Azobenzene polymer material and preparation method and applications thereof

A polymer material, azobenzene technology, applied in the field of photo-responsive polymer materials, can solve the problems of high energy consumption, high cost, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

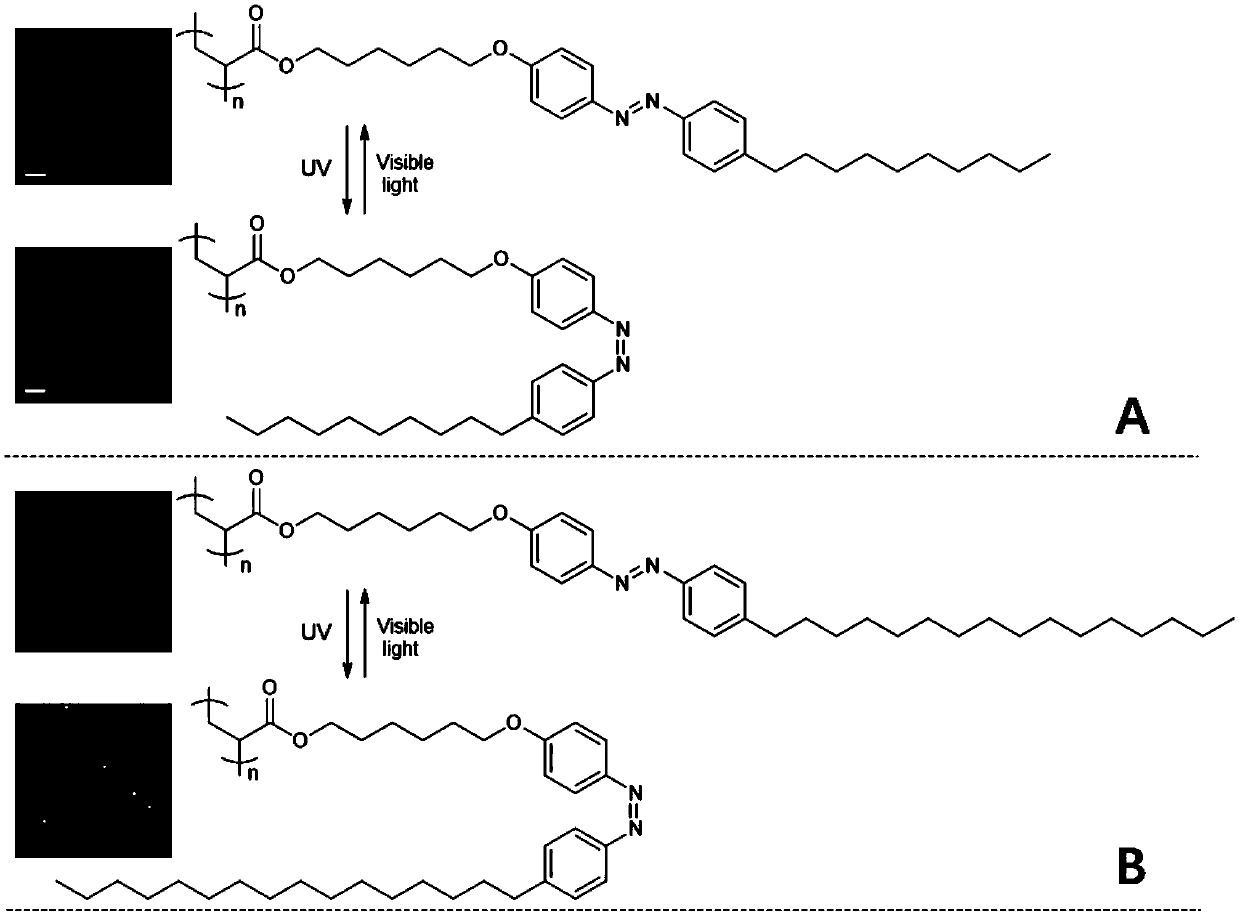

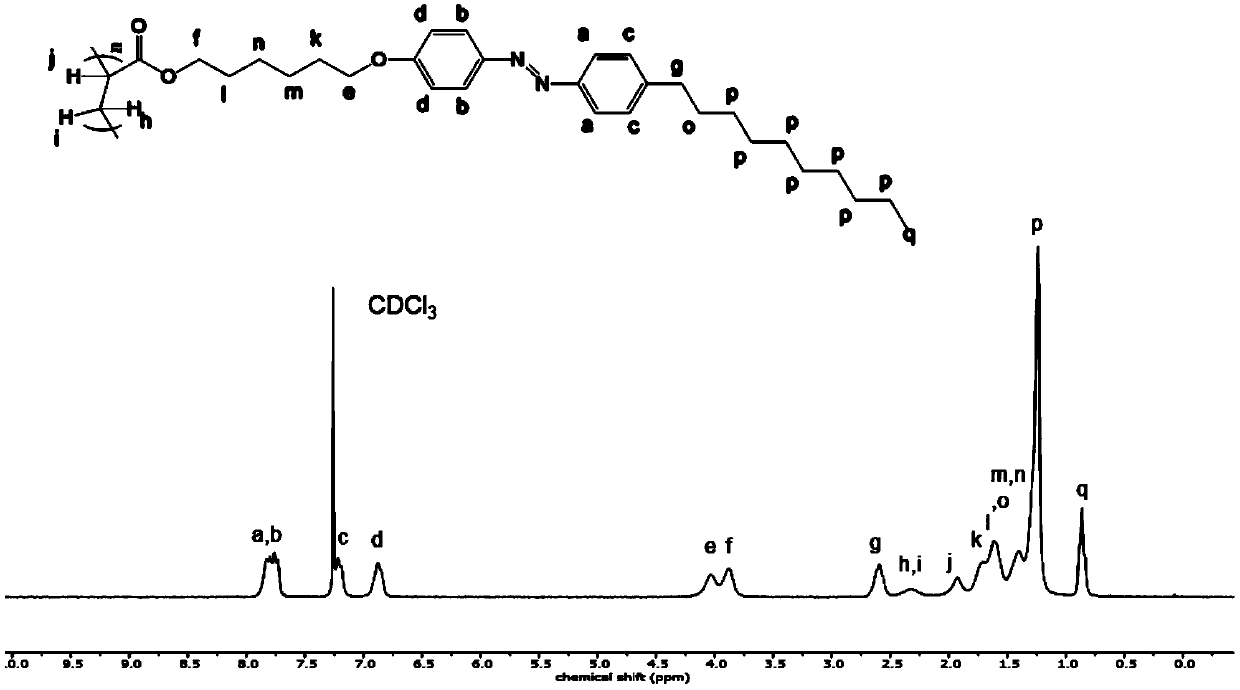

[0045] The synthetic method of azobenzene polymer A:

[0046] 1) Dissolve 0.075mol of n-decylaniline in a mixture of 16mL of hydrochloric acid, 16g of ice and 110mL of acetone, slowly add dropwise to the above solution a mixed solution of 28mL of water, 28g of ice and 0.075mol of sodium nitrite, and the system is at -5 Stir at ~0°C for 30 minutes, then dissolve 0.075mol phenol in 2mol / L sodium hydroxide solution, add to the above system, stir and react for 2 hours under the condition of pH 9-10, stop the reaction, add hydrochloric acid for neutralization, and the reaction solution is pumped The crude product was obtained by filtering and washing with water. The crude product was recrystallized from ethanol after drying to obtain 4-(4-n-decylbenzene)azophenol.

[0047] 2) Dissolve 0.036 mol of the final product of step 1) in 40 mL of N,N-dimethylformamide, then add 0.036 mol of potassium carbonate, and stir at 30° C. for 30 min. Add 0.09mol potassium iodide and 0.039mol 6-chl...

