Lysine decarboxylase strain and application thereof in production of pentamethylenediamine

A technology of lysine decarboxylase and pentamethylenediamine, which is applied in the direction of application, microbial-based methods, enzymes, etc., can solve the problems of low production efficiency of pentamethylenediamine and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

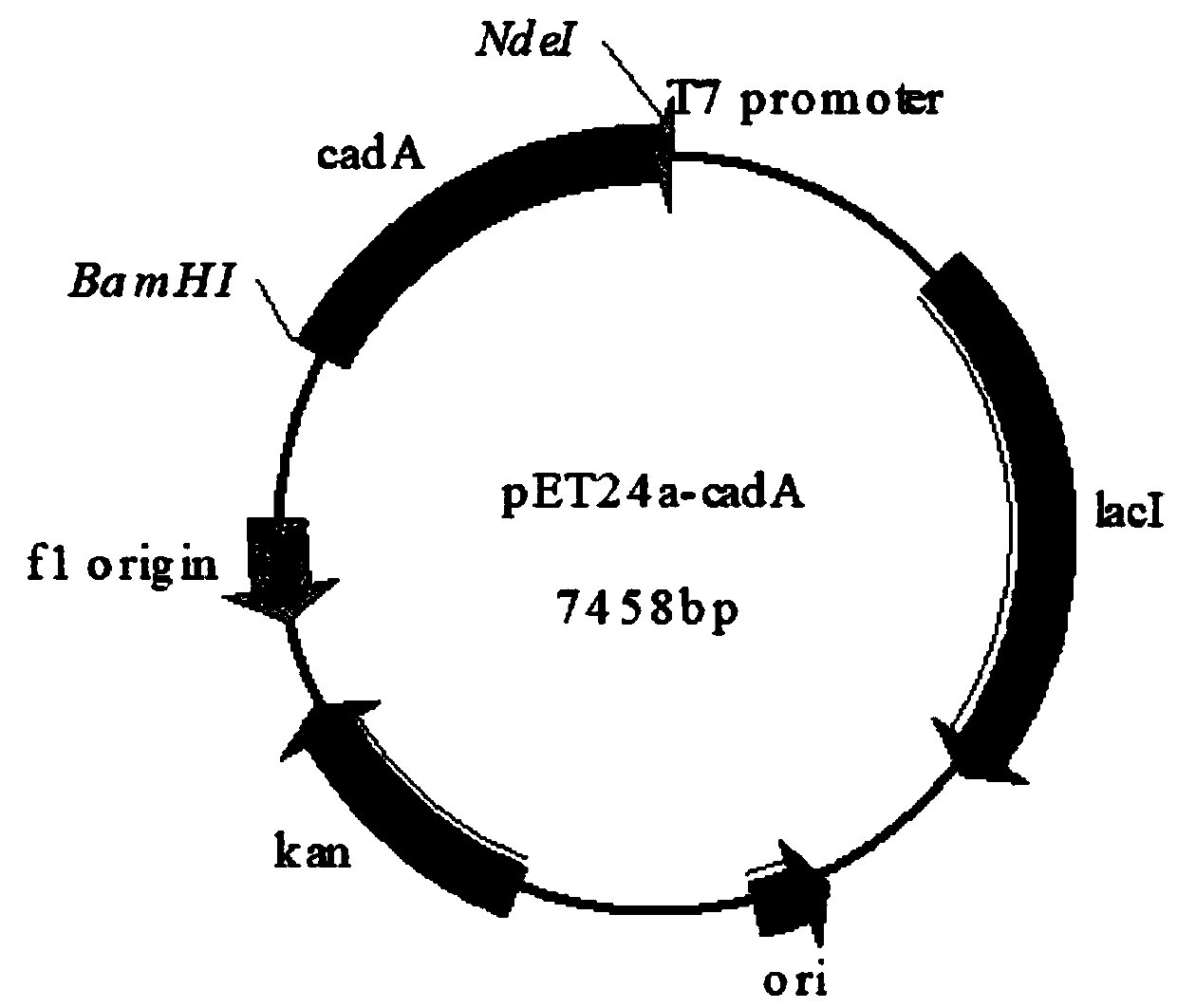

[0038] Example 1: Acquisition of lysine decarboxylase initial strain E.coli BL21(DE3) / pET24a-cadA

[0039] According to the gene sequence (NCBI accession number NC_000913.3) (SEQ ID NO: 1) of the lysine decarboxylase cadA (NCBI accession number NC_000913.3) (SEQ ID NO: 1) of E. 2) and cadA-BamHI-R (SEQ ID NO: 3): cadA-NdeI-F: 5'-GGAATTCCATATGaacgttattgcaatattg-3' cadA-BamHI-R: 5'-CGGGATCCttattttttgctttcttctttc-3'

[0040]The PCR reaction system includes: 50 pmol each of cadA-NdeI-F and cadA-BamHI-R, 1 μL of E.coli MG1655 bacterial solution, 1× KOD FX buffer, 0.2 mM dNTPs, 2% DMSO, 1 μL of each 10 μM primer, KOD FX neo 0.5 U, add water to 50 μL of the total system.

