Preparing method of calcium ferrite/calcium titanate diffusion couple

A technology of calcium ferrite and calcium titanate, which is applied in the field of material research, can solve the problems of unknown physical and chemical properties of calcium ferrite and calcium titanate, and achieve the effects of high density, narrow diffusion and mixing transition area, and smooth interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

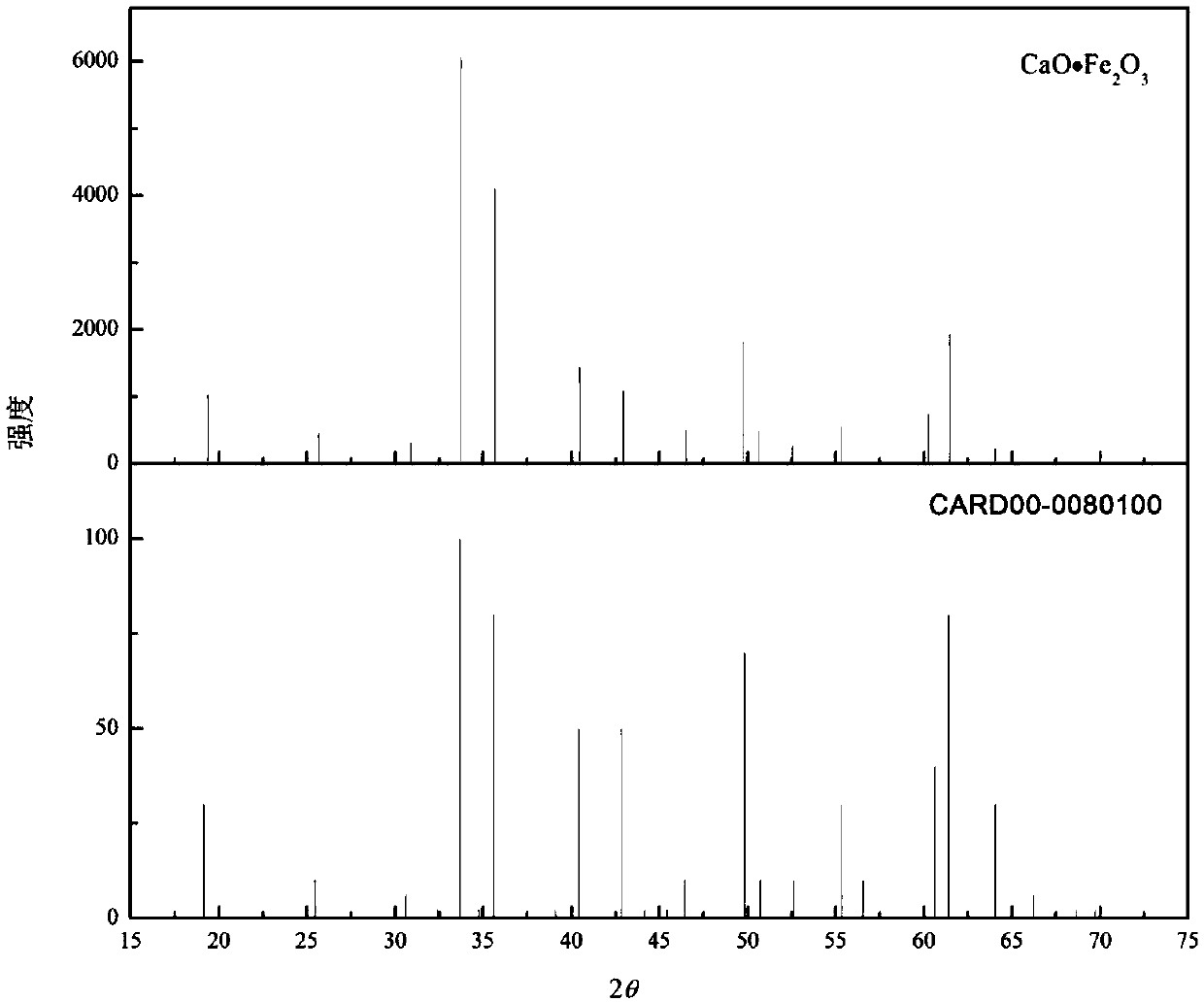

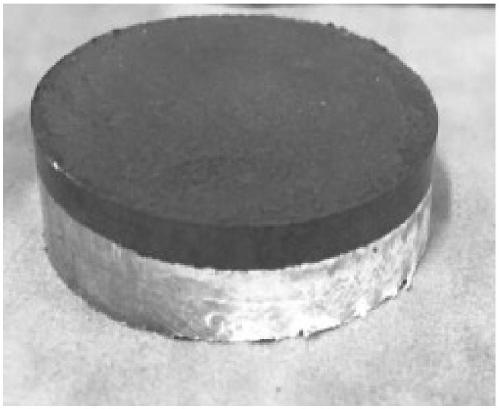

[0033] S1, the Fe 2 o 3 The powder and CaO powder are mixed according to the ratio of 1:1.3 and packed in a cylindrical airtight plastic cylinder. Put the cylinder into a mixer and mix for 5 hours to make the two powders mix evenly. After mixing, put the mixed powder in a mortar, stir and grind evenly, then put the mixed powder into a stainless steel mold with an inner diameter of 30mm with a medicine spoon, and press the mixed powder into a consolidated tablet with a tablet machine , the pressure is 10MPa, and the pressure time is 5min. Place the obtained flakes on a corundum vessel, put them into a muffle furnace, raise the temperature to 1100°C at a rate of 10°C / min, keep it warm for 8 hours, and then air-cool to room temperature to obtain the following: figure 1 The calcium ferrite sheet (sample) shown is composed of figure 1 It can be seen that Fe 2 o 3 And CaO has formed a whole, reached the reaction temperature of calcium ferrite formation. figure 2 for will fig...

Embodiment 2

