NTA-based (nitrilotriacetate) IMAC (immobilized metal affinity chromatography) filler and preparation method and application thereof

A matrix and aldehyde-based technology, applied in the field of NTA-based IMAC filler and its preparation, can solve the problems of high raw material costs and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

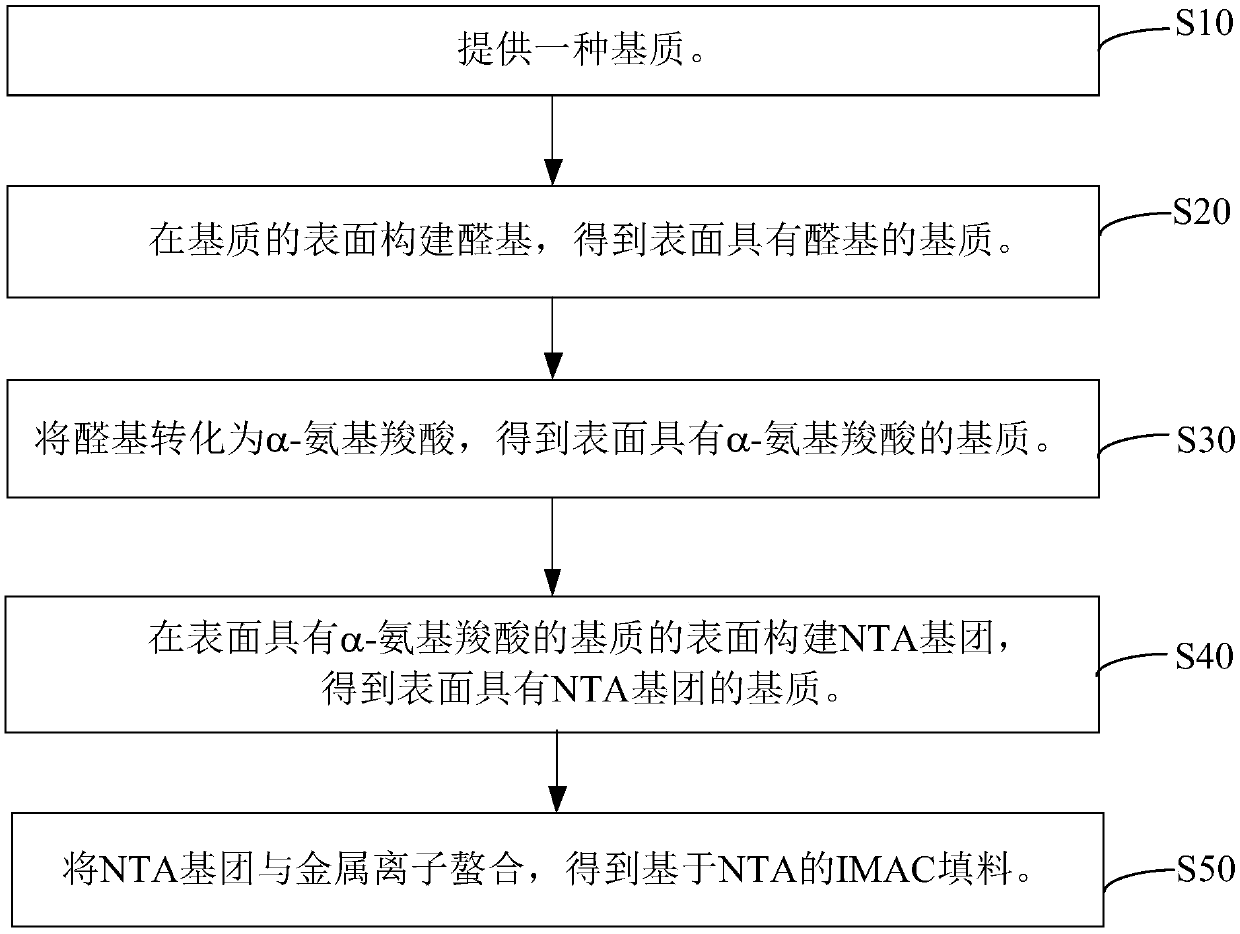

[0029] See figure 1 , a kind of preparation method of the NTA-based IMAC filler of one embodiment of the present invention, comprises the steps:

[0030] S10. A matrix is provided.

[0031] Preferably, the matrix is a polymer matrix with hydroxyl groups on the surface or a polymer matrix with epoxy groups on the surface. The surface of the polymer matrix contains hydroxyl or epoxy groups, which is convenient for the next step of reaction.

