Nano color wall decoration mortar

A finishing mortar and nano-technology, applied in the field of nano-colored wall finishing mortar, can solve the problem of single decoration function, achieve strong weather resistance, enhance and improve human immunity, and purify the indoor environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

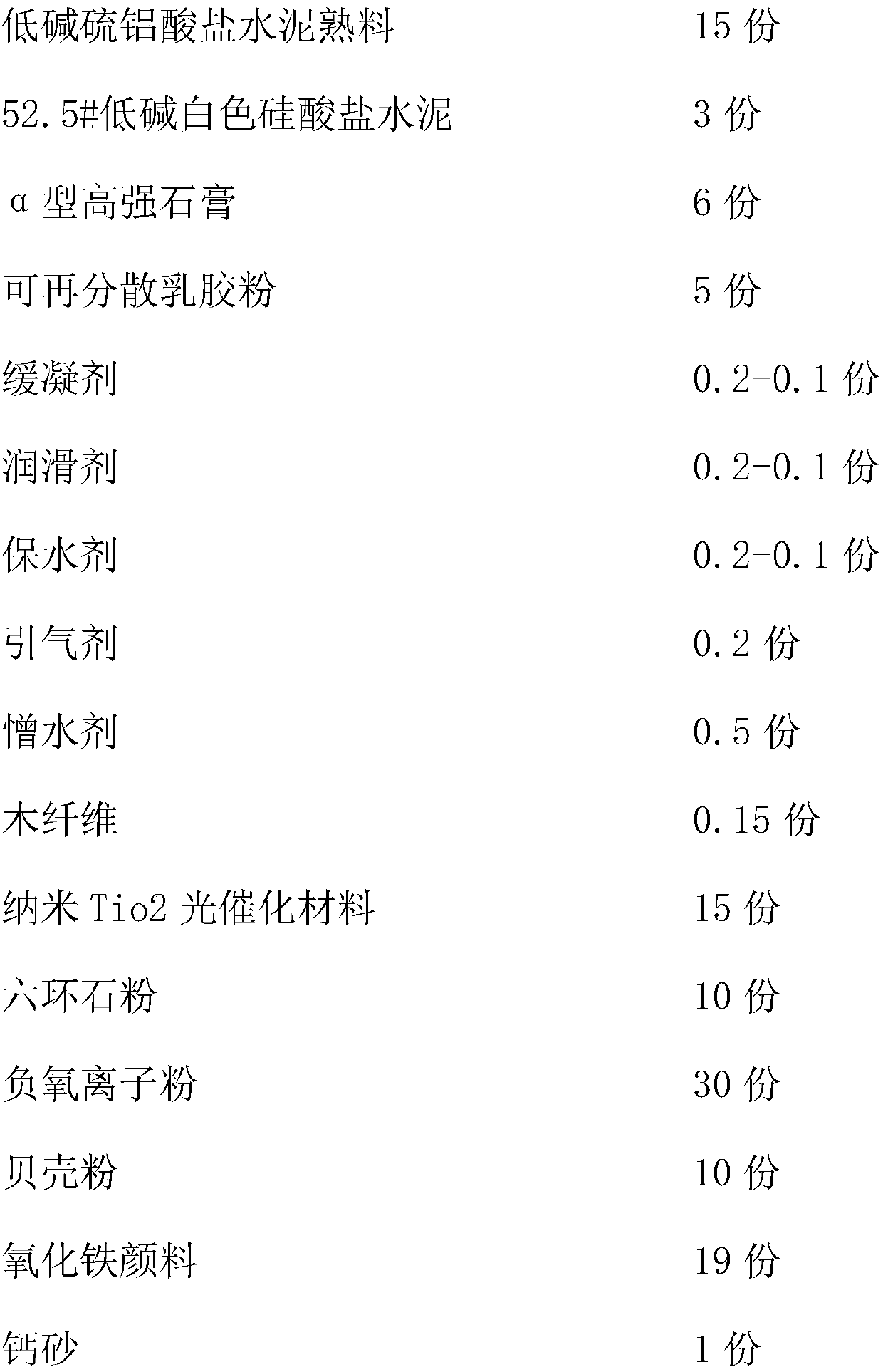

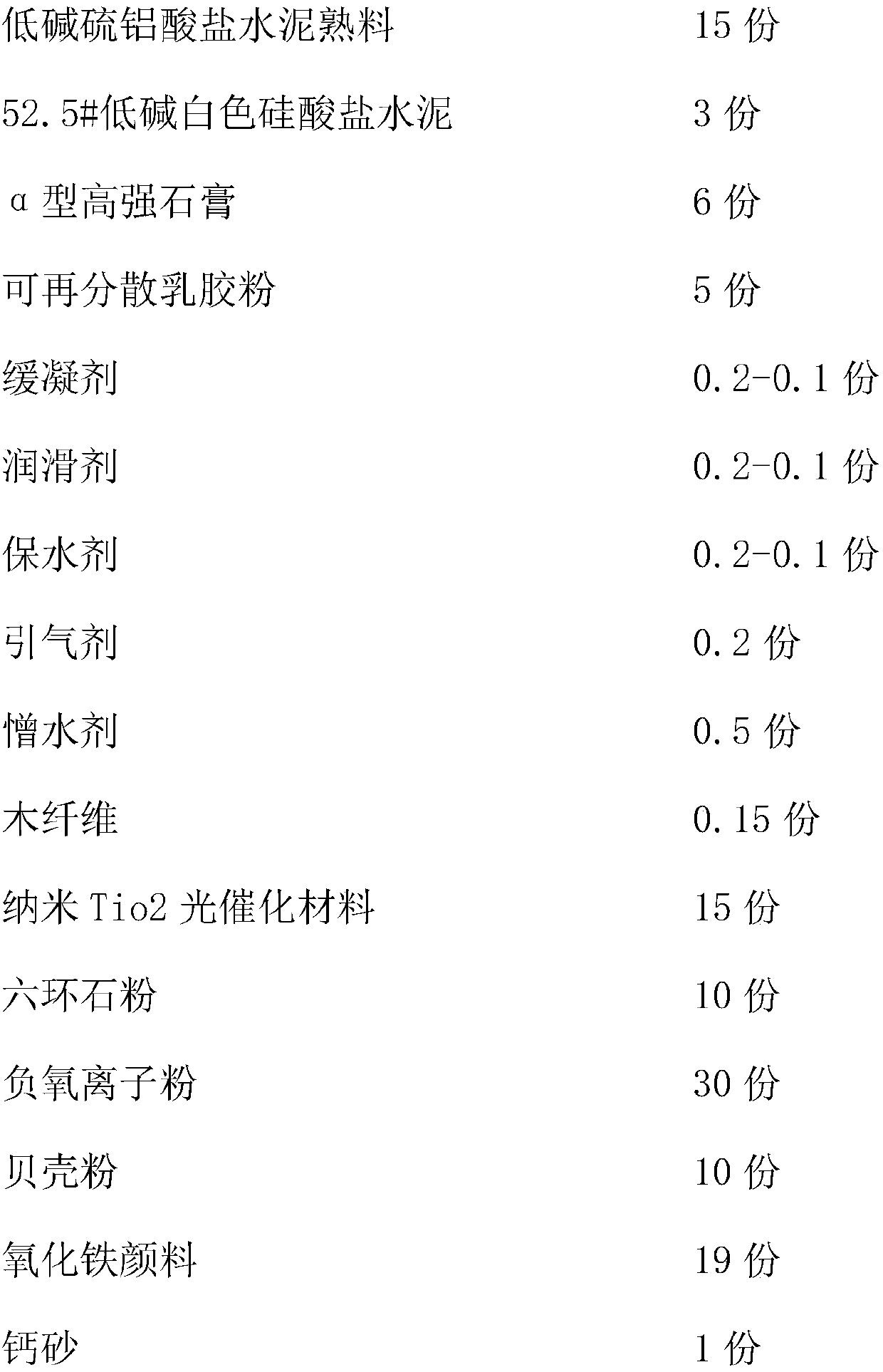

[0018] Nano-colored wall facing mortar, its preparation method, application formula from March to June, first add 19 parts of calcium sand, 1 part of iron oxide pigment, mix for 5 minutes, then add 15 parts of low-alkali sulfoaluminate cement clinker in sequence 3 parts, 52.5# low-alkali white Portland cement 3 parts, a-type high-strength gypsum 6 parts, redispersible latex powder 5 parts, retarder 0.2 parts, lubricant 0.2 parts, water-retaining agent 0.2 parts, water-repellent agent 0.2 parts , 0.5 parts of wood fiber, 0.15 parts of air-entraining agent, 15 parts of nano-Tio2 photocatalytic material, 10 parts of hexacyclic stone powder, 30 parts of shell powder, and 10 parts of negative oxygen ion powder. After adding all the raw materials, mix for 20 minutes and take a sample. The uniformly mixed mixture is made into a sample, and the color and style are compared with the sample provided by the customer. After meeting the requirements of the customer's sample, the routine per...

Embodiment 2

[0020] Nano-color wall finish mortar, its preparation method, application formula from June to September, first add 19 parts of calcium sand, 1 part of iron oxide pigment, mix for 5 minutes, then add 15 parts of low-alkali sulfoaluminate cement clinker in sequence 52.5# low-alkali white Portland cement 3 