Method of preparing EuB6 nano cubic crystal at low temperature

A nano-cube and crystal technology, applied in the field of low-temperature preparation of EuB6 nano-cube crystals, can solve the problems of energy consumption and non-greenness, and achieve good antibacterial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) 2mmol EuCl 3 , 0.04mmol PVP (molecular weight is 8000) and 0.04mmol potassium sulfate are mixed in 20mL ionic liquid, stir 10 minutes under argon protection, to form a solution;

[0033] (2) Under the protection of argon, transfer the mixed solution of step (1) into a 50mL reaction kettle, feed borane, and make 30mmol borane and EuCl 3 Closed reactor;

[0034] (3) Open the liquid phase plasma, the power is 500W, and the mixed solution in the reaction kettle of step (2) is at 60 After being processed for 45min, the prepared product was obtained;

[0035] (4) Wash the product three times with deionized water, then three times with absolute ethanol, and dry it for later use.

Embodiment 2

[0037] (1) 2mmol EuCl 3 , 0.04mmol PVP (molecular weight is 8000) and 0.04mmol potassium sulfate are mixed in 20mL ionic liquid, stir 10 minutes under argon protection, to form a solution;

[0038] (2) Under argon protection, transfer the mixed solution of step (1) into a 50mL reaction kettle, feed borane, and make 20mmol borane and EuCl 3 Closed reactor;

[0039] (3) Open the liquid phase plasma, the power is 500W, and the mixed solution in the reaction kettle of step (2) is at 60 After being processed for 45min, the prepared product was obtained;

[0040] (4) Wash the product three times with deionized water, then three times with absolute ethanol, and dry it for later use.

Embodiment 3

[0042] (1) 2mmol EuCl 3 , 0.04mmol PVP (molecular weight is 8000) and 0.04mmol potassium sulfate are mixed in 20mL ionic liquid, stir 10 minutes under argon protection, to form a solution;

[0043] (2) Under argon protection, transfer the mixed solution of step (1) into a 50mL reaction kettle, feed borane, and make 40mmol borane and EuCl 3 Closed reactor;

[0044] (3) Open the liquid phase plasma, the power is 500W, and the mixed solution in the reaction kettle of step (2) is at 60 After being processed for 45min, the prepared product was obtained;

[0045] (4) Wash the product three times with deionized water, then three times with absolute ethanol, and dry it for later use.

[0046] EuB of the present invention 6 Properties of nanocube crystals:

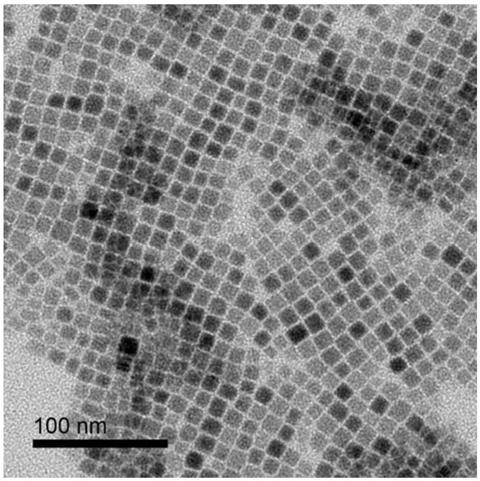

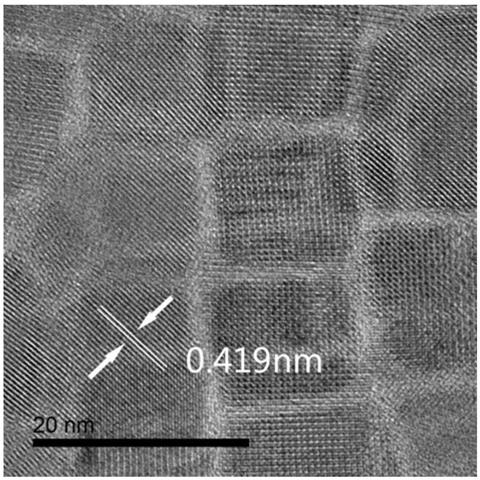

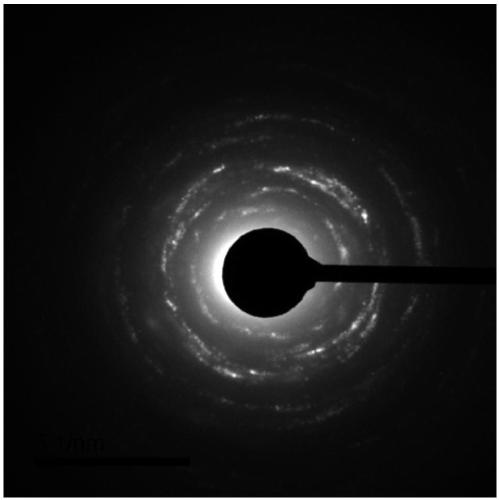

[0047] The material prepared in Example 1 was characterized by TEM, figure 1 It is a low magnification TEM image of the sample, it can be seen that EuB 6 The nanocube particles were successfully prepared, and the average pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com