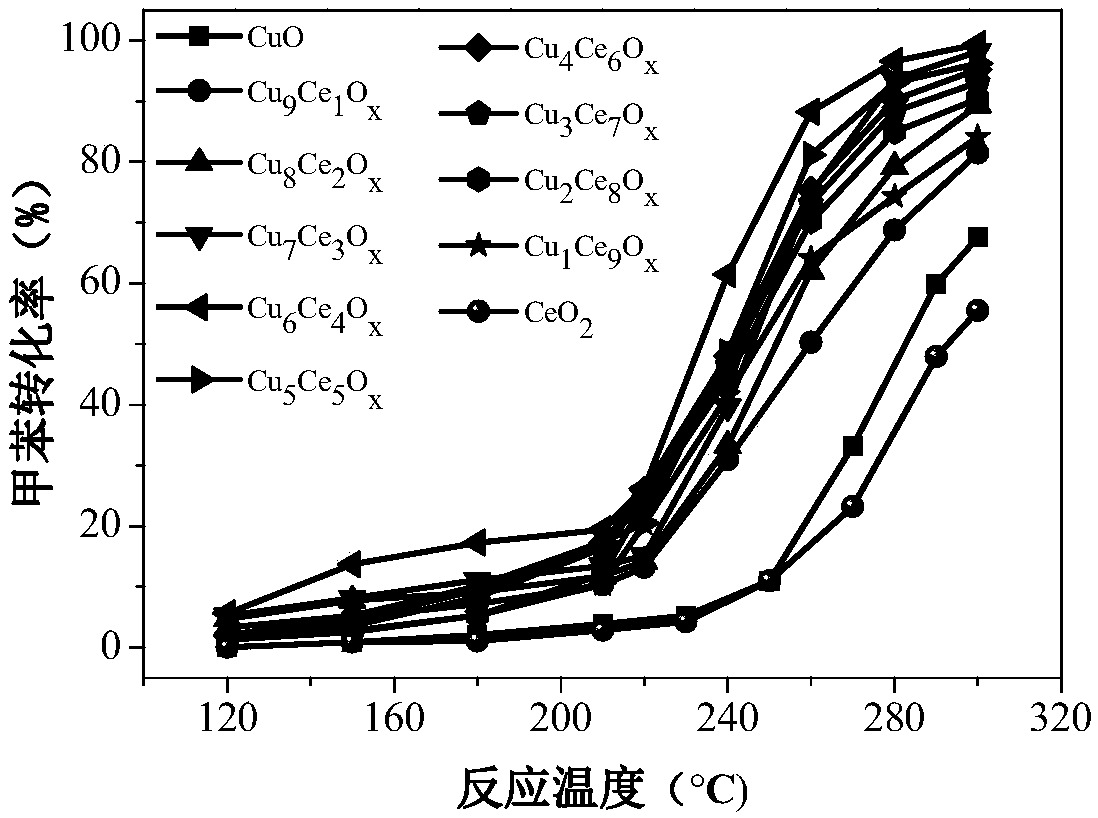

A bimetallic oxide, hollow structure technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of poor uniformity of the control hollow structure and many influencing factors , poor controllability and other problems, to achieve the effect of superior catalytic activity, high controllability and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Take 1.0g CuSO respectively 4 ·5H 2 O. Dissolve 4.0g of glucose in 30mL of deionized water, transfer to a 50mL hydrothermal kettle and heat to 160°C, keep for 36h, then cool to room temperature, wash and dry with deionized water several times, and then carbon-assisted CuO metal oxidation can be obtained. material precursor; then placed in a muffle furnace and baked at 550°C for 4h to obtain hollow CuO microspheres.

Embodiment 2

[0030] Take 0.8g Ce(NO 3 ) 3 ·6H 2 O. Dissolve 3.6g of glucose in 30mL of deionized water, transfer to a 50mL hydrothermal kettle and heat to 180°C, keep it for 24h, then cool to room temperature, wash with deionized water several times, and dry to obtain carbon-assisted CeO 2 Metal oxide precursor; then placed in a muffle furnace and baked at 550 ° C for 4 hours to obtain a hollow structure CeO 2 Microspheres.

Embodiment 3

[0032] Take 0.33g Ce(NO 3 ) 3 ·6H 2 O, 0.275g Cu(NO 3 ) 2 ·3H 2 O. Dissolve 4.0g of glucose in 30mL of deionized water, transfer to a 50mL hydrothermal kettle and heat to 180°C, keep for 24h and then cool to room temperature, wash and dry with deionized water several times to obtain carbon-assisted CuCeO x Double metal oxide precursor; then placed in a muffle furnace at 550 ° C for 4 hours to obtain a hollow structure Cu 6 Ce 4 o x Microspheres.