parts, a-type high-strength gypsum 6 parts, redispersible latex powder 5 parts, retarder 0.15 parts, lubricant 0.15 parts, water-retaining agent 0.15 parts, water-repellent agent 0.2 parts , 0.5 parts of wood fiber, 0.15 parts of air-entraining agent, 15 parts of nano-Tio2 photocatalytic material, 10 parts of hexacyclic stone powder, 30 parts of shell powder, and 10 parts of negative oxygen ion powder. After adding all the raw materials, mix for 20 minutes and take a sample. The uniformly mixed mixture is made into a sample, and the color and style are compared with the sample provided by the customer. After meeting the requirements of the customer's sample, the routine perform...

Embodiment 3

[0022] Nano-color wall facing mortar, its preparation method, first add 19 parts of calcium sand, 1 part of iron oxide pigment, mix for 5 minutes, then add 15 parts of low-alkali sulfoaluminate cement clinker, 52.5# low-alkali white silicon 3 parts salt cement, 6 parts A-type high-strength gypsum, 5 parts redispersible latex powder, 0.1 part retarder, 0.1 part lubricant, 0.1 part water-retaining agent, 0.2 part water-repellent agent, 0.5 part wood fiber, air-entraining 0.15 parts of nanometer Tio2 photocatalytic material, 10 parts of hexacyclic stone powder, 30 parts of shell powder, and 10 parts of negative oxygen ion powder. After adding all the raw materials, mix them for 20 minutes and take samples. Sample, compare the color and style with the sample provided by the customer, and then carry out routine performance testing after meeting the requirements of the customer sample, and then pack it into bags.

[0023] The inorganic properties of the present invention based on na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com