Composite well cementing prepad fluid system and flushing method thereof

A cementing pre-fluid and system technology, which is applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problem of reduced cementing interface cementation strength, weak drilling fluid mud cake scouring ability, and inability to Drilling fluid cleaning and other issues to achieve the effect of improving displacement efficiency, ensuring safety, and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

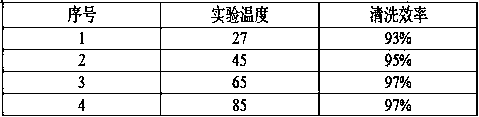

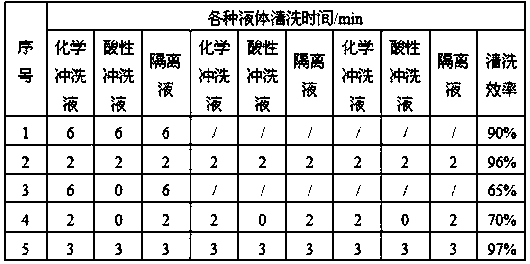

Examples

Embodiment 1

[0030] This embodiment provides a composite cementing prefluid system, which includes acid flushing fluid, chemical flushing fluid and spacer fluid pumped in alternately.

[0031] In order to strengthen the protection of the reservoir and reduce the pollution of the drilling fluid to the formation, the general completion drilling fluid uses calcium carbonate as the weighting material, so the main skeleton materials in the mud cake are calcium carbonate particles and clay. The invention adopts the acid flushing liquid to effectively decompose the calcium carbonate particles in the mud cake, thereby improving the flushing efficiency.

[0032] The acid in the acidic flushing fluid can react with the calcium carbonate in the mud cake of the wellbore drilling fluid to generate calcium ions and carbon dioxide gas, and decompose the calcium carbonate particles in the mud cake to make the mud cake loose and easy to wash and peel off. At the same time, the calcium ions generated by the ...

Embodiment 2

[0035] On the basis of Example 1, this example provides a composite cementing prefluid system, the acid flushing fluid is composed of the following components in parts by weight: anionic surfactant 4-10%, hydrochloric acid 8- 30%, inorganic salt 5-10%, and the balance is water, wherein the mass concentration of hydrochloric acid is 10-36%.

[0036] Among them, hydrochloric acid can react with calcium carbonate in the mud cake of the wellbore drilling fluid to generate calcium ions and carbon dioxide gas, and decompose the calcium carbonate particles in the mud cake to make the mud cake loose and easy to wash and peel off. At the same time, the calcium ions generated by the reaction can promote the hydration of cement slurry reaction, thereby further improving the bonding quality of the two interfaces. The surfactant is beneficial to improve the cleaning and scouring effect on the interface, improve the wettability of the interface, increase the penetration of the mud cake on t...

Embodiment 3

[0038] On the basis of Example 1, this example provides a composite cementing prefluid system, the chemical flushing fluid is composed of the following components in parts by weight: surfactant 3-10%, inorganic salt 5- 10%, mud dilution material 3-7%, and the balance is water.

[0039] Among them, the anionic surfactant can effectively remove the oil film on the borehole wall; the mud fluid dilution material can improve the fluidity of the drilling fluid and improve the displacement efficiency of the drilling fluid. At the same time, the chemical flushing fluid can isolate the drilling fluid and the acid flushing fluid to prevent the acid flushing fluid from polluting the drilling fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com