Concentrated feed for milk producing cows and preparation method thereof

A technology of concentrated feed and dairy cows, applied in animal feed, animal feed, additional food elements, etc., can solve the problems of reducing the resistance of dairy cows, weak feed digestibility, and affecting the breeding environment, so as to improve the immunity of dairy cows and improve Feed conversion rate, effect of increasing feed intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

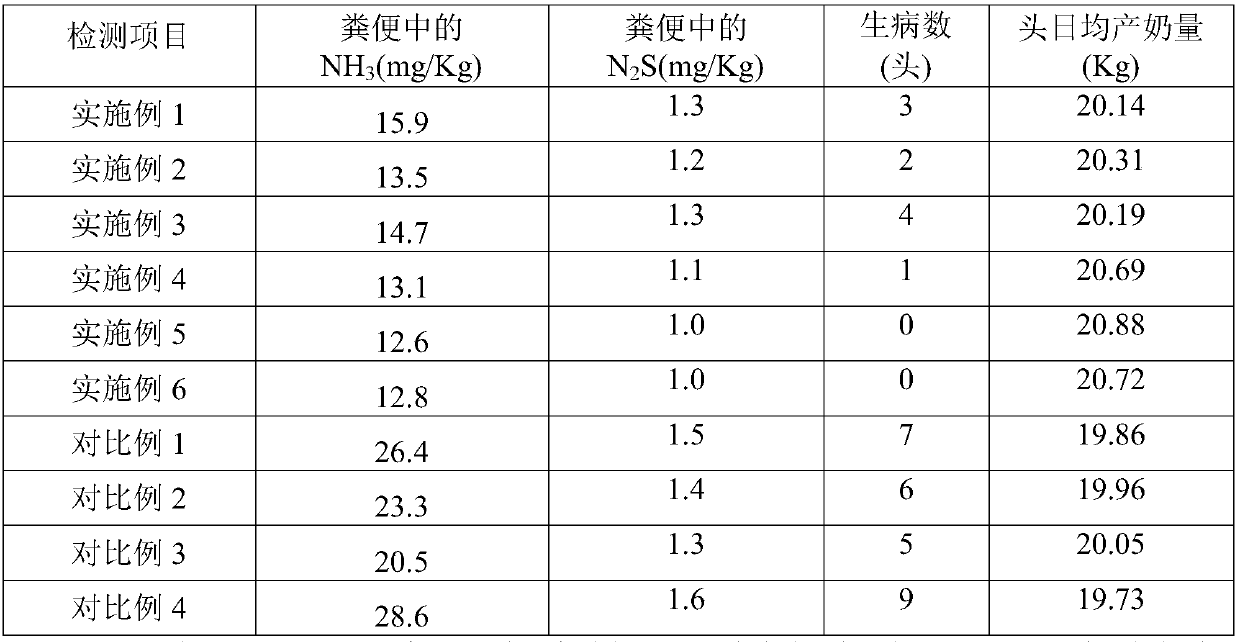

Examples

Embodiment 1

[0040] A concentrated feed for dairy cows, comprising the following components in parts by weight: main ingredients, 7 parts of baking soda, 35 parts of stone powder, 10 parts of glucose, 8 parts of sodium chloride, 18 parts of molasses and 90 parts of chlorella liquid , wherein the main ingredients include 142 parts of sprayed corn husks, 150 parts of corn DDGS, 308 parts of soybean meal, 95 parts of cottonseed meal, 75 parts of palm meal, 50 parts of sesame meal, and 18 parts of glutamic acid residue. The number of active chlorella in the algae liquid is ≥10 4 a / mL;

[0041] The preparation method comprises: mixing various preparation raw materials to obtain concentrated feed for dairy cows, and the mixing temperature is 25°C.

Embodiment 2

[0043] A concentrated feed for dairy cows, comprising the following components in parts by weight: main ingredients, 8 parts of baking soda, 38 parts of stone powder, 12 parts of glucose, 10 parts of sodium chloride, 20 parts of molasses and 105 parts of chlorella liquid , wherein the main ingredients include 146 parts of sprayed corn husks, 156 parts of corn DDGS, 316 parts of soybean meal, 102 parts of cottonseed meal, 84 parts of palm meal, 66 parts of sesame meal, and 22 parts of glutamic acid residue. The order of magnitude of active chlorella in the algae liquid is 10 4 a / mL;

[0044] The preparation method comprises: mixing various preparation raw materials to obtain concentrated feed for dairy cows, and the mixing temperature is 27°C.

Embodiment 3

[0046] A concentrated feed for dairy cows, comprising the following components in parts by weight: main ingredients, 10 parts of baking soda, 42 parts of stone powder, 15 parts of glucose, 12 parts of sodium chloride, 22 parts of molasses and 110 parts of chlorella liquid , wherein the main ingredients include 156 parts of sprayed corn husks, 160 parts of corn DDGS, 322 parts of soybean meal, 105 parts of cottonseed meal, 90 parts of palm meal, 70 parts of sesame meal, and 25 parts of glutamic acid residue. The order of magnitude of active chlorella in the algae liquid is 10 4 a / mL;

[0047] The preparation method comprises: mixing various preparation raw materials to obtain concentrated feed for dairy cows, and the mixing temperature is 30°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com