Crude benzene catalytic hydrogenation process and equipment

A technology for catalytic hydrogenation and crude benzene, applied in the field of coal chemical industry, can solve problems such as short service life of catalysts, achieve long service life, avoid waste, and alleviate the effects of coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

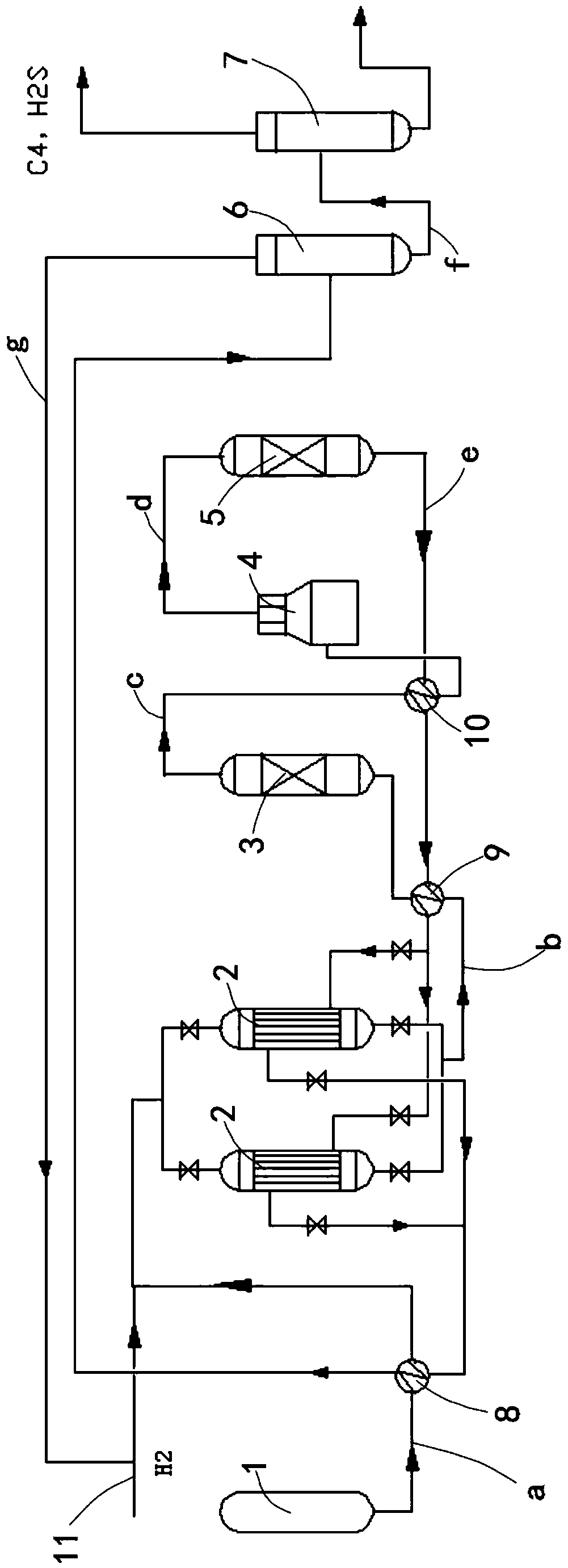

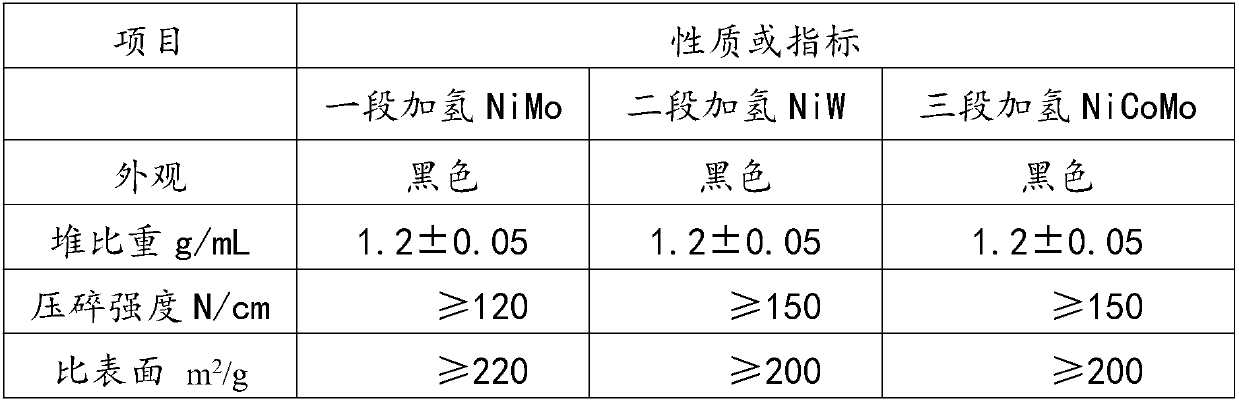

Method used

Image

Examples

Embodiment 1

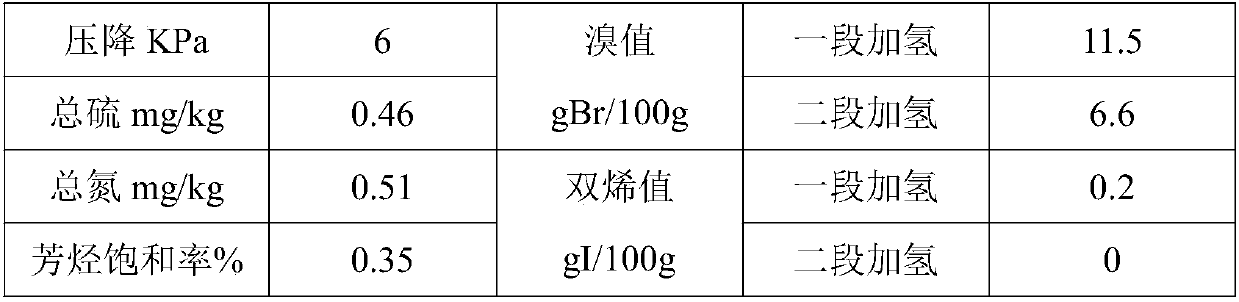

[0054] The raw material is coking crude benzene, and its composition and mass fraction are as follows: total aromatics 93.1%, diene value 2.5gI / 100g, bromine value 14.9gBr / 100g, total sulfur 2567mg / kg, total nitrogen content 589mg / kg. The hydrogenation reaction conditions are as follows: one-stage hydrogenation reaction temperature is 80℃, pressure is 2.0MPa, space velocity is 1.0h -1 , The hydrogen-to-oil ratio is 400:1; the second-stage hydrogenation reaction temperature is 190℃, the pressure is 4.0MPa, and the space velocity is 1.0h -1 , Hydrogen-oil ratio 600:1; three-stage hydrogenation reaction temperature is 270℃, pressure is 3.0MPa, and space velocity is 1.0h -1 , The ratio of hydrogen to oil is 600:1. After 120 days of continuous operation of the hydrogenation reaction, the results are shown in Table 2.

[0055] Table 2 Example 1 Hydrogenation results

[0056]

Embodiment 2

[0058] The raw material is coking crude benzene, and its composition and mass fraction are as follows: total aromatics 63.1%, diene value 10.5gI / 100g, bromine value 79.4gBr / 100g, total sulfur 3567mg / kg, total nitrogen content 889mg / kg. The hydrogenation