Single crystal silicon carbide green and efficient polishing tool and method for polishing single crystal silicon carbide

A single crystal silicon carbide and polishing grinding technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, grinding machines, etc., can solve the problem of high processing costs, poor environmental friendliness in the polishing process, and is not suitable for batch polishing of silicon carbide single crystals Processing requirements and other issues, to achieve the effect of low processing cost and high-efficiency polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

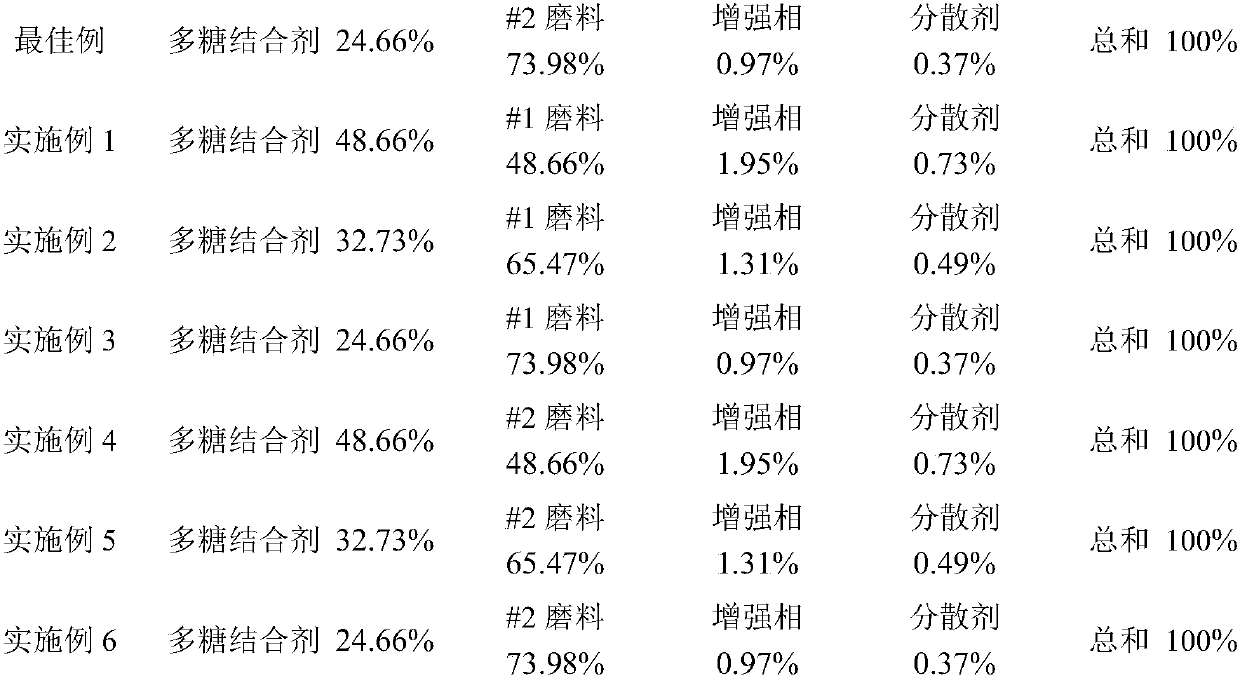

[0044] Single crystal silicon carbide green, high-efficiency polishing abrasive formula:

[0045] Polysaccharide binder: 5g of raw corn starch;

[0046] Abrasive: W5 single crystal aluminum oxide 5g;

[0047] Reinforcement phase: microcrystalline cellulose 0.2g;

[0048] Dispersant: guar gum 0.075g.

[0049] The manufacturing process of single crystal silicon carbide green and high-efficiency polishing abrasive tools:

[0050] (1) Mixture:

[0051] First, weigh the polysaccharide binder, single crystal aluminum oxide abrasive, and reinforcing phase material powders that meet the ratio requirements and mix them into a dry beaker, and use a stirring rod to mix the three powders. Measure guar gum and a certain amount of water and stir to form a guar gum solution. Stir the aforementioned mixed powder and guar gum solution until evenly mixed.

[0052] (2) Curing:

[0053] Pour the mixture into the mold and bake at 130°C for 75min. After the baking is finished, the semi-soli...

Embodiment 2

[0061] Single crystal silicon carbide green, high-efficiency polishing abrasive formula:

[0062] Polysaccharide binder: 5g of raw corn starch;

[0063] #1 Abrasive: W40 single crystal aluminum oxide 10g;

[0064] Reinforcement phase: lignocellulose 0.2g;

[0065] Dispersant: refined carrageenan 0.075g.

[0066] The manufacturing process of single crystal silicon carbide green and high-efficiency polishing abrasive tools:

[0067] (1) Mixture:

[0068] First, weigh the polysaccharide binder, single crystal aluminum oxide abrasive, and reinforcing phase material powders that meet the ratio requirements and mix them into a dry beaker, and use a stirring rod to mix the three powders. Measure refined carrageenan and a certain amount of water and stir to form a guar gum solution. Stir the aforementioned mixed powder and refined carrageenan solution until evenly mixed.

[0069] (2) Curing:

[0070] Pour the mixture into the mold and bake at 160°C for 100min. After the baking...

Embodiment 3

[0078] Single crystal silicon carbide green, high-efficiency polishing abrasive formula:

[0079] Polysaccharide binder: 5g of raw corn starch;

[0080] #1 Abrasive: W5 single crystal aluminum oxide 15g;

[0081] Reinforcement phase: microcrystalline cellulose 0.2g;

[0082] Dispersant: guar gum 0.075g.

[0083] The manufacturing process of single crystal silicon carbide green and high-efficiency polishing abrasive tools:

[0084] (1) Mixture:

[0085] First, weigh the polysaccharide binder, single crystal aluminum oxide abrasive, and reinforcing phase material powders that meet the ratio requirements and mix them into a dry beaker, and use a stirring rod to mix the three powders. Measure guar gum and a certain amount of water and stir to form a guar gum solution. Stir the aforementioned mixed powder and guar gum solution until evenly mixed.

[0086] (2) Curing:

[0087] Pour the mixture into the mold and bake at 150°C for 90min. After the baking is finished, the semi-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com