Embodiment 2

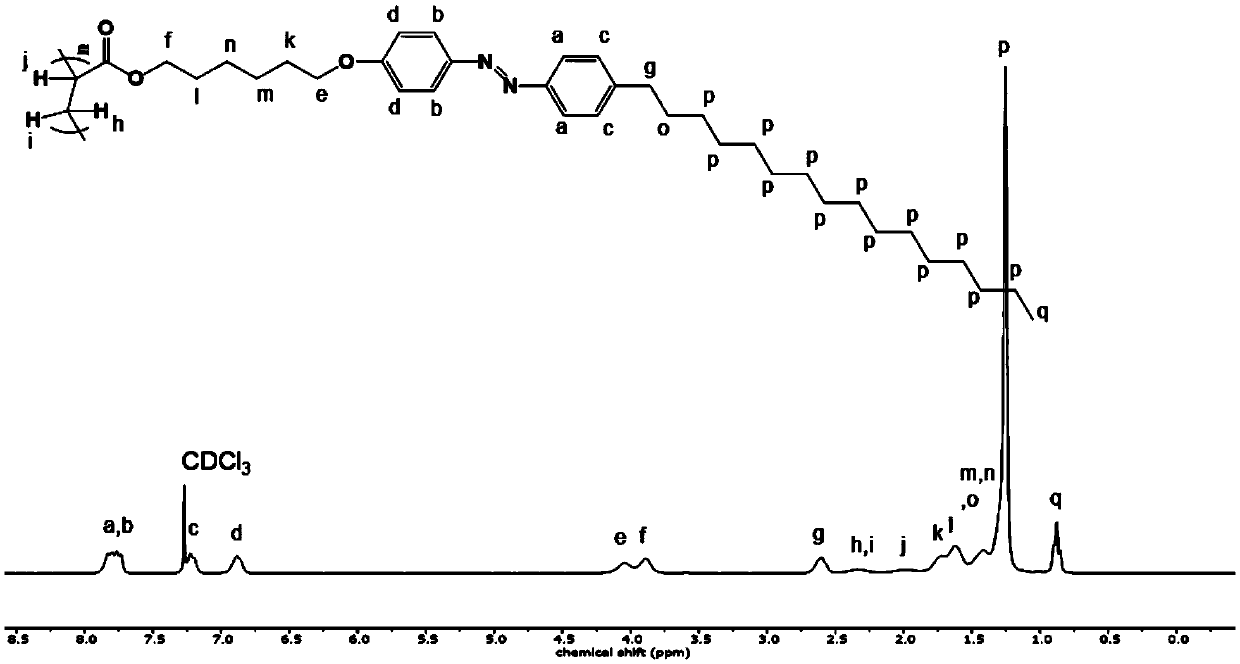

[0051] The synthetic method of azobenzene polymer B:

[0052] 1) Dissolve 0.075mol of p-hexadecylaniline in a mixture of 16mL of hydrochloric acid, 16g of ice and 110mL of acetone, slowly add dropwise to the above solution a mixed solution of 28mL of water, 28g of ice and 0.075mol of sodium nitrite, and the system is in - Stir at 5-0°C for 30 minutes, then dissolve 0.075mol phenol in 2mol / L sodium hydroxide solution, add to the above system, stir and react for 2 hours under the condition of pH 9-10, then stop the reaction, add hydrochloric acid to neutralize, and the reaction solution is passed through The crude product was obtained by suction filtration and washing with water. The crude product was recrystallized from ethanol after drying to obtain 4-(4-n-hexadecylbenzene)azophenol.

[0053] 2) Dissolve 0.036 mol of the final product of step 1) in 40 mL of N,N-dimethylformamide, then add 0.036 mol of potassium carbonate, and stir at 30° C. for 30 min. Add 0.09mol potassium ...

Embodiment 3

[0057] Azobenzene polymers A and B realize self-healing methods: at room temperature, scratch the surface of the polymer solid sample, first use 365nm (30mW / cm 2 ) irradiate the damaged part with ultraviolet light for 10s to cause photoisomerization, solid-liquid transition, repair the damage, and then use 530nm (2mW / cm 2 ) irradiated with visible light to make the cis-azobenzene polymer return to the trans-solid, realizing self-healing. see details Figure 4 .

[0058] The solid-liquid transition time is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com