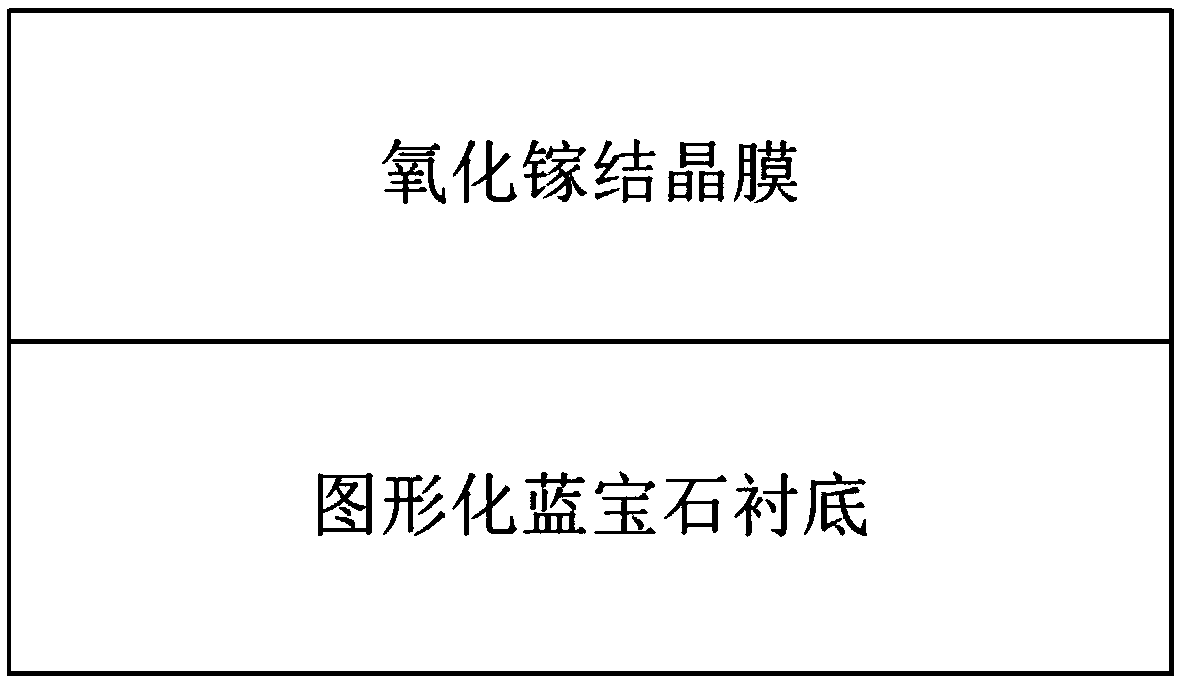

Gallium oxide semiconductor laminated structure and preparation method thereof

A stacked structure, gallium oxide technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., to achieve the effects of inhibiting formation, improving growth advantages, and preventing phase mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