[0032] Preferably, the polymer matrix is selected from one of polymethacrylate microspheres and polystyrene-divinylbenzene microspheres.

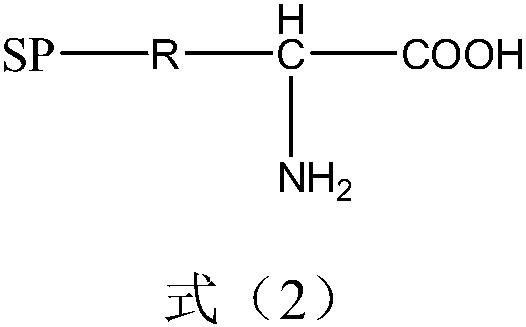

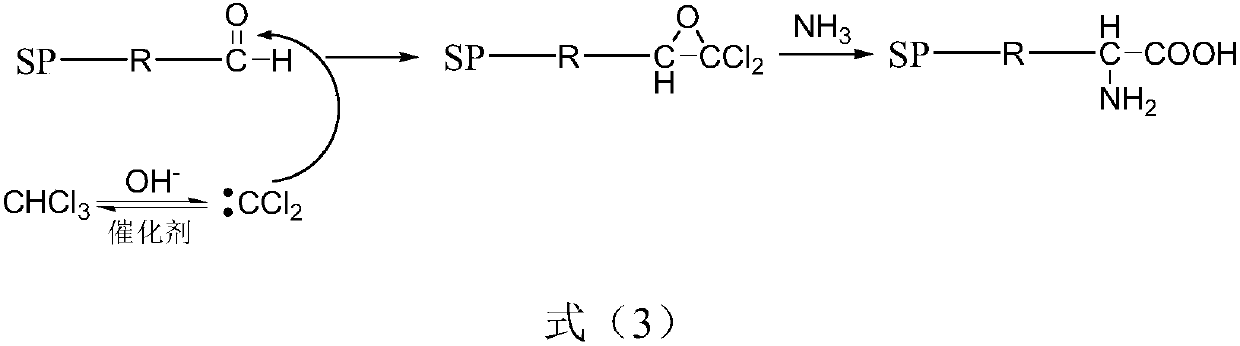

[0033] S20. Constructing aldehyde groups on the surface of the substrate to obtain a substrate with aldehyde groups on the surface. As shown in formula (1):

[0034] SP-R-CHO

[0035] Formula 1)

[0036] Among them, SP represents the substrate, and R represents the connecting arm between the substrate and the aldehyde group.

[0037] Preferably, when the substrate is a polymer substrate cont...

Embodiment 1

[0067] The polymethacrylate microspheres used in this example, the model is Monomix MC30 (particle size is 30 μm, pore size is 100 nm, the surface contains a lot of hydroxyl groups, and the color is white); the manufacturer is Suzhou Saifen Technology Co., Ltd. self-made. All other raw materials are commercially available.

[0068] Weigh 100g of polymethacrylate microspheres with a balance, transfer to a 500mL three-neck flask, add 100mL of 0.6M NaOH solution (containing 2mg / mL NaBH 4 ), then add 100mL 1,4-butanediol diglycidyl ether, and react at 37°C with 100rpm mechanical stirring for 4h. Wash 3 times with deionized water until neutral. Then the solid product obtained was added to a 1000mL three-necked flask, and 300mL of 0.5M H 2 SO 4 The solution was reacted at a temperature of 50° C. with 100 rpm mechanical stirring for 2 hours. After the reaction, the reaction solution was drained with a Buchner funnel to keep the solid product, and washed with deionized water until ...

Embodiment 2

[0074] The polymethacrylate microspheres used in this example, the model is Monomix MC30-Epoxy (particle size is 30 μm, pore size is 100 nm, the surface contains epoxy groups, and the color is white); the manufacturer is Suzhou Saifen Technology Co., Ltd. Prepare yourself. All other raw materials are commercially available.

[0075] Weigh 100g of polymethacrylate microspheres with a balance, transfer to a 500mL three-necked flask, add 150mL of 0.1M sodium carbonate-sodium bicarbonate buffer solution, adjust the pH of the mixture to 10.5, then add 89.6g of glucosamine, and control the temperature 70°C, 100rpm mechanical stirring and reaction for 16h. After the reaction, use a Buchner funnel to dry it, keep the solid product, and wash it with deionized water for 5 times to obtain polymethacrylate microspheres with aldehyde groups on the surface.

[0076] The rest of the experimental steps were consistent with the corresponding experimental steps in Example 1 to obtain the NTA-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com