Natural rubber processing wastewater deep biological denitrogenation apparatus and method

A technology for processing waste water and natural rubber, applied in chemical instruments and methods, waste fuel, water pollutants, etc., can solve the problem of high energy consumption of activated sludge aeration process, odor affecting the living environment of residents, and increasing operating costs of enterprises, etc. problem, to achieve the effect of saving carbon source, reducing output, and saving carbon source addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

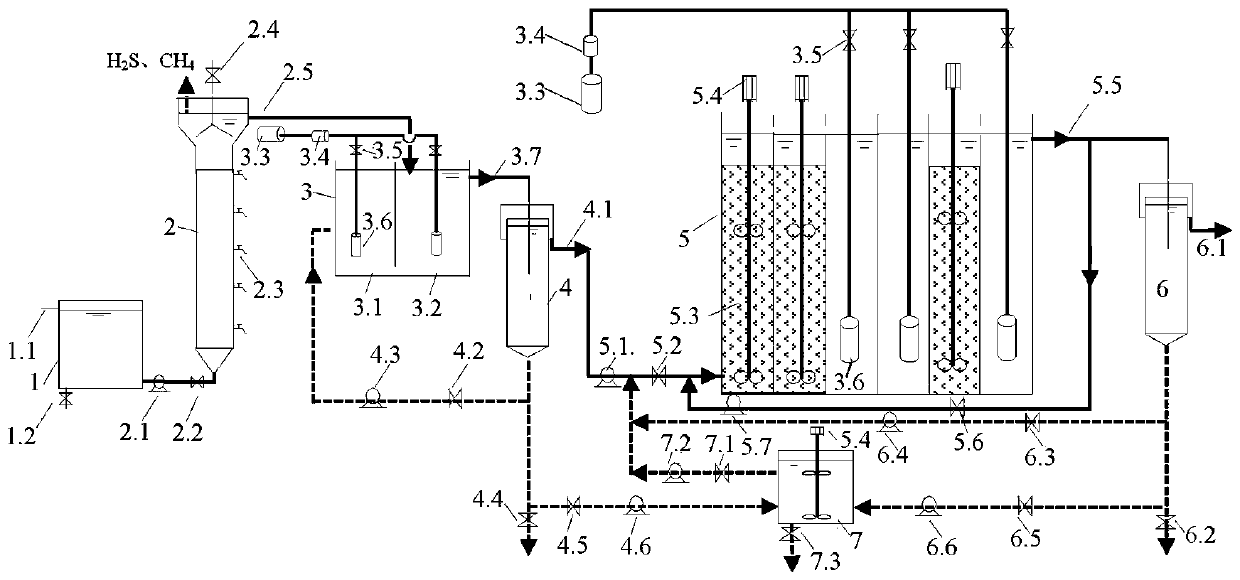

[0028] Below in conjunction with accompanying drawing and embodiment the present invention will be further described: as figure 1 As shown, the denitrification device for treating natural rubber processing wastewater is equipped with a waste water tank 1, anaerobic methanogenesis reactor 2, organic matter removal reactor 3, 1# sedimentation tank 4, AOAO reactor 5, 2# sedimentation tank 6, production Acid pool 7; waste water tank 1 is provided with overflow pipe 1.1 and vent pipe 1.2; waste water tank 1 passes through anaerobic methanation reactor water inlet pump 2.1 and anaerobic methanation reactor water inlet valve 2.2 and anaerobic methanation reactor 2-phase connection, the anaerobic methanogenic reactor 2 is columnar, with a three-phase separator 2.4 at the top, and the top discharges H 2 S and CH 4 , the side is provided with a sampling port 2.3; the oxygen methanogenesis reactor 2 is connected with the organic matter removal reactor 3 through the oxygen methanogenesis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com