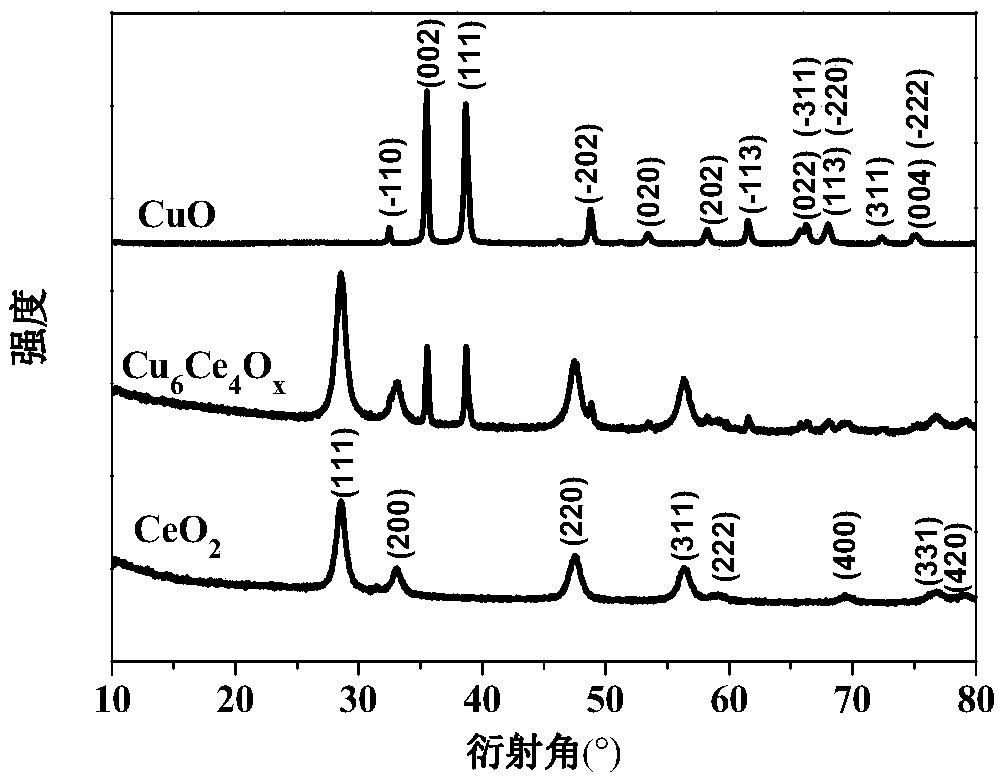

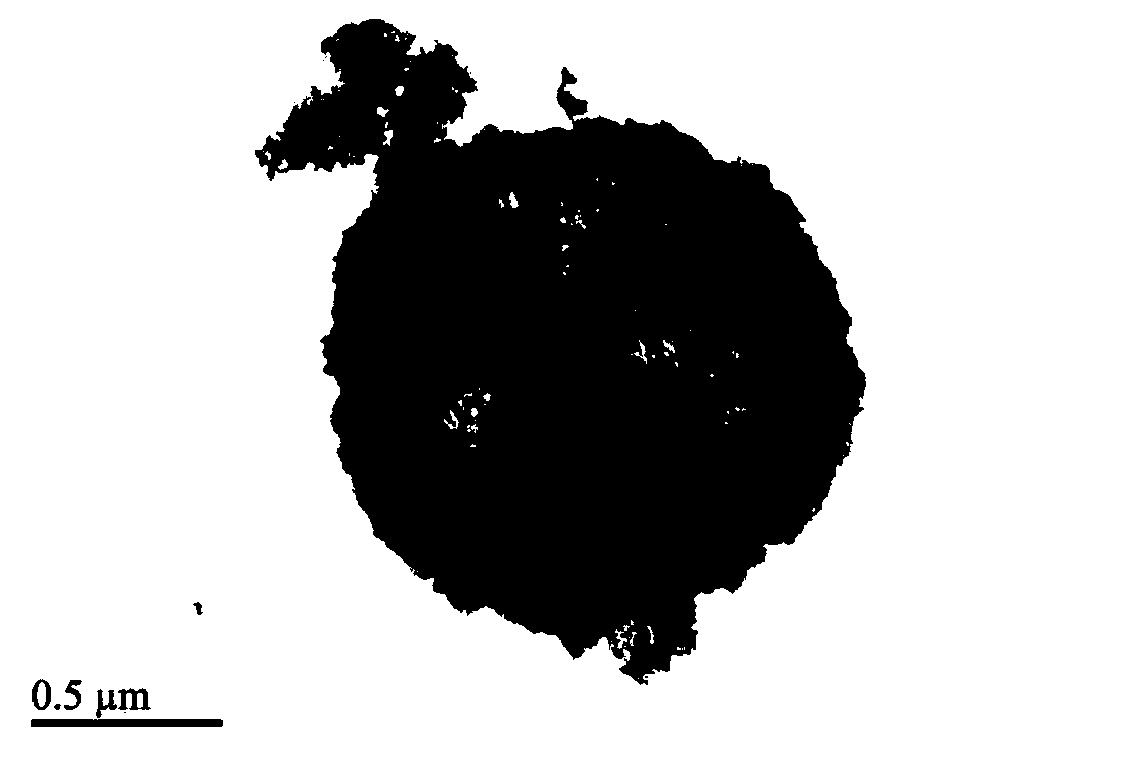

[0033] figure 1 The X-ray diffraction patterns of Examples 1-3 are given. It can be seen that the obvious CuO (JPCDS: 00-045-0937) and CeO 2 (JPCDS: 03-065-2975), hollow structure Cu 6 Ce 4 o x Microspheres also exhibit corresponding diffraction characteristic peaks. Further to the hollow structure Cu 6 Ce 4 o x Microspheres were characterized by transmission electron microscopy, and it can be seen that there are obvious micron-scale hollow structures ( figure 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com