A kind of coal tar pretreatment method

A technology for pretreatment and coal tar, applied in the field of coal chemical industry, can solve the problems of poor purification and separation effect, unable to operate for a long time, unable to meet feeding requirements, etc., and achieve the effects of improving liquid yield, good economic benefits and environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

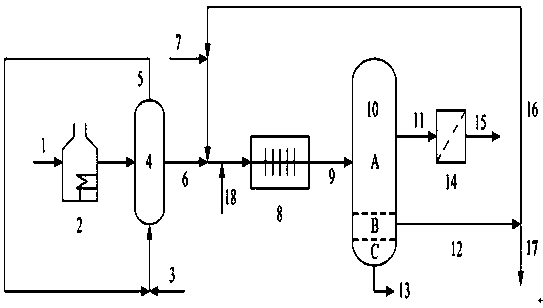

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, a coal tar pretreatment process is used for testing. The medium and low temperature coal tar produced by coal dry distillation in Xinjiang was selected as the test raw material. The properties of the whole fraction of coal tar are shown in Table 1. The coal tar raw material is heated to 80°C, the pretreatment gas is chlorine gas, the reaction pressure of the pretreatment reactor is 0.1MPa, the reaction temperature is 80°C, the gas-oil ratio is 1:1, the pretreatment gas is in countercurrent contact with the coal tar, and the acidic substance is inorganic acid Hydrochloric acid, the concentration of hydrochloric acid aqueous solution is 1.0%, the mass ratio of hydrochloric acid aqueous solution to coal tar is 2:1, the coal tar obtained after reacting with the pretreatment gas and hydrochloric acid aqueous solution are passed into the static mixer, and after being fully mixed, enter the sedimentation Separator, the temperature of the sedimentation separ...

Embodiment 2

[0037] The whole distillate coal tar is heated to 100°C, the pretreatment gas is chlorine dioxide, the reaction pressure of the pretreatment reactor is 1.0MPa, the reaction temperature is 100°C, the gas-oil ratio is 50:1, the pretreatment gas is in countercurrent contact with the coal tar, and the acidic substance Select inorganic acid sulfuric acid, the concentration of sulfuric acid aqueous solution is 2.5%, the mass ratio of sulfuric acid aqueous solution to coal tar is 3:10, and the coal tar obtained after reacting with the pretreatment gas and sulfuric acid aqueous solution are passed into the static mixer together, and after fully mixing Enter the sedimentation separator, the temperature of the sedimentation separator is 100°C, and it is divided into three layers in the sedimentation separator. The property analysis of the above-water oil and the underwater oil is shown in Table 3.

Embodiment 3

[0043] The whole distillate coal tar is heated to 120°C, the pretreatment gas is sulfur trioxide, the reaction pressure of the pretreatment reactor is 0.5MPa, the reaction temperature is 120°C, the gas-oil ratio is 200:1, the pretreatment gas is in countercurrent contact with the coal tar, and the acidic substance The organic acid formic acid is selected, the concentration of formic acid aqueous solution is 5.0%, the mass ratio of formic acid aqueous solution and coal tar is 1:2, and the coal tar obtained after reacting with the pretreatment gas and formic acid aqueous solution are passed into the static mixer together, and after fully mixing Enter the sedimentation separator, the temperature of the sedimentation separator is 80°C, and it is divided into three layers in the sedimentation separator. The property analysis of the oil on the water and the oil under the water is shown in Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com