[0041] The PCR reaction conditions are: 94°C, 2min; 98°C for 10s, 55°C for 30s, 68°C for 1min15s, 30 cycles; 68°C for 7min.

[0042] After the PCR reaction, analyze with agarose gel electrophoresis, and detect a target-specific band of about 2148bp, which is required. The PCR amplified product was recovered with...

Embodiment 2

[0044] Embodiment 2: BL21(DE3) / pET24a-cadA engineering bacteria culture preparation

[0045] The lysine decarboxylase strain stored in the glycerol tube was inoculated in the LB medium added with kanamycin, activated at 37° C. at 220 rpm for 12 hours. The strain activated for 12 hours was inoculated into a Erlenmeyer flask with a liquid volume of 150 mL of seed medium, with an inoculum volume of 5%, and cultured in a constant temperature incubator at 37° C. with shaking at 140 rpm. The bacterial cells cultured for 14 h were collected by centrifugation at 4000 rpm, and washed once with sterile saline. Use pH 6.5 phosphate buffer to make 108 / mL bacterial suspension;

Embodiment 3

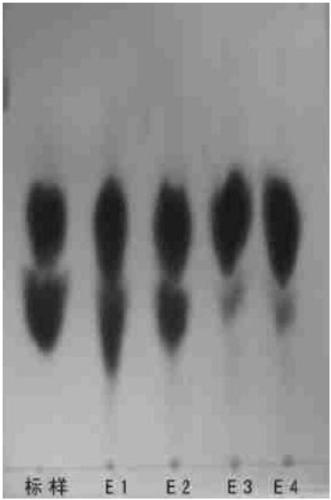

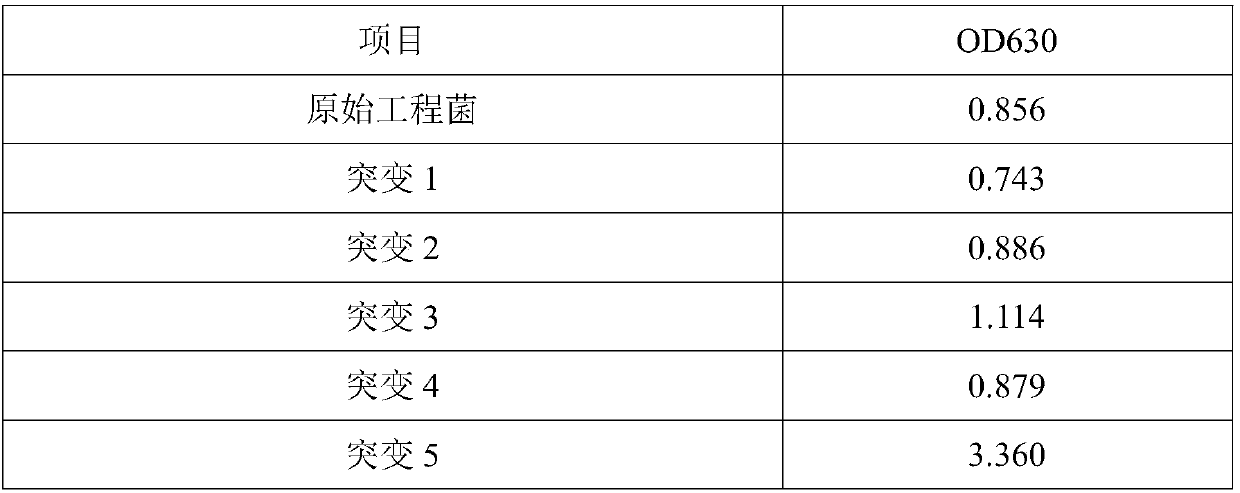

[0046] Embodiment 3: mutagenesis treatment

[0047] Take 5 mL of the bacterial suspension and add it to a 15 mm sterile test tube, add 0.5% NTG diluted culture solution and shake for 2 h, dilute a large amount to terminate the mutagenesis, spread on the screening plate and culture for 1 d.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com