[0041] S1, the Fe 2 o 3The powder and CaO powder are mixed according to the ratio of 1:1.1 and packed in a cylindrical airtight plastic cylinder. Put the cylinder into a mixer and mix for 5 hours to make the two powders mix evenly. After mixing, put the mixed powder in a mortar, stir and grind evenly, then put the mixed powder into a stainless steel mold with an inner diameter of 30mm with a medicine spoon, and press the mixed powder into a consolidated tablet with a tablet machine , the pressure is 10MPa, and the pressure time is 7min. Place the obtained flakes on a corundum vessel, put them into a muffle furnace, raise the temperature to 1080°C at a heating rate of 10°C / min, keep it warm for 8 hours, and then air cool to room temperature to obtain calcium ferrite flakes.

[0042] S2. Put the calcium ferrite flakes in a mortar, crush and grind them to obtain calcium ferrite powder, mix the calcium ferrite powder with dilute hydrochloric acid and place them in a constant tem...

Embodiment 3

[0048] S1, the Fe 2 o 3 The powder and CaO powder are mixed in a cylindrical airtight plastic cylinder according to the ratio of the amount of the substance at 1:1.5, and the cylinder is put into a mixer and mixed for 5 hours to make the two powders mix evenly. After mixing, put the mixed powder in a mortar, stir and grind evenly, then put the mixed powder into a stainless steel mold with an inner diameter of 30mm with a medicine spoon, and press the mixed powder into a consolidated tablet with a tablet machine , the pressure is 11MPa, and the pressure time is 6min. Place the obtained flakes on a corundum vessel, put them into a muffle furnace, raise the temperature to 1120°C at a heating rate of 10°C / min, keep it warm for 10h, and then air-cool to room temperature to obtain calcium ferrite flakes.

[0049] S2. Put the calcium ferrite flakes in a mortar, crush and grind them to obtain calcium ferrite powder, mix the calcium ferrite powder with dilute hydrochloric acid and pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com