reaction conditions are: one-stage hydrogenation reaction temperature is 130℃, pressure is 4.0MPa, and space velocity is 0.5h -1 , The hydrogen-to-oil ratio is 800:1; the second-stage hydrogenation reaction temperature is 220℃, the pressure is 2.0MPa, and the space velocity is 1.5h -1 , Hydrogen to oil ratio 800:1; three-stage hydrogenation reaction temperature 310℃, pressure 2.0MPa, space velocity 0.5h -1 , The ratio of hydrogen to oil is 300:1. After 120 days of continuous operation of the hydrogenation reaction, the results are shown in Table 3.

[0059] Table 3 Example 2 Hydrogenation results

[0060]

Embodiment 3

[0062] The raw material is coking crude benzene blended with other materials, and its composition and mass fraction are as follows: total aromatics 53.1%, diene value 12gI / 100g, bromine value 51.4gBr / 100g, total sulfur 5567mg / kg, total nitrogen content 789mg / kg. The hydrogenation reaction conditions are as follows: one-stage hydrogenation reaction temperature is 150℃, pressure is 3.0MPa, space velocity is 2.0h -1 , The hydrogen-oil ratio is 600:1; the second-stage hydrogenation reaction temperature is 170℃, the pressure is 3.0MPa, and the space velocity is 2.0h -1 , Hydrogen to oil ratio 400:1; three-stage hydrogenation reaction temperature 350℃, pressure 4.0MPa, space velocity 2.0h -1 , The ratio of hydrogen to oil is 450:1. After 120 days of continuous operation of the hydrogenation reaction, the results are shown in Table 4.

[0063] Table 4 Example 3 Hydrogenation results

[0064]

[0065]

[0066] It can be seen from the above three examples that after 120 days of continuous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com