Nano tungsten doped tin dioxide powder and preparation method thereof

A technology of tin dioxide and nano-tungsten, which is applied in the field of nano-materials, can solve the problems of low visible light transmittance and poor heat insulation of powder, and achieve good dispersion, good thermal stability and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Dissolve tin tetrachloride and ammonium metatungstate in deionized water to prepare a precursor with a concentration of 0.01mol / L, and the molar ratio of ammonium metatungstate to tin tetrachloride is 1:100;

[0020] (2) Pour the precursor into an ultrasonic atomizer for atomization, using air as the carrier gas, and the carrier gas passes the atomized droplets into a tube furnace for pyrolysis at 200 °C;

[0021] (3) Collect tungsten-doped tin dioxide powder with deionized water, and dry the collected powder at 50°C;

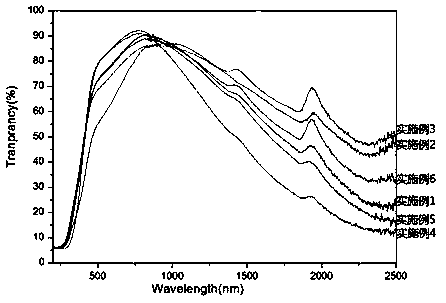

[0022] (4) Anneal the dried powder at 200°C for 10 hours, and then prepare nano-tungsten-doped tin dioxide powder after cooling. The UV-visible-infrared light transmittance spectrum curve of the powder is shown in image 3 , it can be seen from the figure that the transmittance of visible light is 70%-90%, and the transmittance of some visible light bands can reach 90%, while the transmittance of near infrared can also be kept at a low value.

Embodiment 2

[0024] (1) Dissolve tin tetrachloride and ammonium metatungstate in deionized water to prepare a precursor with a concentration of 0.15mol / L, and the molar ratio of ammonium metatungstate to tin tetrachloride is 5:100;

[0025] (2) Pour the precursor into an ultrasonic atomizer for atomization, using air as the carrier gas, and the carrier gas passes the atomized droplets into a tube furnace for pyrolysis at 600 °C;

[0026] (3) Collect tungsten-doped tin dioxide powder with deionized water, and dry the collected powder at 50°C;

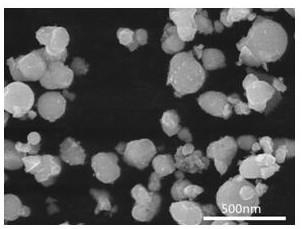

[0027] (4) The dried powder was annealed at 600°C for 3 hours, and the nano-tungsten-doped tin dioxide powder was obtained after cooling. The scanning electron microscope (SEM) picture of the powder is shown in figure 2 , it can be seen from the figure that it is a nano-spherical powder, and the UV-visible-infrared light transmittance spectrum curve of the powder is shown in image 3 , it can be seen from the figure that the transmittance of visibl...

Embodiment 3

[0029] (1) Dissolve tin tetrachloride and ammonium metatungstate in deionized water to prepare a precursor with a concentration of 1.5mol / L, and the molar ratio of ammonium metatungstate to tin tetrachloride is 40:100;

[0030] (2) Pour the precursor into an ultrasonic atomizer for atomization, using air as the carrier gas, and the carrier gas passes the atomized droplets into a tube furnace for pyrolysis at 700 °C;

[0031] (3) Collect tungsten-doped tin dioxide powder with deionized water, and dry the collected powder at 50°C;

[0032] (4) Anneal the dried powder at 1000°C for 1 hour, and prepare nano-tungsten-doped tin dioxide powder after cooling. The UV-visible-infrared light transmittance spectrum curve of the powder is shown in image 3 , it can be seen from the figure that the transmittance of visible light is 70%-90%, and the transmittance of near infrared can also be kept at a low value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com