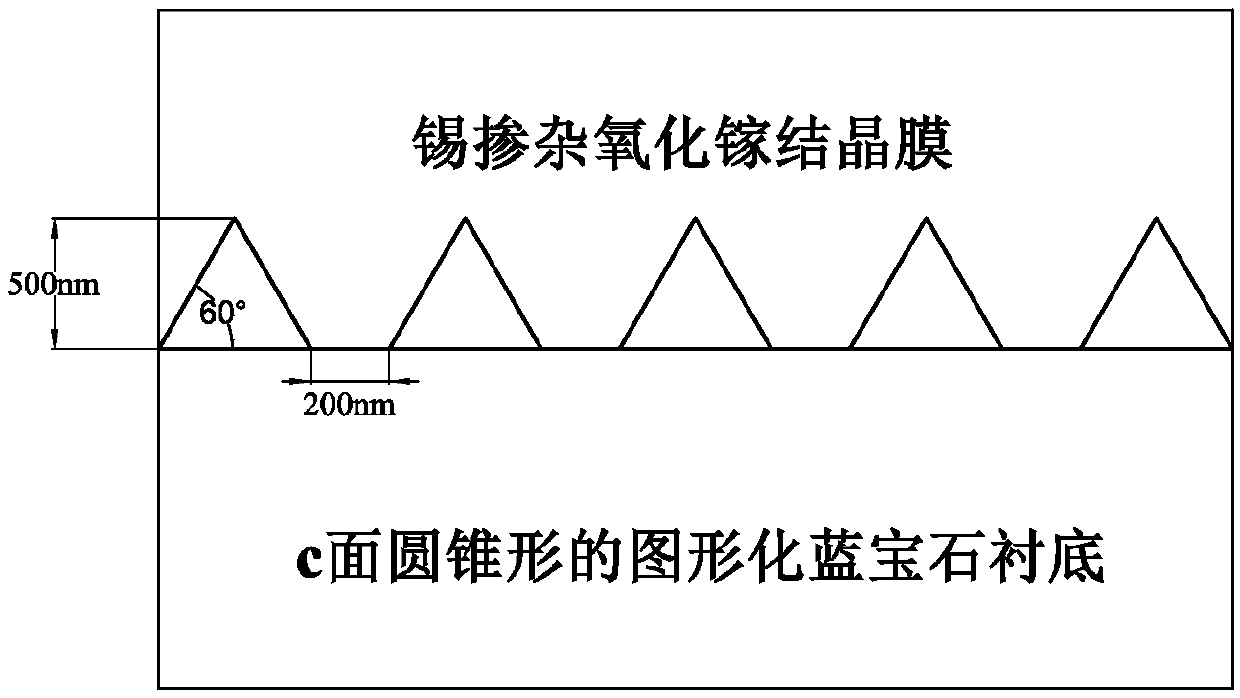

Embodiment 1

[0043] Using existing MOCVD equipment, using organometallic trimethylgallium as the gallium source, oxygen as the oxygen source, tetrakis(dimethylamino)tin as the doping source, and argon with a purity of more than 99.999% as the carrier gas and growth protection atmosphere, A high-quality tin-doped gallium oxide crystalline film is grown on a conical patterned sapphire substrate.

[0044] The preparation method of gallium oxide crystal film is as follows:

[0045]Step 1: Select a c-plane conical patterned sapphire substrate, firstly, ultrasonically clean the substrate in acetone solution for 3-10 minutes; secondly, ultrasonically clean it in isopropanone solution for 3-10 minutes; The substrate is ultrasonically cleaned in hydrochloric acid and hydrogen peroxide solution, sulfuric acid and hydrogen peroxide solution for 3-10 minutes, and finally the substrate is taken out and dried with nitrogen gas to complete the cleaning.

[0046] Step 2: Manipulating the MOCVD equipment,...

Embodiment 2

[0056] Using existing MOCVD equipment, using organic metal triethylgallium as gallium source, deionized water as oxygen source, argon with a purity of 99.999% or more as carrier gas and growth protection atmosphere, on a hexagonal patterned sapphire substrate Gallium oxide crystal film was grown on it.

[0057] The preparation method of gallium oxide crystal film is as follows:

[0058] Step 1: Select a c-plane hexagonal patterned sapphire substrate, firstly, ultrasonically clean the substrate in acetone solution for 3-10 minutes; secondly, ultrasonically clean it in isopropanone solution for 3-10 minutes; The substrate was ultrasonically cleaned in hydrochloric acid and hydrogen peroxide solution, sulfuric acid and hydrogen peroxide solution for 3-10 minutes, and finally the substrate was taken out and dried with nitrogen gas to complete the cleaning.

[0059] Step 2: Manipulate the MOCVD equipment, send the substrate into the reaction chamber, and let the tray rotate at a s...

Embodiment 3

[0071] Compared with Example 1, other conditions are the same, except that the substrate is a c-plane hemispherical patterned sapphire substrate.

[0072] see Figure 8 , is a schematic diagram of the laminated structure of a gallium oxide crystal film grown on a hemispherical patterned sapphire substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com